Tobacco is a plant whose leaves are used to make smoking tobacco—used in cigarettes, cigars, and pipes—as well as chewing tobacco and snuff. The tobacco plant produces a compound called nicotine in its root system. The plant then transfers the nicotine to its leaves. When absorbed by the body, nicotine stimulates the heart and other organs along with the central nervous system.

Although the stimulating effects of nicotine make tobacco use pleasurable, they also make it addictive. Physicians have also shown that the nicotine in cigarettes contributes to heart attacks. Studies link other substances in cigarette smoke to cancers, including lung cancer. Medical studies have associated the use of smokeless tobacco products, such as snuff, with mouth cancers. Cigar use has been linked to mouth and throat cancers.

This article deals primarily with the farming of tobacco and manufacture of tobacco products. For more information on the dangers of tobacco use, see Smoking.

The tobacco plant

In the wild, tobacco grows as a tropical perennial, a plant that lives for more than two years or growing seasons. However, farmers cultivate tobacco as an annual crop, harvesting the plant after only one season. Tobacco grows best in warm climates with long growing seasons. The plant reaches a height of 4 to 6 feet (1.2 to 1.8 meters). It produces about 10 to 30 leaves, depending on the kind of tobacco. Farmers top (cut off the upper part of) the plant when it begins to produce flowers. Topping helps the remaining leaves to grow larger and heavier. The leaves measure from 24 to 30 inches (60 to 75 centimeters) long and 15 to 18 inches (38 to 46 centimeters) wide. The tobacco plant ranges from light to dark green in color. A mature plant can produce hundreds of thousands of seeds—enough to plant dozens of acres (tens of hectares) of tobacco.

Kinds of tobacco

Farmers generally classify tobacco according to the method used to cure (dry) the leaves. The major groups include: (1) air-cured tobacco, (2) fire-cured tobacco, (3) flue-cured tobacco, and (4) sun-cured tobacco. A fifth major group, cigar leaf tobacco, is air cured but usually classified separately according to its use.

Air-cured tobacco

consists of two varieties, light air-cured and dark air-cured. Most cigarettes contain the two major types of light air-cured tobacco, burley and Maryland. Burley tobacco accounts for about one-fifth of tobacco production in the United States. Argentina, Brazil, and Malawi also grow significant amounts of burley tobacco. Manufacturers use dark air-cured tobacco primarily for chewing tobacco and snuff.

Fire-cured tobacco

has a distinctive smoky aroma and flavor. Manufacturers use it to make smoking tobacco, chewing tobacco, snuff, and strong-tasting cigars.

Flue-cured tobacco,

also called bright tobacco, turns yellow to reddish-orange in color during the curing process. It accounts for about three-fourths of the tobacco produced in the United States. Brazil, China, the United States, and Zimbabwe are among the world leaders in flue-cured tobacco production. Manufacturers use most flue-cured tobacco in cigarettes.

Sun-cured tobacco

makes up only a small amount of the world’s tobacco crop. Oriental tobacco, the best-known variety, has small, compact leaves that produce a strong aroma when smoked. It grows best in dry climates with little rainfall and poor quality soils. Bulgaria, Greece, North Macedonia, and Turkey are leading growers of Oriental tobacco. Pure Turkish cigarettes consist of 100 percent unblended Oriental tobacco. Some smoking tobacco, snuff, and chewing tobacco contain blended Oriental tobacco.

Cigar leaf tobacco

includes three types: (1) cigar filler tobacco, (2) cigar binder tobacco, and (3) cigar wrapper tobacco. Cigar filler has a sweet flavor and burns evenly. Manufacturers use it in the body of cigars. Cigar binder tobacco holds the filler tobacco together in expensive hand-rolled cigars. Cigar wrapper tobacco covers the outside of cigars. It must have smooth, thin, high-quality leaves that appear uniform in color. Less expensive cigars have reconstituted tobacco sheets for their binder and, in some brands, for their wrapper. These sheets are manufactured from small tobacco leaf particles and stems. Brazil, Cameroon, Cuba, the Dominican Republic, Honduras, Indonesia, Mexico, and Nicaragua grow much of the world’s cigar leaf tobacco.

Growing tobacco

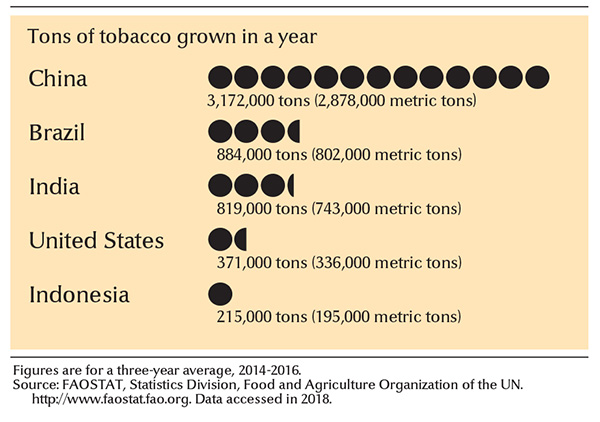

Farmers in many countries grow tobacco. China leads the world in both production and consumption. Other major tobacco producers include Brazil, India, and the United States. North Carolina and Kentucky lead the United States in tobacco production. Ontario produces most of Canada’s tobacco crop.

Planting and cultivation.

The soil and climate conditions that favor tobacco growth vary depending on the kind of tobacco. Most tobacco grows best in warm climates with moderate and regular rainfall. Tobacco also thrives in loose, well-drained soil, and generally requires a growing season with at least 120 frost-free days.

Because tobacco seeds are small, farmers first sow them in sheltered nurseries, usually inside greenhouses. The seedlings typically grow there for 40 to 60 days or until the stems measure about 4 to 6 inches (10 to 15 centimeters) tall. Farmers then transplant the seedlings into the field.

Farmers cultivate the soil in the field several times to keep it loose and to eliminate weeds. The last cultivation occurs after the plants grow 18 to 24 inches (45 to 60 centimeters) high. The farmer tops the plant about 50 to 70 days after transplanting.

Diseases and pests.

Various diseases attack the roots, stalks, and leaves of tobacco plants. Common root diseases include black shank and bacterial wilt, also known as Granville wilt. A serious viral disease, tomato spotted wilt, affects the plant’s stalk and leaves. Tobacco leaf diseases include blue mold and brown spot. Nematodes, as well as budworms, flea beetles, grasshoppers, and other insects, also damage tobacco plants.

Methods for controlling diseases and pests vary. The most effective practices combine the use of pesticides, the breeding of disease-resistant tobacco varieties, and crop rotation, alternating the crops grown in a given field each year.

Harvesting.

Farmers typically harvest tobacco from 70 to 120 days after transplanting. They use two harvesting methods, priming and stalk-cutting.

Priming involves picking the individual tobacco leaves as they ripen. Most growers now use priming machines to pick the leaves, though they were once picked by hand. Tobacco farmers use the priming method to harvest cigar wrapper, flue-cured, and Oriental tobaccos.

Stalk-cutting consists of cutting the entire plant with a hatchetlike tool. Farmers then place the stalks on sticks and leave them in the field for a day or two to wilt. The tobacco then cures in barns, after which workers remove the leaves from the stalk. Farmers harvest air-cured and fire-cured tobacco in this way.

Curing tobacco

Curing involves a careful and controlled drying of the harvested tobacco leaves to preserve them. This process also promotes chemical changes in tobacco that improve its flavor and aroma. Farmers use four methods to cure tobacco: (1) air curing, (2) fire curing, (3) flue curing, and (4) sun curing. Most curing takes place in curing barns built specifically for use with a particular method.

Air curing

relies on natural weather conditions to dry tobacco. A region’s air temperature and humidity play important roles in successful air curing. Farmers can exert only a limited control over these factors, primarily by opening and closing ventilators in the curing barn. Air curing takes from about four to eight weeks.

Fire curing

uses the smoke from low-burning wood fires to dry the tobacco leaves. The farmer builds small fires on the floor of the curing barn and regulates the heat, humidity, and ventilation in the barn to avoid scalding the leaves. The smoke gives fire-cured tobacco its distinctive taste and aroma. This method may take from a few days to more than one month.

Flue curing

dries tobacco with heat, originally provided via flues (pipes) that extend from a furnace into the curing barn. The current method involves placing racks of tobacco in metal barns and forcing heated air through the leaves. Farmers gradually raise the temperature until the leaves and stems dry completely. This method takes about six to seven days.

Sun curing

is similar to air curing but the leaves are dried by exposure to the sun. It takes two to four weeks.

Marketing tobacco

Farmers produce and sell most of the world’s tobacco under contract with a tobacco product manufacturer or a dealer called a leaf merchant. Prior to planting, the grower and buyer often agree on the quantity of tobacco that the buyer will purchase. The buyer specifies a price for the tobacco based on the quality of the leaves.

Manufacturing tobacco

Freshly cured tobacco has a sharp aroma and bitter taste. Manufacturers therefore store most tobacco to allow it to age before using it in tobacco products.

Aging tobacco.

Prior to storage, most tobacco goes through a redrying process, during which the manufacturer completely dries and cools the leaves. The manufacturer then restores some water evenly throughout the leaves to prevent them from breaking.

Next, the manufacturer stores the tobacco in large cardboard boxes or in hogsheads (barrellike containers) to age for about two years. While aging, the tobacco darkens and undergoes chemical changes that give it a milder flavor and aroma.

Manufacturers use a somewhat different procedure to age cigar leaf tobacco, which does not require redrying. Workers stack the tobacco leaves into large piles and place the piles in a warm environment. They turn the leaves periodically so that all leaves spend some time at the top, middle, and bottom of the pile. This turning process helps age the leaves at an equal rate.

Blending tobacco

helps manufacturers to produce tobacco products with the desired flavor and other qualities. Cigarettes contain blends of burley, Maryland, flue-cured, and imported Oriental tobaccos. Manufacturers can also add such flavorings as licorice, menthol, and sugar to the blended tobacco. They often add a chemical called glycerine to preserve moisture.

Making tobacco products.

Various machines handle the entire process of making and packaging cigarettes. Some machines can produce up to 16,000 cigarettes each minute.

Cigars consist of about 85 percent cigar filler, 10 percent cigar binder, and 5 percent cigar wrapper tobaccos. Machines make most cigars, but workers in Central American and Caribbean countries roll the more expensive brands by hand.

Chewing tobacco and snuff products typically consist of dark air-cured and fire-cured tobacco. Other ingredients, such as sugar and licorice, are added to many kinds of chewing tobacco. Snuff is typically packaged as a moist powder, rather than the dry powder used in the past. Manufacturers produce moist snuffs with a number of flavors, including wintergreen and cherry.

History

The word tobacco probably comes from a hollow Y-shaped tube, called a tobaca or tobaga, that American Indians used to inhale tobacco smoke and tobacco powder. Many different cultures throughout the Western hemisphere cultivated and used tobacco thousands of years before the Italian navigator Christopher Columbus sailed to the New World in 1492.

Many Europeans began using tobacco soon after arriving in the New World. In the first half of the 1500’s, Portugal established colonies for tobacco production in Brazil, and Spain established tobacco colonies in the Caribbean region. Explorers probably brought tobacco seeds back to Portugal and Spain in the mid-1500’s. Farmers there began to grow tobacco for domestic use. About 1560, the French ambassador to Portugal, Jean Nicot, introduced tobacco to France. Tobacco got its botanical name, Nicotiana, from him. By about 1600, tobacco had spread to much of Europe, Asia, and Africa.

In 1612, John Rolfe, an English colonist in Virginia, introduced a type of tobacco from the Caribbean. Rolfe’s tobacco was milder than the harsh-tasting native Virginia plant. The Virginia soil and climate proved excellent for growing tobacco, and Rolfe soon began sending commercial shipments to England. Demand grew quickly, and tobacco production expanded into neighboring states, particularly Kentucky, Maryland, North Carolina, and Tennessee.

Spaniards and other Europeans began smoking hand-rolled cigarettes in the 1600’s, but few people in the United States used them until the late 1800’s. Cigarette smoking became increasingly popular after an American inventor, James A. Bonsack, patented the first cigarette-rolling machine in the early 1880’s.

The use of tobacco has been the subject of controversy almost since its introduction to Europe. In the 1500’s, many political and religious figures argued against tobacco use on moral grounds. Some European physicians declared that tobacco should be reserved for medicinal purposes. In 1604, King James I of England wrote A Counterblaste to Tobacco, a pamphlet intended to shame the English into giving up social tobacco use.

In the 1950’s and 1960’s, scientists found that smoking tobacco products, especially cigarettes, could cause lung cancer, heart disease, and other illnesses. Since then, smoking has become prohibited in many public places. In 1996, the Liggett Group in the United States became the first tobacco company to pay money for harm to smokers in response to a lawsuit. For more details on settlements made by tobacco companies in response to lawsuits, see Smoking (Smoking regulations).

Australia, Canada, the United Kingdom, the United States, and many other countries require manufacturers to include a health warning on cigarette packages and cartons. Many countries ban some or all forms of tobacco advertising. Some national, state, and local governments prohibit smoking in nearly all public places. Taxes on tobacco products provide a major source of revenue for many governments.