Rugs and carpets are fabrics used as floor coverings. They add beauty, comfort, and warmth to a room, and they help absorb sound. Rugs and carpets also protect floors and provide a less slippery surface than a waxed or tiled floor. Most rugs and carpets are used in homes and other buildings, but some cover outdoor surfaces. Some rugs are used as decorative wallhangings.

The words rug and carpet are sometimes used interchangeably, but they refer to different types of floor coverings. A rug covers only part of the floor of a room and is not fastened down. A carpet covers an entire floor and is nailed, tacked, or glued down.

Most rugs and carpets are mass-produced and are made in a variety of textures and an almost unlimited number of colors and patterns. Some rugs are manufactured in standard sizes, such as 4 feet by 6 feet (1.2 meters by 1.8 meters) or 9 feet by 15 feet (2.7 meters by 5 meters). Other rugs are cut from large rolls of carpeting. Most carpeting is produced in 12-foot (3.7-meter) widths, but some is 15 feet (5 meters) wide. Other carpeting is cut into 9-, 12-, or 18-inch (23-, 30-, or 46-centimeter) squares called carpet tiles. Carpeting made on a loom or other machine more than 6 feet (1.8 meters) wide is called broadloom carpeting.

Rugs may also be made by hand. Handmade Oriental rugs are valued for their rareness and beauty.

The United States produces about 11/3 billion square yards (1 billion square meters) of rugs and carpets annually. Georgia is the leading state in the production of rugs and carpets, making more than 70 percent of these floor coverings. California ranks second in the production of rugs and carpets.

Materials used in rugs and carpets

Rugs and carpets have two main parts, the pile, or face, and the backing. The pile is the top surface, and the backing is the undersurface. Various manufactured or natural fibers are used in making both the pile and the backing. A few manufacturers produce pile with a blend of both manufactured and natural fibers.

The chief manufactured materials in pile fibers are nylon, olefin, and polyester. All these materials resist soiling and staining well. About 75 per cent of the rugs and carpets manufactured in the United States have nylon pile. Nylon fibers are durable and easy to dye. Olefin fibers make up the pile in about 14 per cent of the rugs and carpets produced in the United States. People use olefin floor coverings widely both indoors and outdoors because olefin resists moisture and fading. About 10 per cent of the rugs and carpets have polyester pile. Polyester fibers can absorb and hold brighter colors of dye than other manufactured fibers can. A small number of rugs and carpets have acrylic pile. Acrylic floor coverings are bulky but light in weight, and they resist fading. Tough nylon fibers make up the pile in artificial turf, a type of carpet used both indoors and outdoors for landscaping and playing surfaces.

Wool is the main natural fiber used in making pile. Until the 1940’s, nearly all rugs and carpets manufactured in the United States were made of wool. Today, wool is used for only about 1 per cent of the rugs and carpets made in the United States. Wool floor coverings are attractive, soft, and durable. Many people consider them the finest made. But most wool floor coverings cost more than those made from manufactured fibers.

The backing of most rugs and carpets is made of olefin or of jute, a natural fiber. Linen, polyester, and cotton are also used.

Kinds of rugs and carpets

Rugs and carpets are classified according to their pile textures. There are six main kinds of rugs and carpets: (1) level loop, (2) multilevel loop, (3) plush, (4) saxony, (5) frieze, and (6) cut and loop.

Level loop and multilevel loop floor coverings have a loop pile, which consists of loops of yarn. Plush, saxony, and frieze rugs and carpets have a cut pile. They are made with loops of yarn, but each loop is then cut in two, producing a surface of cut ends. The cut and loop type has a combination pile.

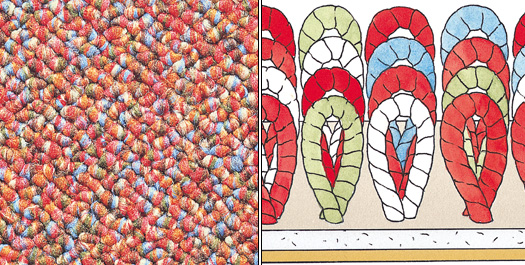

Level loop rugs and carpets

have a smooth, tight texture. All the loops of yarn that make up the pile have the same height.

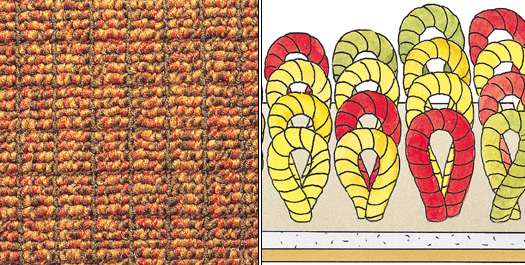

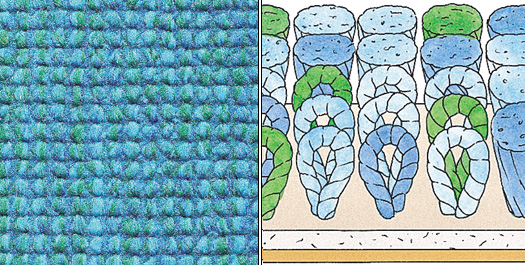

Multilevel loop rugs and carpets

have an uneven texture. The loops of their pile vary in height, giving the surface a patterned effect.

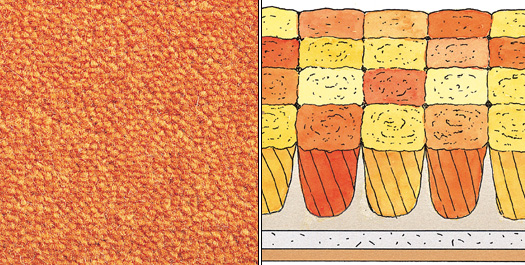

Plush rugs and carpets

are soft and have a luxurious appearance. The yarns of plush pile are short and loosely twisted. Plush pile provides a thick, level floor covering that is often desired in formal settings.

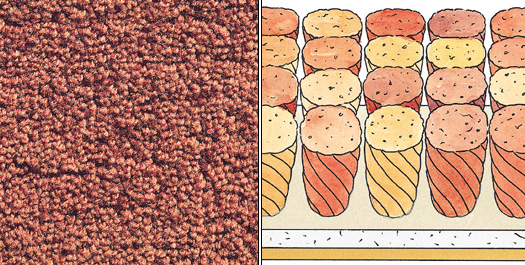

Saxony rugs and carpets

resemble the plush type. However, each yarn of a saxony floor covering stands erect and is clearly distinguishable. The ends of the yarn in plush pile tend to blend together.

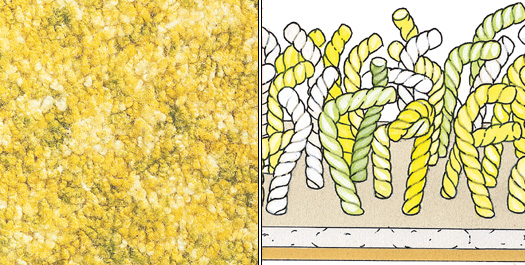

Frieze rugs and carpets

have a rougher texture than the other members of the cut pile group. The yarns of a frieze pile are tightly twisted, and they curl when inserted into the surface.

Cut and loop rugs and carpets

have yarns that vary in height. The longer yarns provide a cut pile. The shorter yarns are looped and may be hidden by the longer ones.

How rugs and carpets are made

More than 95 per cent of the rugs and carpets produced in the United States are made by a process called tufting. The rest are made by weaving or by other methods.

Tufting

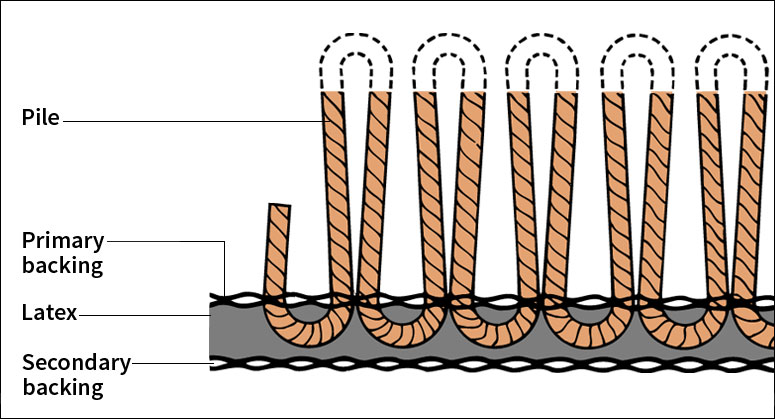

is the fastest and cheapest method of making rugs and carpets. Tufted floor coverings consist of clusters of pile yarns called tufts. Eyed needles insert the tufts into the backing.

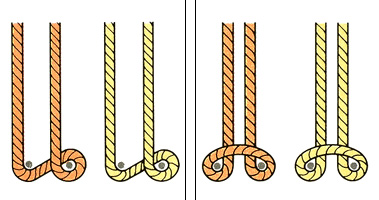

A tufting machine has hundreds of needles set in a row on a device called a needle bar. When the needle bar is lowered, each needle forces a loop of yarn through a layer of backing called primary backing. The loops form a row of tufts. As the needle bar is lifted, devices called loopers hold the tufts in place to form a looped pile. A cut pile can be made by attaching a knife blade to each looper.

A synthetic latex compound is applied to the primary backing to secure the tufts. A layer of backing called secondary backing may be added over the latex to provide extra durability. The secondary backing is made of jute or synthetic materials. Some tufted floor coverings have a layer of plastic foam instead of a secondary backing.

Weaving

was the chief method of manufacturing rugs and carpets in the United States until the development of tufting in the 1950’s. Woven floor coverings are made on looms by interlacing the pile yarns with backing yarns. Weaving the two kinds of yarns together holds the pile yarns securely in the backing.

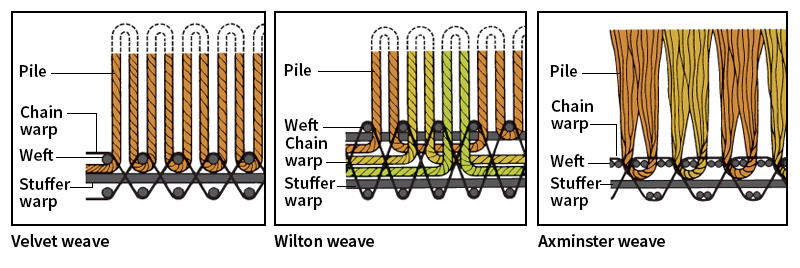

The pile of a woven rug or carpet is formed from one set of yarns. The backing is made from two sets. The pile yarns are woven into the backing in rows. During the weaving process, these yarns form loops over long, flat pieces of metal called wires that lie across the loom. This action creates a looped pile. A cut pile is produced by wires that have a knife blade at one end. In the backing, one set of yarns, called the weft, runs crosswise on the loom. Another set, called the warp, runs lengthwise. There are two kinds of warp yarns, chains and stuffers. Chain warps cross over and under the weft yarns to form the weave. Stuffer warps are extra yarns that run through the backing in order to give it greater bulk and strength.

There are three chief types of woven rugs and carpets: (1) velvet, (2) Wilton, and (3) Axminster. They differ in the way their pile yarns are woven into the backing, and each type is made on a different kind of loom. The backing for all three is made in basically the same way.

Velvet rugs and carpets

are made with the simplest type of weave. They are woven on looms similar to those used in making regular cloth. The majority of velvet floor coverings have a pile of one color, and a design cannot be woven into the surface. Most of the pile yarn is on the surface of the rug or carpet.

Wilton rugs and carpets

are woven on a loom that has a special device called a Jacquard mechanism. With this device, as many as six different colored yarns may be used in each row of the pile. A design, if desired, may be created on the surface. All the yarns run in rows along the backing, but only one yarn is raised to the surface at a time. Thus, a yarn of the desired color appears in the proper place in the design. The other yarns run under the surface, where they give strength and springiness to the backing.

Axminster rugs and carpets

may be produced in an unlimited number of colors and patterns. Most of the pile yarns of an Axminster floor covering appear on the surface. Each pile yarn is inserted into the carpet independently. As each yarn is inserted, it is interwoven with the backing yarns.

Other methods

include knitting, needle-punching, braiding, embroidering, and hooking.

Knitted rugs and carpets are produced on knitting machines by a process that is similar to hand knitting. The pile yarns and the backing yarns are knitted together. Needle-punched floor coverings are made from fibers that have been tangled together by means of barbed needles. This tangled mass is then compressed into thick, feltlike material that can be used both indoors and outdoors.

Braided floor coverings are manufactured from individual braids of yarn or fabric. The braids are sewn together and coiled into a circle, an oval, or some other shape. Embroidered floor coverings are created by stitching designs onto the backing. The designs form the pile. Hooked rugs are produced by punching yarns through the backing with a metal hook.

Oriental rugs

People who live in Asia have traditionally created beautiful handmade rugs. Authentic Oriental rugs have pile yarns that are hand-knotted onto a woven backing. These rugs are made in such countries as China, India, Iran, and Turkey.

Oriental rugs are valuable because they have intricate designs and take a long time to weave. The value of an Oriental rug depends in part on the type of material used to create the rug and on the size and closeness of the rug’s weave. Tightly woven Oriental rugs are more expensive because they require the most time to make and are the most durable. Age, condition, and color also contribute to a rug’s value.

An Oriental rug is not as perfect as a mass-produced rug. The size and shape of an Oriental rug may not be exact, and the color in various areas of the rug may differ slightly.

Oriental rugs are woven on simple looms. A small rug may be woven by one person, but most large Oriental rugs are made by several weavers. First, the rug makers knot a row of pile yarns to the warp yarns. Next, they weave one or more weft yarns through the warp. The knots and weft yarns are then packed down tightly on the previously woven rows with a comblike device. The knotting process is then repeated. Trimming the ends of the knotted pile yarns creates the rug’s even surface.

Almost every Oriental rug is made with one of two types of knots. A Persian, or Sehna, knot twists the pile and warp yarns together. A Turkish, or Ghiordes, knot ties the yarns. Most Oriental rugs have from 50 to 500 knots per square inch (8 to 78 knots per square centimeter).

Most Oriental rugs have wool pile yarns, but some have pile yarns of silk. The warp and weft yarns of most Oriental rugs are made of cotton or wool. Hemp, jute, and silk are less commonly used.

The chief colors in most Oriental rugs are blue, brown, red, and white. Most of the yarns are treated with chemical dyes to obtain various shades of these colors. Before these chemical dyes were developed, the yarns were colored with natural dyes made from plants and minerals. Today, a few rug makers still use natural dyes.

Oriental rugs called prayer rugs are made in Islamic regions of Asia. The design of a prayer rug includes a pointed or arch-shaped pattern representing the prayer niche of the mosque. Muslims face Mecca, their holy city, as they kneel in prayer, and the rug is placed with the design pointed toward it.

There are six chief types of Oriental rugs. They are (1) Caucasian rugs, (2) Chinese rugs, (3) Indian rugs, (4) Persian rugs, (5) Turkish rugs, and (6) Turkoman rugs. Oriental rugs are named for regions where they are made.

Caucasian rugs

come from the Caucasus Mountains between Europe and Asia. These rugs have geometric designs woven in bold reds, blues, yellows, and other colors.

Chinese rugs

have designs that feature philosophical and religious symbols of China. The designs are woven into backgrounds originally of blue, red, and yellow. Time may have changed the reds in some older rugs to lighter colors.

Indian rugs

resemble Persian rugs in color and pattern. Many of the designs feature plants and animals.

Persian rugs

are made in Iran (formerly Persia). Their graceful patterns feature flowers, leaves, and birds. Some Persian rugs feature animal combat scenes. Persian rugs have soft, blended colors.

Turkish rugs

are known for their rectangular patterns and their floral designs arranged in rows. Most of these rugs have large areas of solid colors.

Turkoman rugs

come from Turkestan, a region of central Asia. They are woven primarily in reddish tones and have simple geometric designs.

History

Some prehistoric people may have used animal skins as floor coverings in their caves or huts. After people learned to weave, they made floor mats from grasses and other plant material.

No one knows when rug making began. The earliest known fabric made with pile is called the Pazyryk rug. It was made around the 400’s B.C. and was discovered in a tomb in southern Siberia.

Crusaders who traveled to the Middle East during the A.D. 1100’s and 1200’s probably brought rugs back to Europe. In the 1200’s, Spain became the first European country to produce rugs. England started making pile rugs in the 1500’s.

During the 1600’s, France began to make a style of rug called the Savonnerie, which had a deep pile. During the 1700’s, England was the center of the European rug and carpet industry. An English inventor named Edmund Cartwright developed the power loom during the 1780’s.

In North America, the most common rugs during colonial times were braided rugs, hooked rugs, and rag rugs, which were made from scraps of cloth. The first U.S. carpet mill was set up in 1791 in Philadelphia.

The Jacquard mechanism was invented about 1800 by Joseph M. Jacquard, a French weaver. Erastus B. Bigelow, a Massachusetts inventor, perfected a power loom for making carpets in the early 1840’s. A power loom for producing Axminster carpets was patented in 1856.

The tufting machine for carpeting was introduced in the early 1950’s. By the mid-1950’s, more tufted rugs and carpets than woven ones were being produced in the United States.