Air conditioning controls the temperature, moisture, cleanliness, and movement of indoor air. It cools the air when the weather is hot. It warms the air when the weather is cold. Comfort depends partly on humidity, and air conditioning removes moisture from the air or adds it as needed. Removing dirt and dust from air makes the air more healthful. By controlling air movement, air conditioning brings fresh air into a room and pushes out stale air. In all these ways, air conditioning provides air that makes people comfortable at work, at play, and while sleeping.

How we use air conditioning

For comfort.

When the weather is hot, most people enjoy eating in cool, air-conditioned restaurants. They sleep better in air-conditioned bedrooms. Airplanes, trains, ships, buses, and automobiles that are air conditioned make traveling more pleasant. Air conditioning helps keep homes clean by taking dirt from the air. It often relieves the discomfort of hay-fever victims, because it removes pollen from the air. Air-conditioned hospitals protect the health and improve the comfort of patients and hospital staffs.

During cold weather, air conditioning performs much the same services. It supplies clean, moist air that is warmed to the most comfortable temperatures for working and sleeping.

In business and industry,

air conditioning improves the efficiency of workers. Employees stay more alert and become less tired in air-conditioned offices and factories. They make fewer mistakes and have fewer accidents. Air conditioning also protects workers against high temperatures and harmful dust, smoke, and fumes. In stores and shops, air conditioning keeps merchandise clean. It also increases sales, because people like to shop in comfort.

Several industries, such as the electronics industry, work with delicate parts and therefore require air-conditioned clean rooms, which are free of dust or germs. Companies in these industries make or assemble equipment in such rooms because the tiniest speck of dust could prevent the equipment from working properly.

Large computers become warm when in use and are sensitive to dust. A computer may break down unless air conditioning removes this heat and keeps the surrounding air clean.

Metals and other materials expand as the temperature rises, and contract as the temperature drops. For this reason, air conditioning is used to control the temperature in factories that manufacture tools or parts for instruments, watches, cameras, and other precision products. Changes in temperature would change the size of such products.

Many nonmetallic materials, including textiles, paper, and tobacco, absorb moisture from the air. Too much moisture may make these materials stretch out of shape. Too little moisture in the air makes these materials dry and brittle.

Almost all textile mills use air conditioning to control moisture so they can produce strong, uniform threads and fabrics. Some fibers, such as nylon and rayon, could not be made and woven into cloth without air conditioning. Even the sewing machines that mass-produce nylon stockings require proper temperature control. The needles of these machines are so small, and operate in such tiny spaces, that sudden temperature changes could cause them to jam and break.

Paper stretches in wet weather, and becomes brittle in dry weather. Air conditioning helps control moisture in printing plants so the paper will remain flexible and stay the same size. This makes possible high-speed printing of newspapers, magazines, and books throughout the year.

In bakeries, air conditioning controls the rising of bread dough. It also keeps flour from molding. Bread that is cooled in air-conditioned rooms has crack-free crusts.

In drug and chemical plants, air conditioning not only provides clean air but also removes germs from air. Air conditioning keeps moisture at the proper level so that powders, salts, and other chemical substances stay dry.

Air-conditioning systems in commercial buildings are being used increasingly for smoke control during fires. By controlling the airflow, the systems provide smoke-free areas for evacuation and fire-fighter access.

How air conditioners work

There are three main kinds of air-conditioning systems. Summer air conditioning cleans, cools, and removes moisture from air. Winter air conditioning cleans, heats, and adds moisture to air. Year-round air conditioning cleans and controls the temperature and moisture content of air throughout the year. All air-conditioning systems have some way of blowing, or circulating, the conditioned air through rooms.

Cleaning the air

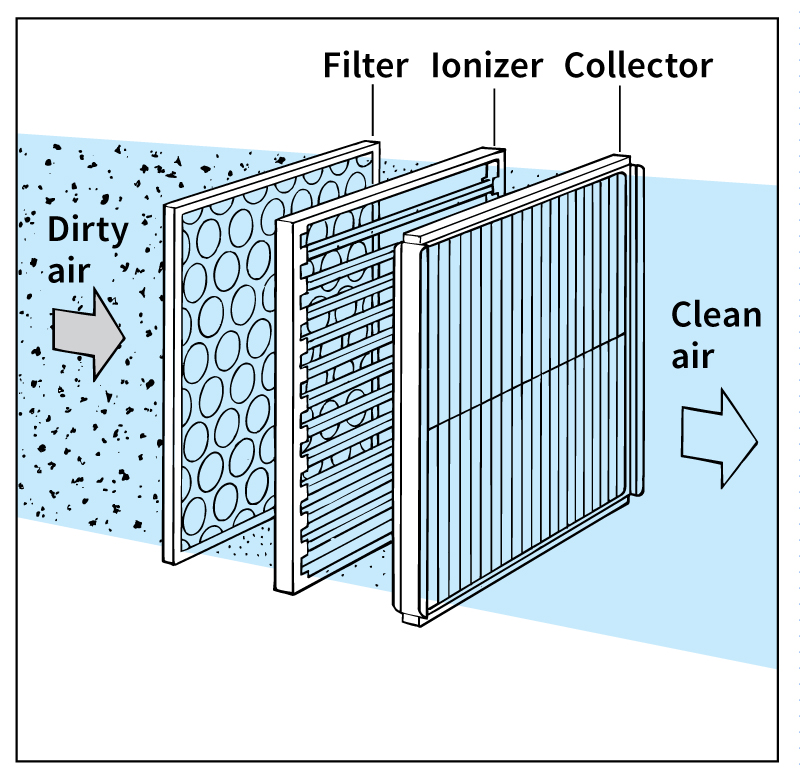

can be done in several ways. Some air conditioners force the air through filters. The filters usually consist of closely packed fiberglass wool or metal fibers that have been coated with a sticky oil or some other type of adhesive (see Fiberglass). As the air passes through, the dirt, dust, and soot in the air stick to the fibers. Air can also be cleaned by blowing it through sprays of water called air washers. A central air conditioner that uses this method has a row of nozzles that squirt a fine mist of water into the air. The water rinses out the dirt. Central air conditioners may also be equipped with electrostatic filters, or electrostatic precipitators. These devices put an electric charge on the particles of dirt in the air. Oppositely charged collector plates attract the charged particles out of the air (see Air cleaner). Some central air conditioners force the air through porous pieces of carbon, which absorb odors.

Drug firms and hospitals require extremely pure air. They usually have air conditioners equipped with special filters. These filters remove all dirt particles down to a size of 1/85,000 inch (0.0003 millimeter). Air conditioners may also have special lamps that kill germs in the air with ultraviolet rays (see Ultraviolet rays).

Controlling the temperature.

After an air conditioner cleans the air, it must cool it in summer and heat it in winter. Most people feel comfortable when the temperature of the air is between 68 °F (20 °C) and 75 °F (24 °C) in the winter and between 73 °F (23 °C) and 79 °F (26 °C) in the summer.

To cool the air, some air conditioners blow it through sprays of cold water. The same sprays that clean the air may also cool it. Most air conditioners blow the air over coils (large groups of tubes) that are filled with cold water or a chemical refrigerant. Refrigeration machines may be used to chill the water or refrigerant that flows through these coils (see Refrigeration (Mechanical refrigeration)). Other air conditioners may use cold water that comes from a well, a river, or a city’s water system.

Most air conditioners used in large buildings heat air by blowing it over coils filled with hot water or steam. A boiler heated by a gas or oil burner produces the hot water or steam. In some air conditioners, electric heaters warm the air. These heaters have a screen of wires heated by electricity. The air is warmed as it passes through the screen.

Controlling the moisture.

The evaporation of moisture from our skin helps cool our bodies. But in summer, air often becomes humid (moist). Humid air cannot pick up as much extra moisture as dry air can. We find it difficult to cool off in humid weather, because the air does not absorb the perspiration from our bodies. The amount of moisture that people lose as perspiration depends on their activities and emotions. For example, a crowd at a basketball game perspires more than an audience in a motion-picture theater. An air conditioner must remove warm, moist air from a room and supply cool, dry air. Otherwise, the air becomes sticky and we feel uncomfortable.

The amount of moisture in air compared with the amount it can hold is called the relative humidity (see Humidity). People usually feel most comfortable when the relative humidity is kept between 30 and 60 per cent.

Air conditioners can dehumidify (remove moisture from) air in several ways. Cold air cannot hold as much moisture as warm air can. When air conditioners cool air by passing it over cooling coils, the water or refrigerant in the coils can be made cold enough to cause the moisture in the air to condense (turn into a liquid). The same process occurs when the outside of a drinking glass becomes moist as it is filled with ice water.

Air conditioners also can remove moisture from air by passing it through sprays of cold water. These sprays cool the air enough to condense some of the moisture.

Moisture control is important in winter, too. Cold outside air contains little moisture. When this air is heated, it becomes extremely dry. Such air dries the skin and may irritate the nose, throat, and lungs. To prevent these discomforts, air conditioners add moisture to the air in cold weather. They do this by passing air through sprays of water or over pans of heated water. The water evaporates into the air.

Circulating the air

is important because most people feel uncomfortable in motionless air. The air in a room often becomes filled with moisture and odors. This air must be removed as conditioned air is blown in.

Fans blow conditioned air through the room. The air may be blown in directly or through ducts (pipes) that lead to various parts of a building. In large commercial buildings, other fans suck out used air. To eliminate smoke and odors, the fans exhaust some of the used air by blowing it out of the building. The remaining used air is returned to the air conditioner, where it is mixed with ventilation air drawn in from outside. This mixture of inside and outside air is then conditioned and returned to the cooled room. Eventually, an air conditioner replaces all the air in a room or building with ventilation air drawn in from outside. An air conditioner can circulate air through a room at a rate of about 15 to 40 cubic feet (0.4 to 1.1 cubic meters) per minute. The amount of air circulated through a room depends on the size and speed of the fan used in the air conditioner.

Kinds of air conditioners

Room air conditioners

operate on electricity or gas, and are located partly in the room to be cooled. They are enclosed in a single cabinet. They blow the conditioned air directly into the room and do not have air ducts leading to and from them. The three chief types are (1) window air conditioners, (2) consoles, and (3) self-contained air conditioners.

Window air conditioners

fit into the lower part of a window and can be moved from window to window. In the air-conditioning industry, these units are called room air conditioners.

Consoles

are larger than window air conditioners and stand on the floor in the room. They must be near a window or a wall opening in order to obtain outside air.

Self-contained air conditioners

are the largest room air conditioners. They may stand 7 feet (2 meters) tall, and can cool an entire large room, such as a restaurant.

Central air conditioners

use electricity or gas. They can supply conditioned air to a number of rooms or to an entire building from one central source. Fans blow the conditioned air through air ducts from the air conditioner to the rooms.

Central conditioners have a number of advantages over other kinds. For example, all the equipment for air conditioning a large area is located in one place. This reduces the cost of cleaning and repairing. Central conditioners can also be zoned. That is, they can supply air of different temperatures to different parts of a building. A doctor with a crowded waiting room might want cooler air than a lawyer in a smaller office. Zoning makes it possible to serve both their needs.

Combination room and central air conditioners

are used in large buildings. They combine the advantages of both types. One kind of combination system has a central conditioner to condition outside air. It circulates the conditioned air to a unit in each room. The room unit controls the temperature and moisture-content of the air.

Another type of combination system furnishes cold water or a refrigerant from a central refrigeration machine to a conditioner in every room. Each room conditioner has a fan, filter, and cooling coils to condition and circulate the air.

A third variety of combination system conditions a mixture of outside and inside air. This system supplies each room with cool, conditioned air through one duct, and warmed, conditioned air through another duct. A mixing-box unit in each room mixes the two air streams to provide the right temperature. Combination systems have the advantage of supplying conditioned air or a cooling fluid from a central source. This cuts the cost of maintaining them. At the same time, the individual room units allow the people in each room to adjust the temperature to suit their wishes.

Air conditioners for vehicles.

In automobiles, the refrigeration unit is located under the hood near the engine. The engine drives the unit by means of a belt connected to the engine. Air ducts feed the conditioned air into the car.

Buses often have a separate motor to drive the refrigerating equipment. This equipment may be located either in the rear of the bus or under one side near the luggage compartment. The air conditioner is in the roof of the bus. It supplies cool, conditioned air to the seats through ducts running along the roof.

In a railroad passenger car, an electric motor or a gasoline engine drives a refrigeration unit located under the car. The air conditioner is mounted over the entrance at one end of the car. Fans in the conditioner blow the air through ducts to outlets that are located in the car.

Airplanes require special air-conditioning units. Much of the equipment is made of aluminum to save weight. The refrigeration and air-conditioning units for large airplanes are usually located in the wings. In smaller aircraft, these units may be in the body of the airplane. Air turbines drive the refrigeration equipment. Air ducts feed the conditioned air to different parts of the airplane.

On ships, the refrigeration equipment is installed in the engine room or in a mechanical equipment room. The air-conditioning units are located throughout the ship. Air-conditioning equipment for ships must be extra strong to withstand the rolling and pitching motion of the water. Special metals are used to resist corrosion by seawater.

Choosing a window air conditioner

Two facts should be kept in mind when selecting a window air conditioner. (1) The capacity (cooling power) of the air conditioner should be suitable for the room. (2) The electric power requirements for the air conditioner must match the electric system available for it.

Capacity of air conditioners.

The size of a room and the number of people using it help determine the capacity of the air conditioner needed. So do the number, size, and direction of the windows in a room, the wattage of appliances and lights, and the amount of wall insulation.

An air conditioner that has a lower capacity than needed will not keep a room cool. An oversized unit will control the temperature, but it may not reduce excess humidity. Such a unit will run only a short time before the temperature falls. It may not even run long enough to remove much moisture from the air.

Manufacturers rate the capacity of air conditioners in four ways: (1) British thermal units, (2) watts and kilowatts, (3) tons of refrigeration, and (4) horsepower.

British thermal units.

One British thermal unit (Btu) equals the amount of heat needed to raise the temperature of 1 pound (0.45 kilogram) of water from 59 °F to 60 °F (15 °C to 15.56 °C). The Btu per hour rating is the basic measurement for air conditioning, and should always be used to specify the capacity of an air conditioner. An air conditioner with a capacity of 12,000 Btu’s per hour can remove enough heat from the air it is conditioning to raise 12,000 pounds (5,440 kilograms) of water one degree Fahrenheit each hour. The cooling capacities of room air conditioners range from 4,000 to 36,000 Btu’s per hour.

Watts and kilowatts

are the units used to measure air-conditioner capacity in the metric system. One watt equals 3.4 Btu’s per hour.

Tons of refrigeration.

One ton of refrigeration removes the amount of heat needed to melt 1 short ton (0.9 metric ton) of ice at 32 °F (0 °C) in 24 hours. A one-ton air-conditioning unit can remove 288,000 Btu’s of heat in 24 hours, or 12,000 Btu’s per hour (3,510 watts). A two-ton air-conditioning unit can remove twice this amount, and so on.

Horsepower

measures the power needed to run the refrigeration equipment that cools the air. One horsepower equals 745.7 watts.

Electric power requirements.

Local electrical codes govern the kind of motor that can be connected to different kinds of electrical systems. Most air conditioners that have a capacity rating of up to 14,000 Btu’s per hour operate on 110-volt, single-phase current. Larger air conditioners need either 220-volt or 220-440-volt, three-phase current. See Electric generator (Kinds of AC generators).

Different air conditioners use various amounts of electricity to remove the same amount of heat. Engineers use a number, called the Energy Efficiency Ratio (EER), to measure how economically an air conditioner uses electricity. To find an air conditioner’s EER, its Btu per hour rating is divided by the number of watts of electricity used by the unit. For example, an air conditioner that uses 600 watts to remove 5,000 Btu’s per hour has an EER of 5,000 divided by 600, or 8.33. Most air conditioners have an EER of from 8 to 9. The higher the EER of a unit, the less electricity it uses–and the less it costs to operate.

History

The ancient Egyptians, Greeks, and Romans used wet mats to cool indoor air. They hung the mats over the doors to their tents and other dwellings. When wind blew through the mats, evaporation of the water cooled the air. The people of India later used this method to cool the royal palaces. About 1500, Leonardo da Vinci, the great Italian artist and scientist, built the first mechanical fan to provide ventilation. Water power turned the fan. In 1553, the English developed a rotary fan to ventilate mines.

Textile manufacturers made the first attempts at air conditioning. In 1719, a silk company in Derwent, England, installed a central system to heat and ventilate its mill. Early cloth makers in New England boiled water in huge pots near their looms to keep the air moist. Unfortunately, the heat injured the health of the workers and this method was discontinued.

About 1838, David B. Reid, an English scientist, provided the British House of Commons with a system to ventilate and humidify the air. In the mid-1800’s, John Gorrie, an American, invented a cold-air machine to cool hospital rooms.

During the late 1800’s, textile manufacturers in New England began using sprays of water to condition the air in their mills. In 1897, Joseph McCreery of Toledo, Ohio, received a patent for the type of spray now used in air conditioners.

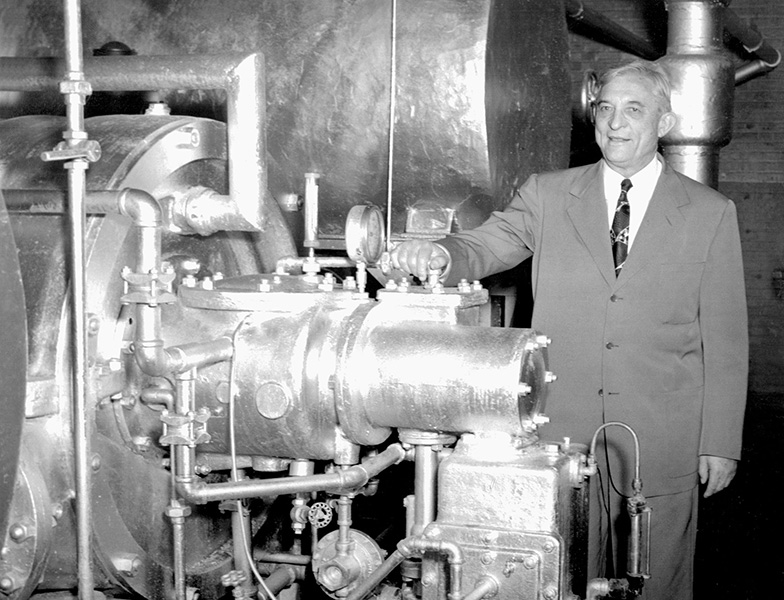

By 1902, Alfred R. Wolff, a consulting engineer, had designed air-cooling systems for Carnegie Hall and several other buildings in New York City. That same year, Willis H. Carrier, a research engineer, designed the first scientific system to clean, circulate, and control the humidity of air.

In 1906, Stuart W. Cramer, a textile engineer from Charlotte, N.C., used the term air conditioning for the first time. Air conditioning became a recognized branch of engineering in 1911.

The Baltimore & Ohio Railroad installed the first air-conditioning system for trains in 1931. Air conditioning of apartments and homes also began during the 1930’s. In 1939, Packard Motors introduced air-conditioning units for automobiles. The Greyhound Corporation installed the first bus air-conditioning systems in 1940. By the early 2020’s, about 90 percent of all housing in the United States had some form of air conditioning. In addition, most of the new single-family homes that were built in the United States were equipped with central air conditioning.

Careers in air conditioning

Careers in air conditioning can be divided into five main fields: (1) designing, (2) manufacturing, (3) selling, (4) installing and servicing, and (5) teaching and research. College-educated engineers research and design air-conditioning systems. Skilled machinists, toolmakers, cabinetmakers, and similar craftworkers help manufacture air conditioners. Technical training, such as a degree in engineering, is often essential for positions in the selling and executive branches of air conditioning. Specially trained technicians, and operating and service engineers, install and maintain air conditioners.