Bridge is a structure used by people and vehicles to cross areas that are obstacles to travel. Engineers build bridges over lakes, rivers, canyons, and busy highways and railroad tracks. Without bridges, people would need boats to cross waterways and would have to travel around such obstacles as canyons and ravines.

Bridges range in length from a few feet or meters to several miles or kilometers. A bridge must be strong enough to support its own weight as well as the weight of the people and vehicles that use it. It also must resist natural occurrences, including earthquakes, strong winds, and changes in temperature. Most modern bridges have a concrete, steel, or wood framework and an asphalt or concrete roadway. The roadway is the part of a bridge on which people and vehicles travel.

Most bridges are held up by at least two supports set in the ground. The distance between two adjacent supports is called a span of a bridge. The supports at each end of the bridge are called abutments, and the supports that stand between the abutments are called piers. The total length of the bridge is the distance between the abutments. Most short bridges are supported only by abutments and are known as single-span bridges. Bridges that have one or more piers in addition to the abutments are called multi-span bridges. Most long bridges are multi-span bridges. The main span is the longest span of a multi-span bridge.

A pontoon bridge has no piers or abutments. It is supported by pontoons (flat-bottomed boats) or other portable floats. See Pontoon bridge.

Kinds of bridges

There are seven main kinds of bridges: (1) girder bridges, (2) truss bridges, (3) arch bridges, (4) cantilever bridges, (5) suspension bridges, (6) cable-stayed bridges, and (7) movable bridges.

The types of bridges vary in total length, the length of their spans, and the weight they can support. Before deciding which kind to build at a particular place, engineers determine the length of the structure and of each span. They also must consider the maximum load that the bridge will carry and the materials available to construct the bridge.

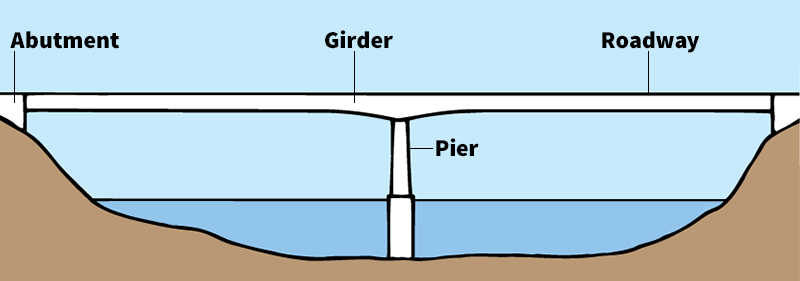

Girder bridges,

which include many highway bridges, are made of beams called girders whose ends simply rest on piers or abutments. These bridges may be used to cross most areas. The span length of girder bridges ranges up to about 1,000 feet (300 meters).

There are two main types of girder bridges. In one type, called a box girder bridge, each girder looks like a long box that lies between the piers or abutments. The top surface of the bridge is the roadway. Box girder bridges are built of steel or concrete. In the other type of girder bridge, the end view of each girder looks like an I or a T. Two or more girders support the roadway. This type of bridge is called a plate girder bridge when made of steel, a reinforced or prestressed concrete girder bridge when made of concrete, and a wood girder bridge when made of wood.

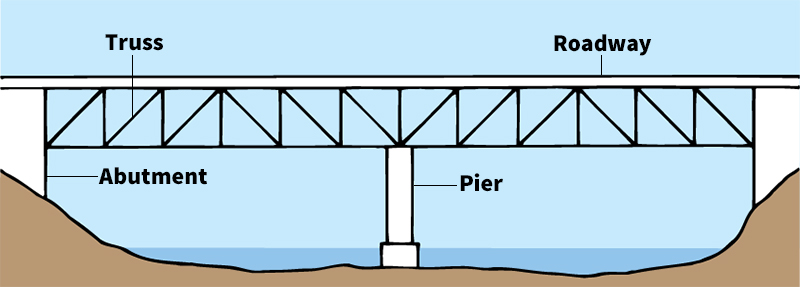

Truss bridges

are supported by frameworks called trusses. The parts of the trusses are arranged in the form of triangles. Such bridges are built over canyons, rivers, and other areas. A truss bridge may have a main span that extends more than 1,000 feet (300 meters).

Each truss consists of steel or wood parts that are connected to form one or more triangles. The simplest truss consists of three parts fastened together at their ends to form a triangle.

Most truss bridges have one set of trusses on each side of the roadway. The majority of modern truss bridges have the roadway on top of the trusses and are called deck truss bridges. The roadway of a through truss bridge runs between the trusses.

In a simple span truss bridge, each truss extends between two abutments or piers. In a continuous truss bridge, each truss has three or more such supports.

Some locations are suitable for either a truss bridge or a girder bridge. In such cases, some engineers choose to build a truss bridge because it requires less construction material than the girder type. However, many engineers prefer a girder bridge because it is more attractive and easier to construct and maintain.

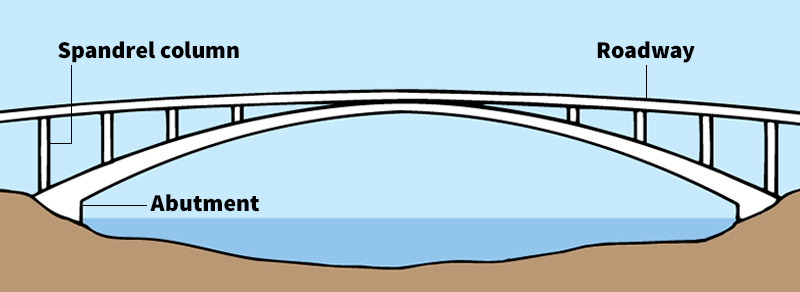

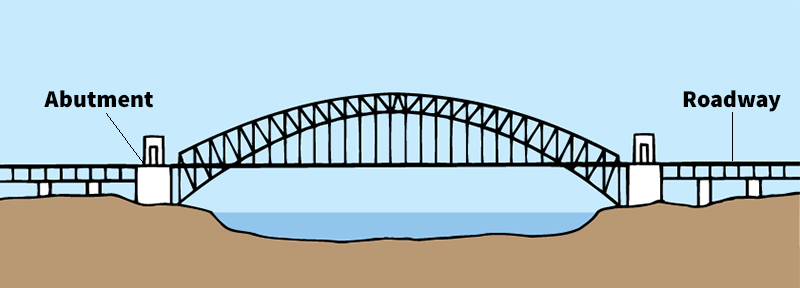

Arch bridges

are structures in which each span forms an arch. The spans range up to about 1,800 feet (550 meters) long. The arch bridge is one of the oldest types of bridges. Early arch bridges consisted of large stone blocks wedged together to form an arch. Today, the majority of arch bridges that have short spans are made of concrete or wood. Arch bridges with long spans are built of concrete or steel. See Arch.

Engineers must design arch bridges so that the sides of the arch do not spread apart and collapse the bridge. The roadway of some arch bridges lies on top of the arch and is supported by vertical columns called spandrel columns. These columns transfer the load of the roadway to the arch, which bears the weight of the bridge. The roadway of a tied arch bridge is below the curve of the arch. The roadway is supported by girders or other types of beams that hang from the arch. The girders or beams also connect to the ends of the arch to prevent the ends from spreading out. The abutments support the weight of the bridge.

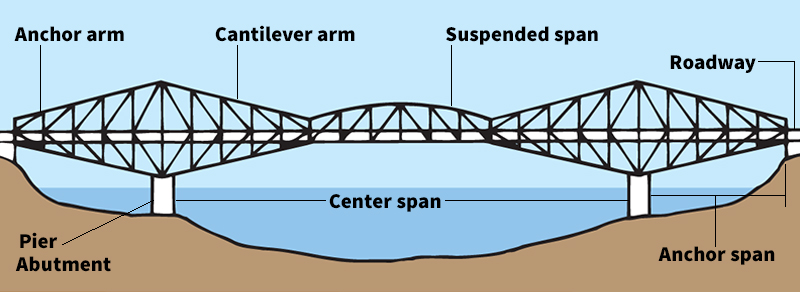

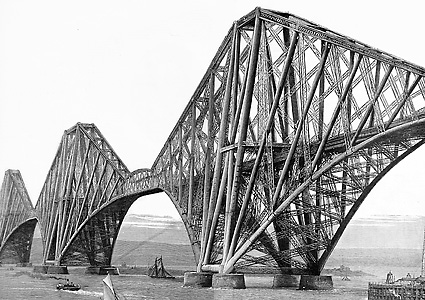

Cantilever bridges

consist of one, two, or several independent beams called cantilevers. These bridges may have spans as long as about 1,800 feet (549 meters). The most common type has two cantilevers, one each extending from opposite banks of a waterway. The two cantilevers are joined together above the middle of the waterway by a beam, girder, or truss.

Each cantilever has two sections, an anchor arm and a cantilever arm. The anchor arm extends between an abutment and a pier. One end of the cantilever arm is supported by the pier, and the other end extends freely over the waterway. The free ends of the two cantilevers are joined together by a suspended span. See Cantilever.

Most cantilever bridges have two anchor spans and one center span. Each anchor span consists of an anchor arm. The suspended span and the two cantilever arms make up the center span.

Many cantilever bridges have truss frameworks. Most bridges of the cantilever type are made of steel or prestressed concrete (see Cement and concrete (Prestressed concrete)).

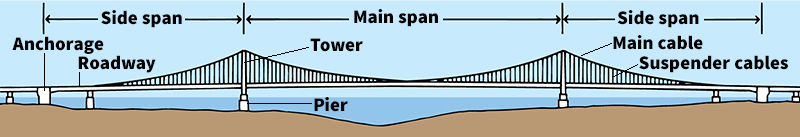

Suspension bridges

are perhaps the most impressive type of bridge because of their long main span and especially attractive appearance. These bridges have a roadway that hangs from steel cables that are supported by two high towers.

Suspension bridges are used to span great distances. Most suspension bridges have a main span more than 1,000 feet (300 meters) long. Some have a main span longer than 4,000 feet (1,200 meters). Suspension bridges also are used to cross deep water or steep canyons, and in other places where the construction of piers is especially difficult and expensive. These bridges require only two piers, each of which supports a tower.

The main span of a suspension bridge stretches between the two towers. Each of two side spans extends between a tower and an anchorage. Most anchorages are huge blocks of concrete set at the ends of the bridge.

The cables that are supported by the towers are called the main cables. A suspension bridge has at least two main cables. Each of these cables extends from one end of the bridge to the other and is secured at each end by an anchorage. The main cables are connected to the top end of vertical suspender cables. The bottom end of each suspender cable attaches to the roadway of the bridge.

A suspension bridge may sway in a strong wind. To minimize such movement, most suspension bridges have a thick structure that supports the roadway. This type of structure helps stiffen the bridge and is called a stiffening girder or stiffening truss.

Loading the player...Tacoma Bridge collapse

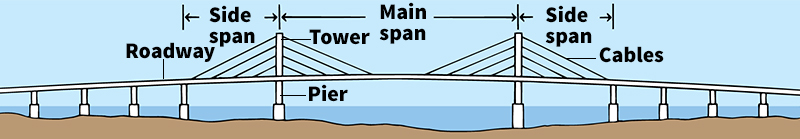

Cable-stayed bridges

resemble suspension bridges. Both have roadways that hang from cables, and both have towers. In a cable-stayed bridge, however, the cables that support the roadway are connected directly to the towers.

A cable-stayed bridge may be used if its foundation can support only one tower. Most cable-stayed bridges have three spans, but some have one tower and two spans. The most efficient cable-stayed bridges have a main span about 700 feet (210 meters) long.

The cables of a cable-stayed bridge may be linked from the roadway to the towers in several ways. The cables may extend from various points on the roadway to the tops of the towers, forming a radiating pattern. The cables form a fan pattern, also called a harp pattern, if they are connected from a variety of points on the roadway to several points on the towers. If the cables are attached from one point on the roadway to various points on the towers, they form a star pattern.

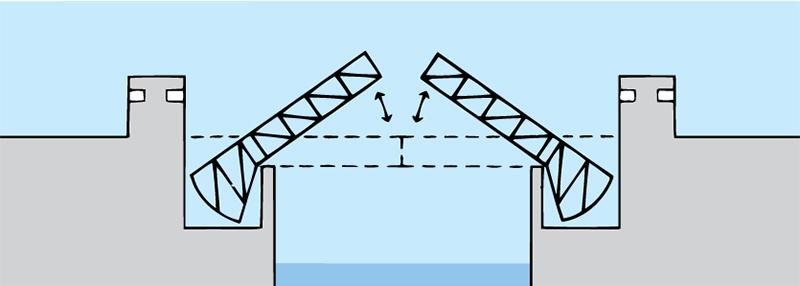

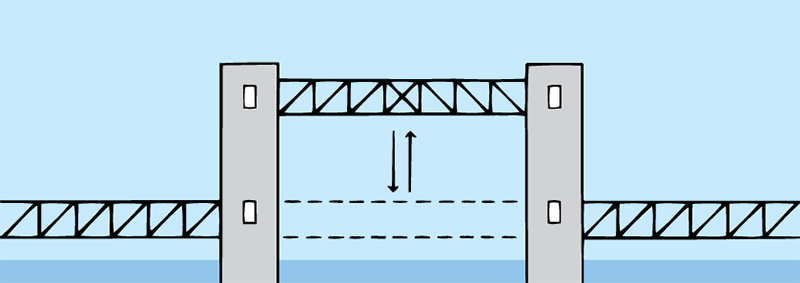

Movable bridges

have a roadway that is moved entirely or partly to provide enough clearance for large ships to pass. There are three types of movable bridges, bascule bridges, vertical lift bridges, and swing bridges. A bascule bridge tilts upward to open. Some bascule bridges open at one end, and others open in the middle. A vertical lift bridge has a roadway that extends between two towers. The roadway rises between the towers, and ships pass underneath. A swing bridge is mounted on a central pier. The bridge swings sideways to enable ships to pass.

History

Logs or vines that extended across streams probably served as the first bridges. The first bridge known to historians was an arch bridge built in Babylon about 2200 B.C. The ancient Chinese, Egyptians, Greeks, and Romans also built arch bridges, using bricks and stone.

During the Middle Ages, from about the A.D. 400’s through the 1400’s, movable bridges called drawbridges were built over the moats of many castles in Europe. Truss bridges were developed in the 1500’s. Most bridges were made of stone or wood until the late 1700’s, when cast iron and wrought iron came into wide use. Many suspension bridges that hung from wrought iron chains were built in the early 1800’s. The first plate girder bridge was finished in 1847. The modern cantilever bridge was introduced about 1870. In the late 1800’s, steel became the main material used for bridges.

The first concrete bridge was built in 1869. A short time later, bridge builders began using reinforced concrete. In the 1930’s, prestressed concrete became an important material for bridge building. The modern cable-stayed bridge was introduced in 1955.