Chocolate is a food made from the seeds of a tropical tree called the cacao. Botanists believe the cacao tree originated in the northern Amazon River Basin in South America. The word chocolate comes from chocolatl, a word Spanish conquerors may have created by combining the Maya word chocol, which means hot, with the Aztec word atl, which means water. Plain chocolate is extremely bitter. The chocolate in candies and other treats is highly sweetened.

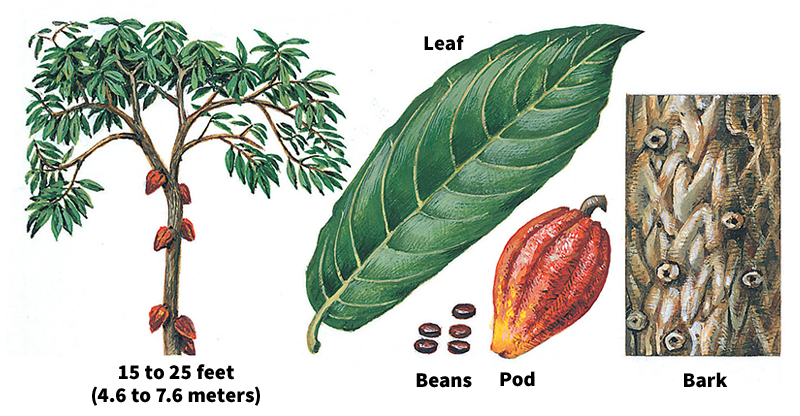

The cacao tree

produces the seeds, or cacao beans, from which all chocolate is made. The scientific name of the cacao tree is Theobroma cacao. The trees flourish in tropical climates within 20 degrees latitude north and south of the equator. Most of the world’s cacao beans come from the west coast of Africa. Côte d’Ivoire is, by far, the world’s leading cacao bean producer. Other major producers include Ghana, Indonesia, and Nigeria.

The cultivated cacao tree grows about 25 feet (7.6 meters) high. It produces leaves, flowers, and fruit in all seasons of the year. The flowers are small. They grow singly and in clusters on the main stem of the branches and on the trunk. The ripe fruit, or pod, may be red, yellow, golden, pale green, or a combination of these colors. The melonlike pod contains 20 to 40 almond-shaped seeds. When these seeds are fermented and dried, they become the commercial cacao bean. Because of a mistake in spelling, probably made by English importers many years ago, these beans became known as cocoa beans in English-speaking countries.

Harvesting the cacao beans.

Workers cut the pods from the trees with knives attached to long poles, or with machetes. They gather the pods into heaps, cut them open, and scoop out the beans. The beans are placed in piles, covered with banana leaves, and allowed to ferment for 2 to 9 days. Some large operations ferment the beans in boxes instead of piles. Next, the beans are dried in the sun or with warm air to prevent mold. Workers then place the beans in bags or bulk containers for shipment.

Manufacturing chocolate.

Chocolate manufacturers receive many types of beans. They blend them to yield the flavor and color desired in the final product. The first steps in processing the beans include cleaning, roasting, hulling, blending, and grinding. Cacao seeds with the shells removed are called nibs. The nibs are quite dry, even though they contain about 54 percent cocoa butter, the natural fat of the cacao bean. The grinding process releases the cocoa butter from within the nibs. The mixture of cocoa butter and finely ground nibs forms a free-flowing substance known as chocolate liquor.

Chocolate products

include unsweetened chocolate, cocoa, milk chocolate, dark chocolate, and white chocolate.

Unsweetened chocolate,

also called baking chocolate, is the commercial form of chocolate liquor. Manufacturers cool and solidify the chocolate liquor into cakes or bars. Unsweetened chocolate is almost always used as an ingredient in such sweet foods as cake and fudge because it tastes bitter and unpleasant on its own.

Cocoa.

In making cocoa powder, workers use huge hydraulic presses to force some of the cocoa butter out of the heated chocolate liquor. The mass remaining in the presses forms large, hard cakes called press cakes. Manufacturers grind press cakes into fine, reddish-brown cocoa powder. People can prepare hot chocolate from the cocoa powder by adding sugar and hot milk. Confectioners, bakers, ice cream manufacturers, and other food producers use cocoa in many of their products.

Dutch-processed cocoa powder is made from cacao nibs that have been soaked in a special solution before being ground into liquor. The solution lowers the chocolate’s acidity. Dutch-processed cocoa powder has a darker color and a less sour flavor than regular cocoa powder.

Milk chocolate

ranks as the sweetest and most popular of all chocolate products. The basic ingredients of milk chocolate are chocolate liquor, additional cocoa butter, whole milk solids, and sugar. Many milk chocolates are more than half sugar by weight. Manufacturers may also add small amounts of flavoring, such as vanilla and salt. The ingredients are mixed well. The mixture then passes through a series of large, steel roll refiners that crush the sugar and milk powder to produce a fine paste. Machines called conches then process the chocolate for up to 72 hours. The mixing action of the conch helps develop a smooth texture.

Dark chocolate

is processed in the same way as milk chocolate, but it contains less sugar and little or no milk solids. It is also called bittersweet or semisweet chocolate. Dark chocolate is sometimes sold based on the percentage of cacao it contains. Chocolates with higher cacao percentages are less sweet and have a more intense chocolate flavor.

White chocolate

is made from sweetened cocoa butter. Because it lacks cocoa solids, which give chocolate its characteristic flavor and color, some people do not consider white chocolate to be “true” chocolate.

History.

The Mayo-Chinchipe people, who lived in what is now Ecuador, may have been the first people to cultivate cacao around 3500 B.C. By about 1200 B.C., the Olmec were growing cacao in southern Mexico. They consumed cacao beverages in religious ceremonies. Cacao was a valuable trade item for the Maya of Central America as early as 600 B.C. Cacao was important in the traditions and religion of the Aztec in Mexico by A.D. 1300. Members of the Aztec elite and warrior classes drank a beverage made of ground cacao mixed with ground corn and other seeds. They may have added honey to sweeten the drink, or mixed in vanilla or chili powder to add flavor. The Maya and Aztec also used cacao beans as a currency.

Spanish explorers and conquistadors in Mexico first tasted cacao during the early 1500’s, but it is not known whether they brought the beans back to Spain. However, chocolate had arrived in Spain by the mid-1500’s. The first commercial shipment of cacao beans to Europe arrived in Spain in 1585. Chocolate became a popular drink of European nobility soon afterward. In London, the first establishment to sell cocoa opened in 1657. Europeans added sugar, vanilla, cinnamon, and milk to the beverage to reduce the bitter taste.

The British chocolate company J. S. Fry and Sons is credited with developing solid eating chocolate. The company first made the confection in 1847. In 1876, the Swiss chocolate manufacturer Daniel Peter invented a method to produce milk chocolate. Today, chocolate is popular around the world.