Milk is the most nourishing of all foods and a favorite drink of people throughout the world. Milk has almost all the nutrients (nourishing substances) that human beings need for growth and good health. In addition, milk has most of these nutrients in large amounts and in such proportions that they can work as a team to help keep the body strong and healthy.

All female mammals produce milk to nourish their young. But when we think of milk, we generally think of the milk that comes from cows. Cows provide most of the milk used in the United States, Canada, and many other countries. In some parts of the world, however, other animals produce the main supply of milk. Goat milk is popular in parts of Europe, Latin America, Africa, and Asia. Camels provide milk in the desert lands of Arabia, central Asia, and northern Africa. Some South Americans drink llama milk. In Arctic regions, people get milk from reindeer. Sheep provide much of the milk in Greece, Iran, and Turkey. Water buffalo supply milk in Egypt, India, Pakistan, and many countries of Southeast Asia.

Butter, cheese, ice cream, yogurt, and several other foods are made from milk. Milk—or one of its products—is also an ingredient in many foods, such as cakes, casseroles, puddings, and sauces. Milk is also used in making numerous products besides food. For example, manufacturers use casein, the main protein in milk, to make waterproof glues, various plastics, and paints.

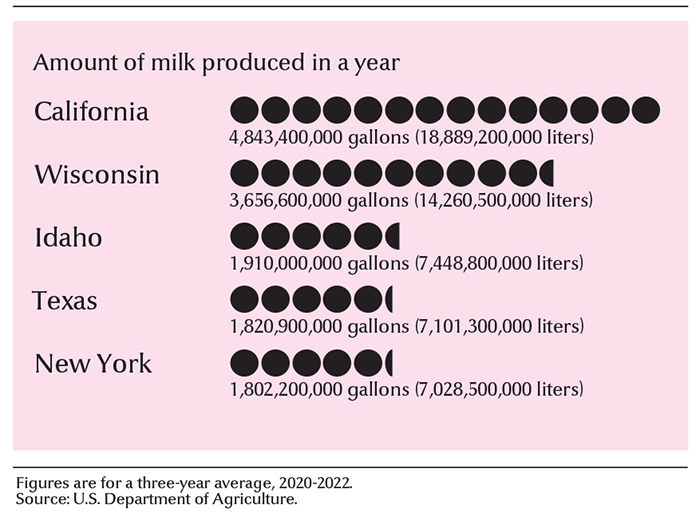

India and the United States are the world’s leading producers of cow’s milk. Brazil, China, Germany, and Russia also produce much milk. The United States dairy industry is concentrated in the Dairy Belt, which extends from New York to Minnesota. California and Wisconsin lead the states in milk production. Quebec and Ontario are Canada’s chief milk-producing provinces.

Food value of milk

This section discusses the nutrients in milk. It also examines the importance of milk in the human diet.

Nutrients in milk.

The body needs six kinds of nutrients for energy, growth, and the replacement of worn-out tissue. These nutrients are (1) water, (2) carbohydrates, (3) fats, (4) proteins, (5) minerals, and (6) vitamins. Milk has been called “the most nearly perfect food” because it is an outstanding source of these nutrients. But milk is not “the perfect food” because it lacks enough iron and does not provide all vitamins.

Water

is the most vital nutrient. The body needs water to carry out all its life processes. Cow’s milk is about 88 percent water.

Carbohydrates

are a major source of energy for the body. The carbohydrate content of milk is mainly lactose, also calledmilk sugar. In addition to providing energy, lactose helps the body absorb the minerals calcium and phosphorus in milk. Our bones and teeth consist largely of these minerals. Lactose also gives milk its sweet taste. See Carbohydrate.

Fats,

like carbohydrates, provide energy. They also supply certain substances called essential fatty acids_that the body must have. Fat gives milk its rich flavor. Milk fat also contains vitamins A, D, E, and K and several other substances. One such substance, _carotene, gives milk its golden tint. Milk fat appears as tiny globules. A drop of milk contains about 100 million such globules. See Fat .

Proteins

help the body grow and maintain itself. They also supply energy. The proteins in milk are complete proteins—that is, they contain all the amino acids (protein parts) needed for building blood and tissue. Only egg proteins and the proteins in some meats have a higher food value than milk proteins have. Casein makes up about four-fifths of the protein content of milk. It is found only in milk. See Protein .

Minerals,

like proteins, help the body grow and remain healthy. Calcium and phosphorus are the most important minerals in milk. In fact, milk is the chief food source of calcium. Other minerals in milk include potassium, sodium, and sulfur and smaller amounts of aluminum, copper, iodine, iron, manganese, and zinc.

Vitamins

are essential for growth, maintaining body tissue, and the prevention of such diseases as beriberi and rickets. Milk provides more vitamins—and in larger amounts—than do most other natural foods. Milk is an excellent source of vitamins A and B2 and a good source of vitamin B1. Other vitamins in milk include vitamins B6, B12, C, E, and K and niacin. Milk also has vitamin D, but the quantity is low. Most dairies add extra vitamins A and D to milk. See Vitamin.

All milk—human and animal—contains the same nutrients. The amounts differ, however. Compared with cow’s milk, for example, the milk from a water buffalo has 3 times as much fat and 11/2 times as much protein but only about three-fourths the sugar. Human milk has fewer proteins and minerals than cow’s milk but about 11/2 times as much sugar.

In the United States, the federal government requires that whole milk sold as food meet certain standards. The government specifies that whole milk must contain at least 3.25 percent milk fat and 8.25 percent nonfat milk solids. Some states require a higher percentage of nonfat milk solids in their milk. For example, California requires 8.7 percent nonfat milk solids in its whole milk. Most cow’s milk has about 3.7 percent milk fat, 4.6 percent lactose, 3.2 percent protein, and 0.7 percent minerals. The percentages differ somewhat between individual cows and breeds. The quality and composition of milk also depend on what a cow is fed and how the animal is cared for.

Milk in the human diet.

Milk is an important part of most people’s diet. It is the first food of newborn babies, whether they are breast-fed or bottle-fed. Because of its many nutrients, milk helps the body develop. Children who drink milk grow faster than other children who eat the same foods but drink no milk. Milk can also help people obtain nutrients their diet might otherwise lack.

Doctors and nutrition experts disagree on exactly how much milk a person should drink. In general, they recommend that children and teen-agers drink at least three 8-ounce (240-milliliter) glasses a day. Adults should have at least two glasses daily. Expectant mothers and mothers who are nursing their babies should drink three or four glasses a day.

Many people cannot drink the recommended amount of milk. In most people, for example, levels of lactase, the enzyme that breaks down milk sugar, decline with age. As a result, many adults and some children have a condition called lactose intolerance, which makes it difficult to digest milk. Lactose intolerance is especially common in Africa, Asia, and South America, and among people of African, Asian, or Native American descent elsewhere. In addition, a small percentage of people are allergic to the protein in milk. Both lactose intolerance and milk-protein allergy produce similar symptoms, including stomach pain and diarrhea.

Finally, many doctors recommend that patients who have a large amount of cholesterol in their bloodstream avoid drinking whole milk because of its cholesterol content. Cholesterol is a fatty substance that is found in all animal tissues. However, a high level of cholesterol in the blood may contribute to arteriosclerosis, a disease of the arteries that can cause heart attacks. Fat-free milk, also called skim milk, contains little cholesterol.

Milk from farm to table

Millions of people enjoy pure, fresh milk every day, especially at mealtimes. But few realize the many steps required—first at a dairy farm and then at a processing plant—to get this milk to the dining table.

At a dairy farm,

milk is produced under highly sanitary conditions by cows called dairy cattle. Most dairy cows in North America are the black and white Holstein breed. See Cattle (Dairy cattle).

Production.

Almost all dairy farmers in industrialized countries use milking machines to milk their cows. Machines are faster and more sanitary than milking by hand. In some countries, however, milking by hand is still widespread. See Milking machine.

The milk that cows produce is called raw milk until it has been pasteurized. Harmful bacteria grow rapidly in raw milk unless the milk is kept clean and cool. Dairy farmers therefore see that their cows and barns are clean, and they sanitize their milking equipment. Most farmers store raw milk in a refrigerated tank until it can be delivered to a processing plant. As a cow is milked, the milk flows into the tank and is cooled to less than 40 °F (4.4 °C).

Local, regional, and national government agencies set standards of cleanliness for dairy farms and processing plants. To make sure these standards are met, local health inspectors check farms and plants and conduct laboratory tests of milk. Cows are also tested periodically by veterinarians for two diseases, tuberculosis and brucellosis.

Almost all the fluid milk sold for table use in industrialized countries is classified as grade A or grade 1. Most communities have special rules regarding the sanitary conditions under which milk must be produced and processed to be classed as grade A or 1. In the United States, the rules are largely based on the Grade A Pasteurized Milk Ordinance, a set of recommendations developed by the Food and Drug Administration (FDA). The states voluntarily adopt this ordinance. Milk moves from state to state with few legal restraints. Representatives from various states work together to resolve problems concerning the sanitary quality of grade A milk.

Many states also permit the sale of a manufacturing grade of milk. It is used chiefly in making such dairy products as butter, cheese, and ice cream.

Marketing.

Many dairy farmers are members and joint owners of a dairy cooperative. A cooperative picks up the members’ raw milk and sells it for them at the highest price to processing plants. Some cooperatives not only pick up the members’ milk but also process it. See Cooperative.

Many governments set minimum prices that farmers receive for their milk. The U.S. government operates a price support program. Under this program, the government buys dairy products when the farm price of milk falls below a minimum. In the European Union, the Common Agricultural Policy guarantees farmers a minimum price for their milk. However, the policy also limits the quantity of milk that they can produce.

Transportation.

A dairy cooperative operates large tank trucks to transport the milk of its members. At least every other day, a truck picks up milk from various dairy farms in a local region and delivers it to a processing plant. The truck’s tank is insulated to keep the milk cold, even in hot weather. At each farm, the milk haulers examine and take samples of the milk before pumping it into the tank. The samples are important because all the milk from the various farms becomes mixed in the tank. The samples from each farm go to the local health department and to the milk processor to be tested for composition and quality.

At a processing plant.

Much of the milk produced worldwide is processed into various kinds of fluid milk or cream. Most of the rest is made into such dairy products as butter, cheese, and ice cream. A small amount is used to make special types of dairy products, such as acidophilus milk. This milk is often used for treating intestinal disorders. The following discussion describes the processing of fresh fluid milk. To learn how some other dairy products are made, see the table Kinds of milk and milk products in this article.

As soon as the tank truck arrives at a processing plant, laboratory technicians check the odor, taste, and appearance of the milk. They also measure the fat content, the number of bacteria, the amount of milk solids, and the residue of antibiotics that may have been given to the cattle to treat disease. Technicians further test the milk during and after processing. All this testing helps ensure the quality and purity of the milk. Milk is the most highly tested of all foods.

After the first tests, the milk is pumped into a large refrigerated storage tank. On its way to the tank, the milk passes through a clarifier. This machine removes any hair, dust, or similar matter that may be in the milk. After the milk is pumped from the storage tank, it goes through five basic steps. These steps, in order, are (1) separation or standardization, (2) pasteurization, (3) homogenization, (4) fortification, and (5) packaging.

Separation or standardization.

Some of the milk that comes from the storage tank is separated. The rest is standardized. In separation, the cream, or fat, is mechanically skimmed (separated) from milk. Some of the cream is then either bottled or used to make butter or other dairy products. Some of the remaining skim milk, which is fat-free milk, is also either bottled or used to make such foods as cottage cheese or cultured buttermilk. The rest of the cream and fat-free milk is used to standardize the milk that has not been separated.

In standardization, the fat content of milk is regulated. A device called a Milko-tester measures the fat content as the milk flows through a pipeline. If the content becomes lower than the desired level, cream is pumped in with the milk. If the fat content becomes higher, fat-free milk is pumped in. Standardization enables dairies to produce various types of lower-fat milks with a uniform fat content. It also ensures that the fat content of whole milk meets government requirements.

Pasteurization

involves heating milk to kill disease-causing bacteria. Nearly all milk sold in industrialized countries is pasteurized. Most is pasteurized by the high-temperature short-time, (HTST) method, which involves heating milk to 161 °F (72 °C) for 15 seconds and then quickly cooling it. Some milk is pasteurized by the batch method—that is, by heating it to 145 °F (63 °C) for 30 minutes. In a method called ultrapasteurization, milk is heated to at least 280 °F (138 °C) for 2 or more seconds and then cooled rapidly. Milk treated by any of these methods spoils quickly if not refrigerated. But milk pasteurized by the ultrahigh-temperature (UHT) method keeps for months without refrigeration. In this method, milk is heated to about 300 °F (149 °C) for 6 to 9 seconds, then cooled rapidly and stored in sterile containers. UHT-treated milk is also called sterilized milk.

Homogenization.

Almost all fluid milk sold in industrialized countries is homogenized. Homogenization breaks up the fat globules in milk so the globules do not rise to the top. A machine called a homogenizer forces the milk through tiny openings under great pressure. The process increases the number of fat globules and gives every drop of milk the same amount of cream. Milk that has been homogenized tastes richer than nonhomogenized milk.

Fortification

improves the food value of milk by adding certain nutrients, especially vitamins and proteins. Most dairies add vitamin D because the quantity is low in milk. They fortify fat-free milk with protein and vitamin A as well as vitamin D. A few dairies also add other vitamins and some minerals to milk.

Packaging

is the final step in the processing of milk. Automatic packaging machines fill and seal milk containers, most of which are bottles or paper cartons. Direct fluorescent light can damage milk that is packaged in certain kinds of plastic containers. It destroys some of the vitamins in milk and can change the milk’s flavor. Some plastic containers consist of materials that filter out or reflect fluorescent light.

Refrigerated trucks deliver packaged milk to stores and homes. At one time, home delivery of milk was common. Today, most families buy their milk at a supermarket or other retail store.

History of the milk industry

No one knows when people first used animal milk for food. However, the people of ancient Babylon, Egypt, and India raised dairy cattle as early as 4000 B.C. At that time, the family cow was the chief source of milk. A family used as much milk as it needed and traded or sold the rest to neighbors. This practice is still common in some parts of the world.

In the United States, the family cow was especially common during colonial times. But by 1850, many U.S. farmers had begun to own several dairy cows and to supply milk to people living nearby. With the growth of cities, local laws prohibited keeping cows within city limits. Farmers outside the cities then began to increase the size of their herds and to establish dairy businesses.

As the dairy industry grew, several cities passed laws to control the sale of milk. Some laws made it illegal to add water to milk or to remove cream from it. Boston passed the first such law in 1856. But no early laws set health standards for milk. Many dairies added chemical preservatives to milk. But after some of these chemicals were found to be harmful, laws were passed that prohibited their use. Gradually, cities and states began supervising the industry to protect the public health.

Several inventions and new processes helped speed the growth of the milk industry. In 1856, an American inventor named Gail Borden patented the first successful milk-condensing process. About 1885, dairies began using glass jars and bottles, which workers filled by hand. The invention of a bottling machine in 1886 made filling the containers easier and faster.

In 1890, Stephen M. Babcock, an American agricultural chemist, developed a test to measure the fat content of milk. This test still plays a role in the measurement of fat content. In the 1890’s, dairy plants first introduced pasteurization, a process invented by the French scientist Louis Pasteur. Homogenizers gradually came into use after 1900.

In the mid-1980’s, researchers and certain dairy farmers in the United States began injecting a synthetic (laboratory-produced) substance called bovine somatotropin (BST) into test herds to increase the production of milk. This substance, also called bovine growth hormone, is almost identical to BST naturally produced by cows. Natural BST stimulates milk production in a cow that has given birth. Synthetic BST supplements the cow’s supply of the natural hormone. In 1985, the Food and Drug Administration (FDA) ruled that milk from the test herds was safe for human consumption. In 1993, the FDA approved the commercial use of synthetic BST. Today, about 30 percent of all milk cows in the United States belong to herds in which BST is used. Other areas of the world in which BST is used include Africa, Latin America, and the Middle East. BST has not been approved for use in Canada or in the countries of the European Union.