Mining is the process of extracting minerals or other valuable substances from the ground. Most substances that we get from the ground we obtain by mining. Mining provides iron for making automobiles, aluminum for manufacturing bicycles, and gravel for building highways. Mines supply salt for flavoring and preserving food, diamonds for use in jewelry, and silicon for making computer chips. Coal—which also comes from mines—can provide the energy to transform these raw materials into finished products.

Some valuable substances are found at the ground’s surface and can be mined cheaply. Other substances lie far beneath the surface and can be removed only by digging deep underground. Some mined substances are found in oceans, lakes, and rivers.

Many thousands of years ago, prehistoric people dug pits and tunnels to obtain minerals used for pigments and to make tools and weapons. They may have also mined other minerals, such as clay for making pottery. Sometime around 3500 B.C., people began mining tin and copper. They combined these metals to make bronze, a hard alloy (mixture of metals) for use in tools and weapons. During the same period, workers in Egypt quarried stone to construct large monuments, including pyramids. The ancient Romans recognized that mining metals could make a nation rich and powerful. They took over the mines of the countries they conquered, mining gold, silver, and lead. The Roman Empire split apart in the A.D. 400’s, and few mining advancements occurred over the next thousand years.

In the 1400’s, coal, iron, and other materials were mined in Europe, especially in Germany, Sweden, and France. Mining also developed in South America. The Inca and other South American peoples used metals to make tools, jewelry, and weapons. In the late 1500’s and early 1600’s, European miners began using gunpowder to blast through rock. The practice became widespread by the 1700’s.

Europeans began mining in what is now the United States during the early 1700’s. French explorers mined lead and zinc in southwest Missouri. Although Native Americans mined gold in the area long before Europeans arrived, European settlers first discovered gold in North Carolina in 1799. The discovery of gold at Sutter’s Mill in 1848 started the California gold rush. This gold rush led to the discovery of other useful minerals, such as copper, lead, and silver. About the same time, miners began mining large amounts of coal in Pennsylvania for use as fuel.

Geologists classify most substances obtained through mining as minerals. But that term generally excludes coal, petroleum, and natural gas, which formed from the remains of living things. Coal is mined in much the same way as minerals. This article discusses the mining of both minerals and coal. For information on recovery of oil and natural gas, see Petroleum and Gas.

Mineral deposits

Mines are built around mineral deposits, places where a given mineral is not too scarce or too difficult to recover. Such deposits vary in many respects. Some deposits lie at or near the surface, and others are far underground. Some minerals occur as a compact mass, and others are widely scattered. Minerals vary in hardness and in the ease with which useful material can be separated from the surrounding rocks or waste.

To be useful for mining, a deposit must contain a sufficient quantity of ore, rock or earth from which the mineral can be extracted at a profit. The profitability of mining the material in a deposit determines whether or not it is considered ore. Thus, the material in a deposit may become ore as the selling price of the mineral increases or as new mining processes reduce extraction costs.

Kinds of mining

Mining techniques vary based on the location and shape of a mineral deposit. Experts generally divide mining methods into three broad categories: (1) surface mining, (2) underground mining, and (3) hybrid mining. To reduce the costs of mining, many tasks once performed by human workers are now carried out by machines.

Surface mining methods

are used for deposits at or near the surface. They include (1) area mining, (2) open-pit mining, (3) placer mining, (4) dredging, and (5) quarrying. Surface mining disrupts the land and can greatly damage the natural environment. For this reason, surface-mining companies must plan for reclamation. Reclamation is a process in which the land is restored as closely as possible to its original state. In some cases, reclaimed land becomes more valuable than it was before mining. For example, lakes created in some mined areas provide opportunities for fishing and water sports.

Workers use machines called draglines to surface mine some loose deposits. These machines have a scoop, called a bucket, attached to a high boom (long beam) by a series of cables. The bucket is pulled back and forth along the mineral deposit to remove the overburden or waste material above the deposit.

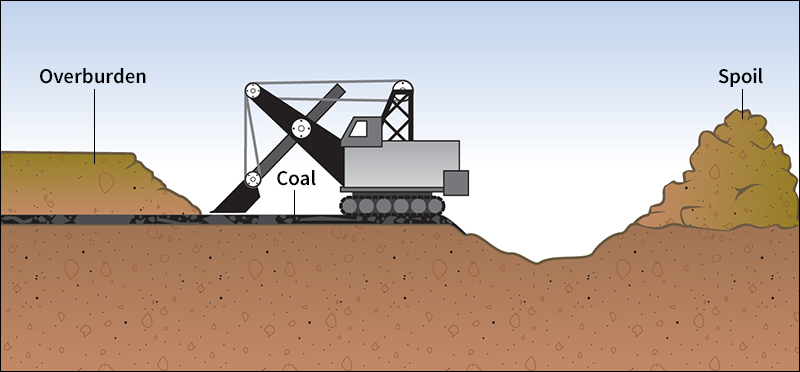

Area mining

is a method of obtaining coal and minerals that lie in flat deposits at or near the surface. Area mining on flat terrain is called strip mining or furrow mining. In this method, miners cut a long, narrow groove called a furrow and cast the waste into a long ridge parallel to the groove called a spoil pile. They break the ore up with machines or explosives and then use shovels or machines to load it into trucks or railroad cars. After removing all the ore from the first cut, the miners cut a new furrow, casting the spoil into the previous cut. Area mining around hills or mountains is called contour mining or collar mining.

In area mining, reclamation takes place as part of the mining cycle, with each mined area being reclaimed as a new area is mined. Only a certain amount of land can be mined before reclamation must start. To keep a continuous flow of ore from the mine, reclamation must keep pace with the mining. In the past, area mining developed a bad reputation because it caused great environmental destruction in and around the mines. This was especially true in mountainous areas, where area mining would destroy vegetation on mountainsides and lead to landslides. Mining engineers have worked to switch to less damaging methods of area mining.

Open-pit mining

is also used to recover ore lying close to the surface. First, the miners remove any rock or waste material covering the deposit. Then they use explosives to break up large masses of ore-bearing rock. The miners recover the ore in a series of horizontal layers called benches. Miners build a haul road connecting the benches up the sides of the pit. Trucks, trains, or conveyors haul the ore out of the pit. Open pit mines that produce crushed stone for buildings and roads are sometimes called rock quarries.

Open-pit mining uses equipment and techniques similar to those used in area mining, but varies in the timing of reclamation. In open-pit mining, reclamation typically does not occur until all the ore has been mined.

Placer mining

uses water to separate gold, platinum, tin, and other heavy minerals from gravel and sand deposits. The exact technique used depends on the abundance of the mineral and the availability of water.

On a small scale, workers may use panning to recover gold and other minerals from streams. In panning, the miner tips and swirls a shallow dish or pan filled with water and sand from the deposit. The water washes the sand away, leaving behind the heavier minerals.

On a larger scale, miners use a form of placer mining called sluicing. In this method, workers shovel mineral-bearing gravel and sand into the upper end of a slanting wooden trough called a riffle box. Water washes through the box, carrying away the gravel and sand while the heavier minerals settle in grooves on the bottom of the box. Rather than shoveling, workers may move mineral-bearing gravel and sand directly from the deposit into the riffle box using a large water nozzle called a giant. Miners call this process hydraulicking.

Dredging

is used where mineral-bearing sand and gravel layers are exceptionally thick. It requires a pond or lake on which a large, bargelike machine called a dredge can be floated. In one design, a chain of buckets is attached to a boom at the front of the dredge. The buckets dip into the water when the boom is lowered, scooping material from the bottom. Dredges dig up mineral-bearing sand and gravel and move it to a sluice box. After the valuable minerals are collected, a conveyor belt called a stacker dumps the sand and gravel back into the pond behind the dredge. By digging forward while disposing sand and gravel to the rear, the dredge moves ahead as the deposit is mined.

Quarrying

is a specialized mining method that produces stone pieces of a specific size or shape, called dimension stone. People use dimension stone to create decorative items, such as countertops and statues, or as structural elements in buildings. Workers quarry granite, limestone, and marble where high quality stone deposits are available. To free the blocks, miners typically saw, channel, or cut them on four sides and wedge them free from the larger rock. Then, miners hoist the blocks onto trucks or trains, which transport them to processing facilities. There, workers split them into smaller pieces, polishing and finishing some pieces for retail sale.

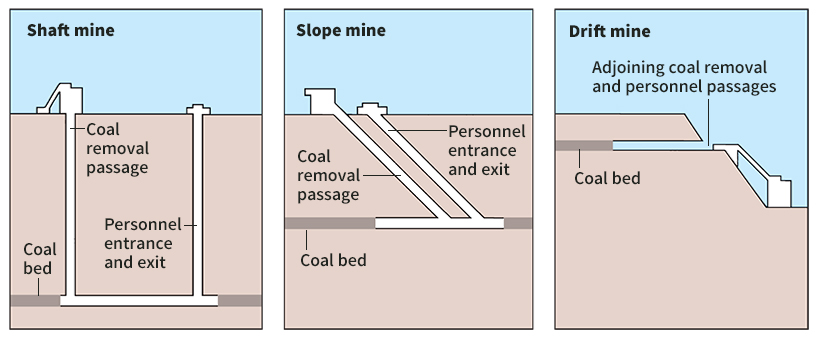

Underground mining methods

are used when the mineral deposit lies beneath the surface. Workers build three types of mines to access underground ore: (1) drift mines, (2) slope mines, and (3) shaft mines. Drift mines have horizontal (level) or nearly horizontal openings, and generally occur where ore outcrops (reaches all the way to the surface). Slope mines have a downward incline that leads to deeper deposits of ore. Shaft mines use completely vertical shafts to reach ore deeper than about 750 feet (230 meters) beneath the surface.

Miners generally divide underground mining techniques into three broad categories, depending on how the mine and the overlying material are supported to prevent collapse. These categories are: (1) self-supported mining (sometimes called unsupported mining), (2) supported mining, and (3) caving.

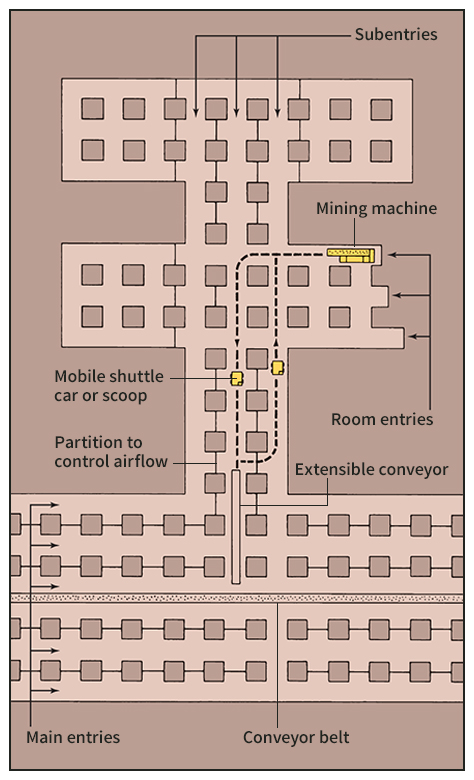

Self-supported mining

techniques rely on the ore itself to support workers and the overlying material. In a self-supported technique called room-and-pillar mining, workers excavate as much coal as possible from a horizontal deposit, leaving pillars of coal to support the rock above. This technique is used for flat deposits of coal. A similar technique called stope-and-pillar mining is used for thicker and more irregular horizontal deposits of non-coal minerals such as limestone, salt, and potash.

Another self-supported mining technique, called shrinkage stoping, progresses upward and uses blasted and broken ore as a work platform for further mining. Broken rock takes up more space than solid rock. Some of the rock must therefore be removed from the stope (excavated area) to provide space for further drilling and blasting.

Vertical crater retreat mining,

a patented self-supported mining method, uses specialized explosives to break the ore from the bottom upward. Workers can leave the broken ore in the stope to help maintain the stability of the stope walls.

Supported mining

typically uses the cut-and-fill technique. In this technique, miners remove horizontal “slices” of ore, starting at the bottom of the ore and advancing upward. After miners excavate a slice of ore, they fill the hole with waste material from ore-processing plants, often adding cement to increase the strength of the fill. This material supports the walls and provides a working platform from which to mine the next ore slice.

Caving

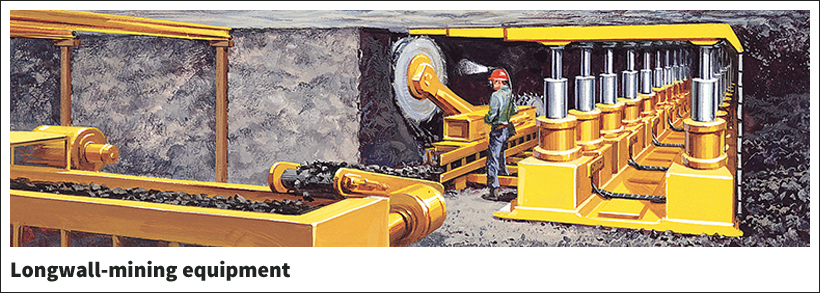

techniques allow parts of the mine to collapse or cave under controlled conditions. Longwall mining, a highly mechanized, extremely efficient caving technique, is used to remove coal from horizontal layers or seams. Miners use a machine to cut or break ore from a single long face called a longwall that can be up to 1200 feet (360 meters) long. Hydraulic roof supports hold up the roof above the miners. As the miners dig farther into the seam, the supports advance with them, and the roof behind the hydraulic supports collapses.

In block caving, miners divide the ore into large panels or blocks. They then undercut a panel with a horizontal slot. The rock and ore above the slot fractures and caves into the slot. Large machines remove the ore from the slot and transport it to vertical or inclined openings, where it is removed from the mine. Miners then proceed to the next panel and repeat the process.

Sublevel caving

is used to recover thin blocks of ore from steeply angled deposits. In sublevel caving, miners create stopes in the ore at various levels. The ore, broken in large vertical slices, falls to the bottom of the stopes. There, it is recovered for transport out of the mine.

Hybrid mining techniques

combine certain aspects of surface and underground mining. Highwall mining is a hybrid technique used in combination with the surface mining of coal. In this technique, miners use special push beams or push cars to drive a drilling device called a cutterhead into the wall of a previously mined furrow. The mined coal is transferred from the cutterhead for recovery. This creates a tunnel as wide as the cutterhead that can reach more than 1000 feet (300 meters) long. Experts consider highwall mining a hybrid technique because although the coal is mined from underground, no workers enter the underground area.

Pumping methods

involve the extraction of minerals in a liquid form. The waters of the ocean and of some lakes, including Great Salt Lake in Utah, contain huge amounts of dissolved minerals. Miners obtain these minerals by pumping the water into plants where it is treated. In such plants, pumps move large amounts of water through devices called precipitators that draw the minerals out of the water. Much of the magnesium used today is obtained by this method.

Workers sometimes use a pumping method known as solution mining to get salt from beds beneath the surface. Mine workers drill holes and circulate water underground to dissolve the salt and form a saltwater solution called brine. The brine is then pumped to the surface and taken to a factory. There, the water is evaporated, and the salt forms a solid again. Workers also use solution mining to extract copper and gold from low-quality ore. By dissolving the metals in a liquid, workers can separate them from the waste before removing them from solution.

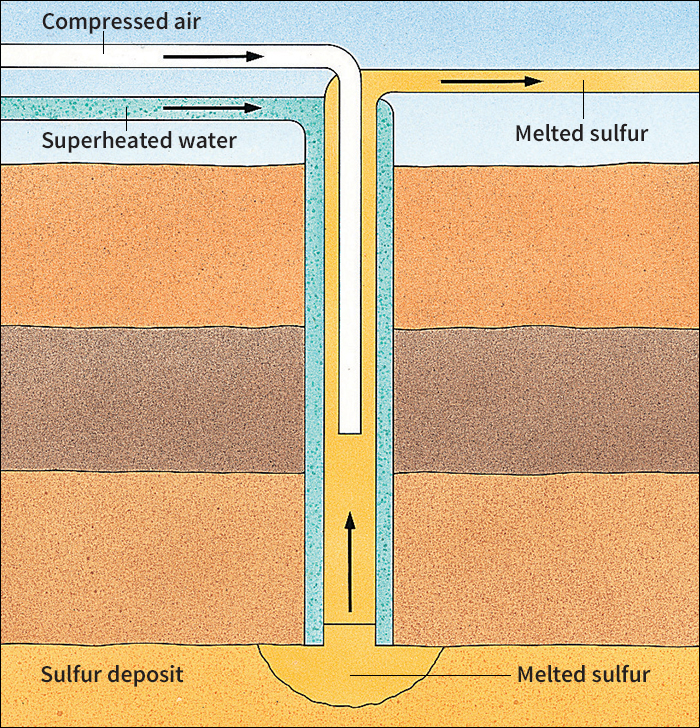

Miners often use the Frasch process, another pumping method, to mine sulfur, a mineral that melts easily. The miners drill holes in a buried sulfur bed and inject superheated water. The sulfur then melts and forms a liquid. The miners force the liquid sulfur to the surface by pumping compressed air into the holes. After the sulfur cools, it becomes a solid again and can be stored until needed.

Mining careers

The mining industry offers a wide variety of careers for professional, skilled, and semiskilled workers. Management in the mining industry consists mainly of business people and engineers. These people manage mines and processing facilities and direct the search for new mineral deposits. They also try to improve mining methods. Among the workers in mines are people skilled in operating and maintaining various kinds of specialized mining machinery. Other workers include mechanics, electricians, truck drivers, and laborers. Some people with mining experience serve as federal or state mine inspectors. They help enforce laws that promote miners’ health and safety. Others with mining experience may become involved in the sale of mining equipment, materials, and supplies.

Many universities and colleges offer training for specialized careers in mining industry engineering. A geological engineer or geologist guides the search for mineral deposits and estimates their value. A mining engineer designs the mine and directs the mining process. A metallurgist or metallurgical engineer directs refining of minerals. The mining industry also employs computer specialists, surveyors, chemists, and physicists.