Cork is a lightweight, spongy substance obtained from the bark of the cork oak tree. It does not absorb water readily and can be compressed a great deal, but it springs back when released. People used cork as early as 400 B.C. The Romans wore cork sandals and used cork to float anchors and fishing nets. Cork bottle stoppers have been made since the 1600’s.

The tree.

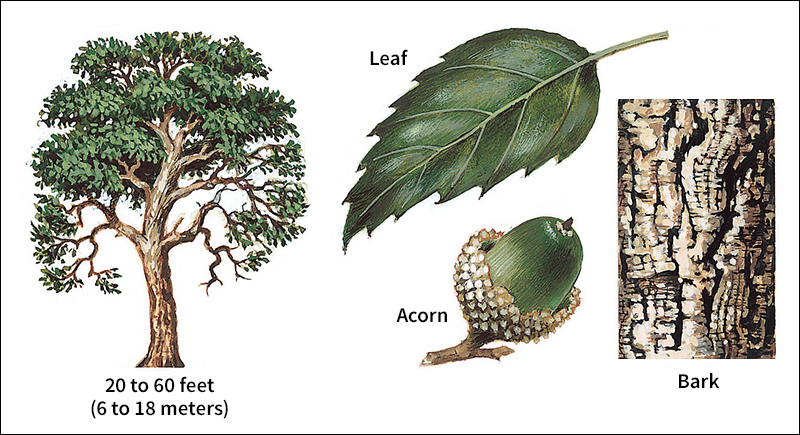

The cork tree is a live oak. This means that it is green the year round. It grows abundantly in Portugal and Spain, where most of the world’s cork is produced. Italy is the third most important country in cork production. The cork oak has been planted in parts of California, and in some of the southeastern states, but the total yield of cork there is small. The outer layer of the bark is dead and is separated from the live inner bark by a layer of water-resistant cells called the phelloderm. These cells have thin walls that become thickened and waxy. The cork tree lives from 300 to 400 years, but it seldom grows more than 50 feet (15 meters) high.

Gathering cork.

A cork tree must be about 20 years old before its bark is thick enough to be stripped. The first layer removed is called virgin bark. Workers strip the bark in June, July, and August. Each tree can be stripped about once every 8 to 10 years. The best cork comes after the tree has been stripped twice.

A cork stripper uses a long-handled hatchet to cut long, oblong sections of bark from the top of the lowest branches to the bottom of the tree. The sections of bark are pried off carefully with the wedge-shaped handle of the hatchet. New phelloderms continue to form so that more cork is produced after each stripping. Cork will never grow again on a spot where the stripper’s hatchet has damaged the live inner layer of bark down to the cambium. Cells in this tissue divide to form new layers of wood and bark cells.

Preparation for market.

The slabs of stripped cork are boiled, and a rough, gritty outer layer is scraped off. The boiling dissolves tannic acid from cork, and softens the material so that the slabs can be straightened out. The slabs are then dried and packed in bundles. Before being loaded on ships, cork is sorted according to quality and thickness.

Uses.

Most cork is used for insulation. For this purpose, it is ground and pressed into boards and pipe coverings. In this form, cork covers the walls and freezing pipes of thousands of cold-storage plants, meat-packing factories, ice cream plants, and oil refineries. Cork floats in water and is used in making buoys and floats for fishing nets. Linoleum is made by mixing cork powder with linseed oil and spreading this paste over canvas or burlap. Floors, walls, and ceilings are made soundproof with corkboard. One of its principal uses is for “corks,” or bottle stoppers. Thin cork gaskets seal metal bottle caps. In addition, cork is used in waterproof coatings, in balloon fabric, and as wadding for shotgun cartridges. Cork shavings are burned to make Spanish black, or cork black, which is a paint used by artists.