Furnace is a device in which heat is produced. Some furnaces heat the air in people’s homes. Others produce steam to run electric power plants. Furnaces are necessary in the manufacture of iron and steel, glass, pottery, and other products. They also are used in petroleum refining. This article deals with both industrial and home heating furnaces. For further information on home heating systems, see the article on Heating.

Furnaces range in size from kitchen ovens to the huge furnaces used in steel production. Most industrial furnaces are built of refractory (heat-resistant) bricks, which are able to withstand great variation in temperature without weakening. The walls and roofs of some modern furnaces are made of refractory fiberglass cloth that is mounted on metal frames. The combustion chamber in most home heating furnaces is made of steel.

Sources of heat.

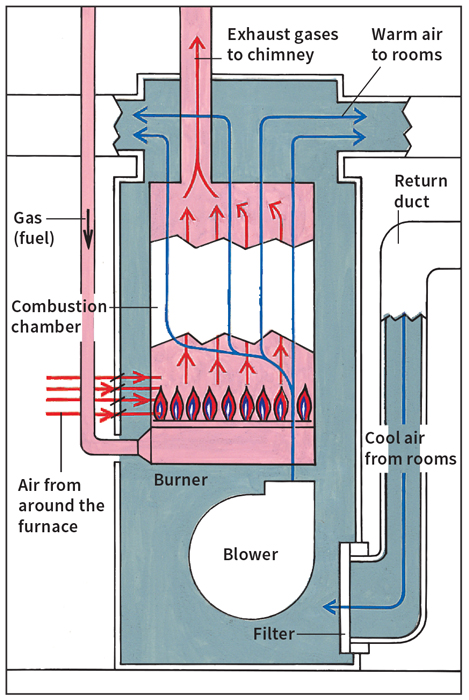

Most furnaces generate heat by burning fuel. These furnaces are called combustion furnaces. Early combustion furnaces burned wood or charcoal. During the 1600’s, coal began to replace these fuels. During the mid-1900’s, many industrial furnaces were converted to burn oil. Today, most industrial combustion furnaces burn natural gas. This fuel causes almost no air pollution. Natural gas also is easy to control. Most home heating furnaces burn gas or oil.

There are two basic types of combustion furnaces–direct-fired and indirect-fired. In direct-fired furnaces, the flame is in the same compartment as the charge (the material to be heated). In an indirect-fired furnace, also called a muffle furnace, the flame is contained in a separate chamber from the charge. This chamber, called a muffle, may be a cavity in the furnace wall or a steel tube that runs through the furnace. Indirect-fired furnaces are used when the charge may be harmed by the gases produced during combustion.

Combustion furnaces can be heated to the temperature required to perform a wide variety of jobs simply by burning the fuel. Some jobs, however, such as smelting iron ore or melting glass, need a higher temperature than the combustion of fuel alone can produce. In such cases, the flame is made hotter by burning the fuel with pure oxygen or by heating air before it is mixed with the fuel. For example, air is drawn into a glassmaking furnace through a pile of bricks that has been heated by hot gases leaving the furnace.

Not all furnaces are heated by the combustion of fuel. For example, electric furnaces use electric power to produce heat. Nuclear reactors get their heat from the energy released when the nuclei of uranium or plutonium atoms split. Solar furnaces have mirrors that focus the sun’s rays on an object that absorbs energy from the rays. See Electric furnace ; Nuclear energy ; Solar energy (Solar heating) .

Heating the charge.

There are two basic types of furnaces, based on the way they heat a charge: (1) batch furnaces and (2) continuous furnaces.

Batch furnaces heat materials singly or a group at a time. Clay pots, for instance, are baked in batches in kilns (ovens). After baking, all the pots are removed before the next batch is placed in the kiln.

Handling the hot charges is often a problem in batch processing because of the high temperatures required in industrial furnaces. A number of solutions have been developed. Workers use steel tongs to remove small articles from batch furnaces, and large mechanical arms and cranes handle larger items. In a car bottom furnace, a type of batch furnace, the floor and door are on wheels and can be pulled out like a drawer to reach the charge. A top hat furnace can be lifted off its base to be loaded or unloaded. Batches of steel and copper are heated in large pot furnaces. Once the materials are melted, the whole furnace is tilted and the glowing hot liquid pours out a spout.

Continuous furnaces heat a steady flow of material that passes through them. This material may be rolled through the furnace on carts, pushed through by hydraulic rams, or carried on conveyor belts. Crude oil and water pass through furnaces in pipes. Some furnaces rely upon gravity to move the material through them. For example, iron ore is fed in at the top of a blast furnace, and molten iron flows out from the bottom. Cement is produced by roasting crushed limestone in a rotary kiln, a slightly inclined, long steel tube lined with refractory brick. The pieces of limestone are fed in at the higher end and slowly tumble to the lower end as the kiln rotates.