Steam engine is any engine that is operated by the energy of expanding steam. The steam may be used to power an engine by spinning a turbine or by pushing pistons. Huge turbines drive electric generators and giant ships. Piston steam engines power large pile drivers. In some countries, locomotives with piston steam engines are still used to pull railroad trains. In the United States, diesel locomotives pull most trains.

The development of the steam engine in the 1700’s made modern industry possible. Until then, people had to depend on the power of their own muscles or on animal, wind, and water power. One steam engine could do the work of many horses. It could supply the power needed to run all the machines in a factory. A steam locomotive could haul heavy loads of freight great distances in a single day. Steamships provided safe, fast, dependable water transportation.

How steam engines work

A steam engine uses steam to change heat energy into rotary or reciprocating (back-and-forth) motion. Most steam engines have a furnace in which coal, oil, or some other fuel is burned to produce heat energy. In atomic power plants, a nuclear reactor supplies the heat energy (see Nuclear energy (Steam production) ).

Every steam engine has a boiler. The heat energy produced inside the furnace or reactor changes water into steam inside the boiler. The steam expands, taking up many times the space of the original water. This energy of expansion can be used in two ways: (1) to spin a turbine, or (2) to push a piston back and forth.

Steam turbines

produce a rotary motion. A steam turbine has many sets of bladed wheels mounted on a long shaft. The steam enters at one end and spins the bladed wheels as it rushes past them. Steam turbines, which are more efficient than reciprocating steam engines, are used to turn electric generators and ship propellers. See Turbine (Steam turbines) .

Reciprocating steam engines

have pistons that slide back and forth in cylinders. Various valves allow the steam to enter a cylinder and drive a piston first in one direction and then the other before they exhaust the used steam. Steam hammers that drive piles and forge metal require reciprocating motion (see Forging ; Steam hammer ). A locomotive, however, requires rotary motion to turn its wheels. This motion is achieved by attaching a crankshaft to the pistons. In some reciprocating steam engines, called compound engines, the steam may flow through two, three, or four cylinders and operate the same number of pistons.

History

Hero, a scientist who lived in Alexandria, Egypt, described the first known steam engine about A.D. 60. The device consisted of a small, hollow globe mounted on a pipe running to a steam kettle. Two L-shaped pipes were fastened to opposite sides of the globe. When steam rushed out of the two L-shaped pipes, it caused the globe to whirl. But this device performed no useful work. Hundreds of years passed before the first successful steam engines were developed in the 1600’s.

The first steam engines

operated on the ability of steam to condense back into a liquid rather than on its ability to expand. When steam condenses, the liquid takes less space than the steam. If this condensation takes place in a sealed vessel (container), it creates within this vessel a partial vacuum (a pressure much lower than that of the surrounding atmosphere). Liquids and gases tend to flow from regions of higher pressure to regions of lower pressure, so when a vessel containing a partial vacuum is opened, the vacuum exerts a sucking action on whatever is on the other side of the opening. Thus, the partial vacuum and the surrounding atmosphere act together to perform work.

In 1698, Thomas Savery, an Englishman, patented the first practical steam engine, a pump to drain water from mines. Savery’s pump had no moving parts other than valves operated by hand. These were turned to let steam enter a sealed vessel. Cold water was poured on the vessel to chill it and condense the steam. Then a valve was opened so the vacuum in the vessel could suck water up a pipe.

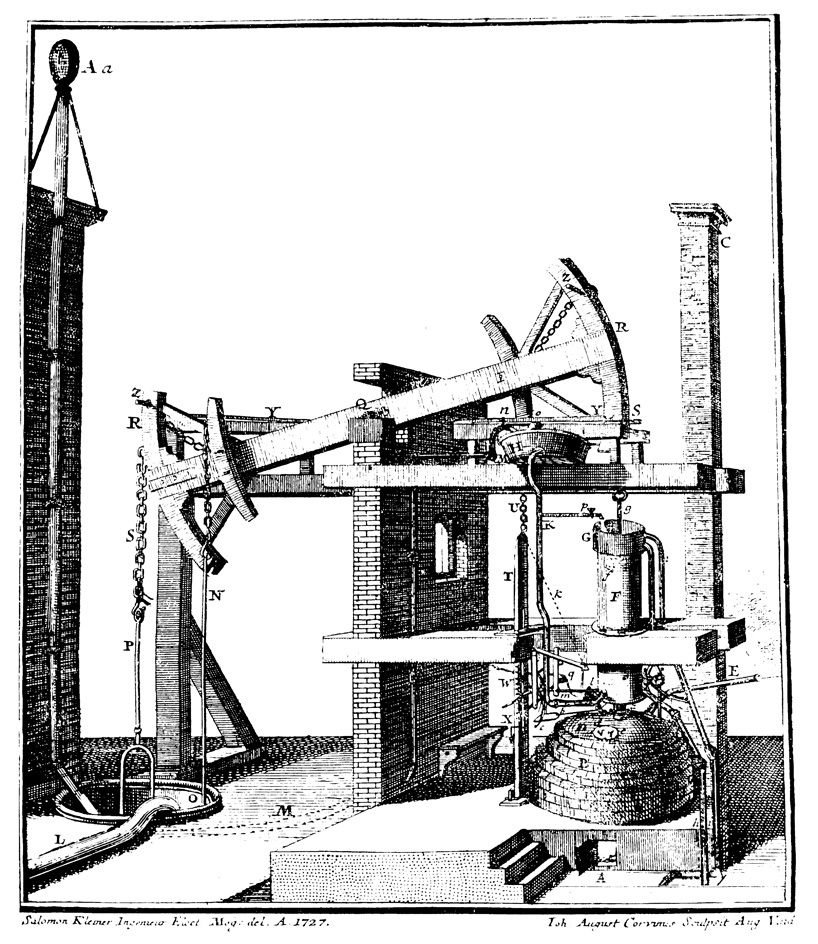

In 1712, Thomas Newcomen, an English tool seller, invented anther steam-engine pump for mines. Newcomen’s engine had a large horizontal beam balanced in the middle like a seesaw. A piston that fitted into a cylinder hung from one end of the beam. When steam was let into the cylinder, it forced the piston up, lowering the other end of the beam. Cold water was then sprayed into the cylinder, the steam condensed, and the vacuum sucked the piston down again. This raised the other end of the horizontal beam, which was attached to the piston of a pump in a mine.

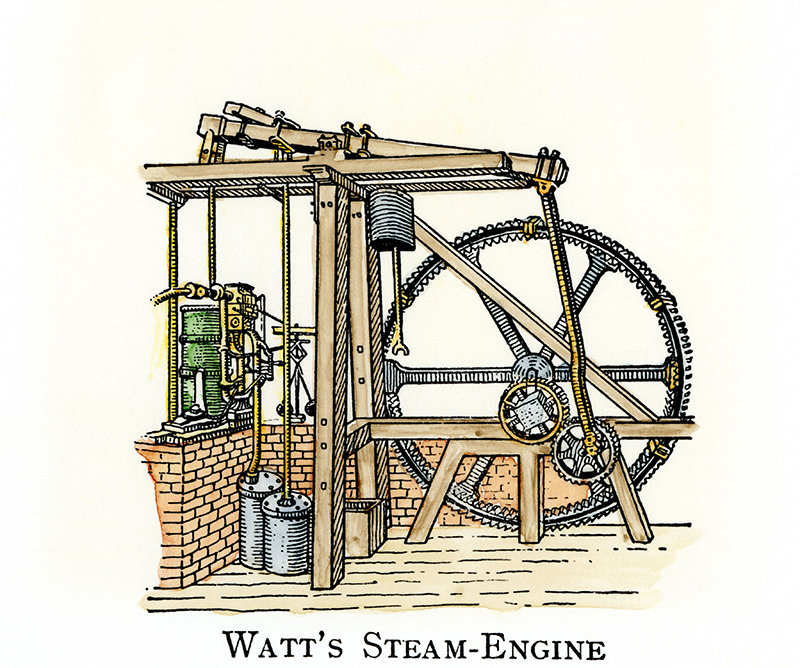

Watt’s engine.

When James Watt began his experiments in 1763, the Newcomen engine was the best known. It set Watt to thinking because it used an enormous quantity of steam and therefore a large amount of fuel. Watt saw that the alternate heating and cooling of the cylinder wasted much heat. He invented an engine in which the condenser and the cylinder were separate. The cylinder remained hot. This arrangement saved three-fourths of the fuel cost because little steam was lost through condensation by entering a cold cylinder.

Watt took out his first patent on a steam engine in 1769 and continued to improve his engines. Perhaps his most important improvement was the use of the double-action principle. In engines based on this principle, the steam is used first on one side of the piston, then on the other. Watt also learned to shut off the steam when the cylinder was only partly filled. The steam already in the cylinder completed the piston’s stroke. Many people believe Watt invented the steam engine. But he only improved previous designs. He made it practical to use condensing engines for work other than pumping.

Modern steam engines.

The main improvement in the years after Newcomen and Watt was the development of engines that could use high-pressure steam. Watt never experimented in the use of high-pressure steam because he feared an explosion. The pressures in his engines were not much greater than normal atmospheric pressure, or about 15 pounds per square inch (p. s. i.), or 103 kilopascals. Then, in the late 1700’s and early 1800’s, Richard Trevithick of England designed and built the first high-pressure steam engines. One of his first engines operated under 30 p. s. i. (207 kilopascals) of pressure. By 1815, Oliver Evans, an American, had built an engine that used 200 p. s. i. (1,379 kilopascals) of pressure. Today, many engines use steam under a pressure of more than 1,000 p. s. i. (6,895 kilopascals).

Other improvements made in steam engines included the development of the compound engine, and the use of superheated steam. In superheating, the temperature of the steam is raised above the boiling point at the engine’s pressure. This process helps keep the incoming steam from condensing because superheated steam does not cool as quickly as ordinary steam. In the late 1800’s, the invention of steam turbines marked another big improvement in steam engines. During the early 1900’s, steam turbines replaced piston steam engines in electrical generating stations.