Butter is a dairy product used as a spread for bread and in cooking. People make butter by churning (forcefully stirring) cream, the fatty part of raw milk. Butter has a rich flavor. Cooks and bakers use butter in a wide variety of foods.

In the United States, people use butter made from the milk of cows. In some countries, however, butter may be made from the milk of goats, horses, reindeer, sheep, or other animals. Several products are made from butter. These products include ghee and whipped butter. Ghee is made by removing the water and milk solids from butter. It is often used in Indian cooking. Whipped butter has air mixed in it to make it lighter and easier to spread.

Throughout history, people have used butter for various purposes other than for food. In ancient Rome, for example, people used butter as a hairdressing and as a skin cream.

How butter is made

Butter comes from butterfat, which is present in milk and cream in the form of tiny droplets. Butter is churned from cream because cream contains about 10 times as much butterfat as processed milk does. When cream is mixed rapidly at a certain temperature, droplets of butterfat form particles called butter granules. Churning turns these particles into butter. Creameries make butter in a process that has three steps: (1) pasteurization, (2) churning, and (3) packaging.

Pasteurization.

Cream must be pasteurized before churning. Pasteurization kills harmful bacteria and prevents butter from spoiling. There are two types of pasteurization, batch pasteurization and high-temperature short-time pasteurization. In batch pasteurization, the cream must be heated to at least 165 °F (74 °C), and held at this temperature for at least 30 minutes. In the high-temperature short-time process, the temperature must reach 185 °F (85 °C) for at least 15 seconds.

Churning

involves beating or stirring cream to turn butterfat into butter. Before churning, cream must be kept in storage tanks at 40 to 50 °F (4 to 10 °C) for several hours. During storage, a process called tempering occurs, which makes cream easier to churn.

Most butter made in the United States is sweet cream butter. It is made from sweet (fresh) cream. Cultured butter is made from cream that has soured. To make cultured butter, a creamery adds bacteria to cream before churning it. The bacteria change sugars in the cream to acid, which gives the resulting butter a tangy flavor and helps preserve its freshness. Salt may be added to help preserve either sweet cream or cultured butter.

During churning, creameries sometimes color butter with various food dyes. The natural color of butter varies from pale to deep yellow, depending on the breed of cow and the feed it ate. A feed consisting of fresh green grass makes butter a deeper yellow than does a feed made of grain or hay.

There are two methods of churning cream into butter. These methods are continuous churning and conventional churning.

Continuous churning

is done by large machines that make butter by rapidly beating cream. The beating process causes the formation of a mixture of butter granules and a milky liquid called buttermilk (see Buttermilk ). This mixture passes through a tube-shaped device that looks like a cannon. There, the buttermilk drains off, and the butter is left behind. Continuous churns can turn cream into butter in three minutes or less. They make smoother and more evenly colored butter than do conventional churns. Continuous churns also cost less to operate.

Continuous churns produce most of the butter made in North America and Europe. They turn out a steady flow of butter, rather than only a certain amount at a time, as do conventional churns. Continuous churning results in a more uniform product.

Conventional churning

takes place in large stainless steel drums. Each drum is filled from a third to half of its capacity with cream and is then rotated for about 30 to 45 minutes. Butter granules and buttermilk form after that time. The buttermilk is drained away, and the butter granules are rinsed in cold water. Then most of the water is drained off, and salt may be added. The drum continues to rotate until the butter granules, the remaining water, and the salt have all blended. A conventional churn can produce as much as 8,500 pounds (3,860 kilograms) of butter at a time.

Packaging.

Machines cut the butter into rectangular blocks called prints. The same machines then wrap the prints in waxed paper and put them into packages for sale. Butter may also be packed in 68-pound (31-kilogram) cubes for storage or for wholesale use.

Composition and food value

Butter gets its food value primarily from the butterfat it contains. Standards set by the United States Department of Agriculture require that butter consist of at least 80 percent butterfat. Most butter averages about 80.5 percent butterfat. Butter contains cholesterol, a fatty substance that makes up a part of all animal tissue. See Cholesterol .

The Agriculture Department sets standards for grading butter based on color, flavor, texture, and other qualities. The best butter has the rating U.S. Grade AA. Butter has about 3,240 calories per pound (7,143 calories per kilogram) and ranks as a good source of vitamin A. Because butter is mostly fat, eating large amounts of it can lead to health problems.

History

Historians do not know when people first made butter. People in India churned butter from the milk of water buffaloes as early as 2000 B.C. Until the development of commercial creameries, people used many kinds of clay or wooden churns to make butter. Some churns had a device called a dasher to stir the cream.

The first creamery to make large quantities of butter by machine opened in Orange County, New York, in 1856. In 1879, Carl Gustaf de Laval, a Swedish engineer, patented a device called the centrifugal separator for removing cream from milk. His invention greatly increased butter production. The first continuous churn began to make butter in 1937 in Australia.

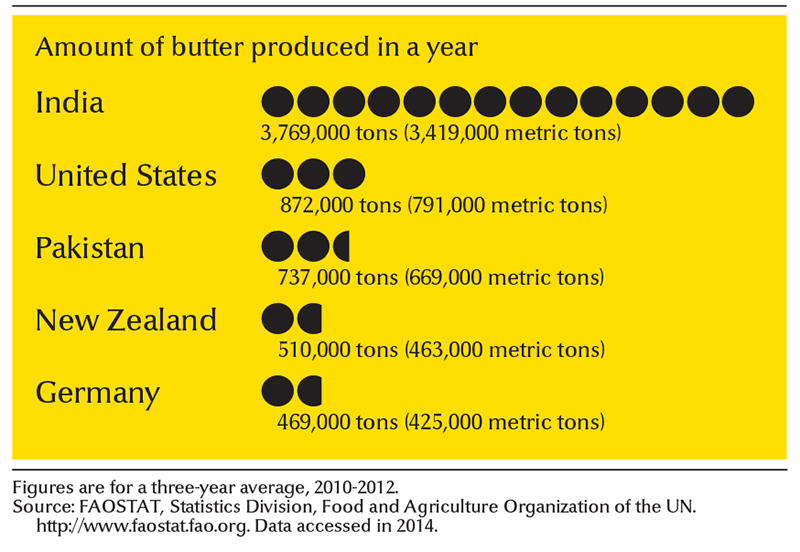

The use of butter reached its highest level during the 1920’s and 1930’s. Thereafter, the increasing popularity of margarine reduced the sale of butter. Margarine usually costs less than butter and can be used in similar ways. Some producers sell blends of margarine and butter. Today, the leading butter-producing countries include France, Germany, India, New Zealand, Pakistan, and the United States.