Dye is a chemical solution used to produce long-lasting colors in materials. The textile industry uses dyes to color fibers, yarns, and fabrics. Manufacturers also dye food, fur, ink, leather, paper, plastics, and wood. This article primarily discusses textile dyeing.

Dyes are made from substances called dyestuffs. Until the 1850’s, all dyestuffs came from natural sources, such as parts of plants or animals. Today, industry uses synthetic dyestuffs almost entirely. The dyes they produce hold their color better and cost less than natural dyes.

How dyes work

Dyes must be dissolved before they can work. Manufacturers usually mix them with other substances, such as acid or table salt, to make them dissolve. When textiles go into a dyebath (dye solution), the fibers absorb the molecules of the dye. The absorbed dye molecules either become trapped within the fibers or chemically bond with the fiber molecules. These dye molecules give the fibers the desired color.

Dyed textiles vary in their ability to hold color. However, all textiles can be made colorfast to at least some extent. Many colorfast fabrics resist fading from laundering or sunlight and color changes from such substances as perspiration and chlorine.

To improve the colorfastness of some fabrics, dyers use substances that bond with the dye or fiber molecules, or both. Bonding agents called mordants are used mainly on natural fibers, such as cotton, flax, silk, and wool. The chief mordants include tannic acid and soluble compounds of such metals as aluminum, chromium, copper, iron, and tin.

Kinds of dyes

Synthetic dyes.

The chief kinds of synthetic dyes include (1) acid dyes, (2) azoic or developed dyes, (3) basic dyes, (4) direct dyes, (5) disperse dyes, (6) fiber reactive dyes, (7) premetalized acid dyes, and (8) sulfur dyes and vat dyes. Pigments are sometimes used to color textiles. But they do not dissolve, and so they are not true dyes. Manufacturers use adhesives to fix pigments to fibers.

Acid dyes

are not themselves acidic, but acids must be added to the dye bath to enable the dye to bond with the fiber. Acid dyes are most often used to color nylon, silk, and wool.

Azoic or developed dyes

involve a reaction of two colorless chemicals to produce a colored dye in the fiber. Dyers sometimes use this type of dye to produce bright, wash-fast colors in cotton or rayon fabrics.

Basic dyes,

also called cationic dyes, are dissolved in acid solutions. They are used primarily to dye acrylic and modacrylic fibers. They can produce brilliant colors.

Direct dyes

were the first dyes that could color fibers without the help of a mordant. Table salt helps control the dyeing process and achieve deep shades. Dyers use direct dyes on cotton, flax, and certain rayons.

Disperse dyes

dissolve only slightly in water. They are used to color acetate, acrylic, nylon, and polyester. To dye these fibers, dyers must use heat. The high temperature causes the fibers to swell, which enables the dye to pass into the fiber.

Fiber reactive dyes

form a strong chemical bond with certain fibers, including cotton and rayon. Some types can also color nylon and wool. Fiber reactive dyes produce wash-fast colors, often in bright shades.

Premetalized acid dyes

contain such metals as copper and chromium, which improve colorfastness. Such dyes are widely used on nylon and wool.

Sulfur dyes and vat dyes

are insoluble in water, but when put in an alkaline solution, a chemical reaction enables them to dissolve. Fibers colored with such dyes are then exposed to air to develop their true color and to help fix the dyes. Vat dyes rank among the most colorfast dyes. Sulfur dyes and vat dyes are used chiefly on cotton and rayon.

Natural dyes.

Most natural dyes came from such parts of plants as the bark, berries, flowers, leaves, and roots. The madder plant, which grows in Asia and Europe, supplied bright red dyes for many fabrics, including linen and silk. People in many lands obtained saffron, a yellow dye, from the crocus plant. They used it on such textiles as silk and wool. Natural indigo, a dark blue dye, comes from the indigo plant, which grows chiefly in India. Dyers used it on cotton, wool, and other fibers, and still use it on denim fabrics. Logwood comes from a tree that grows in Central America, Mexico, and the West Indies. It supplies black and brown dyes for such materials as cotton, fur, and silk. Henna, an orange-brown dye made from a shrub of North Africa and the Middle East, was used to color leather. Today, people sometimes use henna to dye their hair or skin.

Leading animal dyes included carmine and Tyrian purple. Carmine, a bright red dye, was made from the dried bodies of an insect found in Mexico and Central America. Tyrian purple, a rare, expensive dye, came from certain shellfish of the Aegean and Mediterranean seas.

Dyeing textiles

Textile manufacturers dye fibers and fabrics at various stages. If manufacturers dye the fibers before spinning them into yarn, the process is called stock dyeing. In yarn dyeing, also called skein dyeing, the fibers are dyed after they are made into yarn. In piece dyeing, which is used for most solid-color fabrics, manufacturers apply the dyes after the yarn is made into cloth. Some dyeing machines pull the fabric through the dyebath. Others have squeeze rolls that force dye into the cloth. Some machines can continuously dye about 100 yards (90 meters) of fabric per minute. Manufacturers print designs on some fabrics. A machine applies different colors to various areas by means of screens or engraved rolls. See Textile.

History

People have used dyes to color fabrics and other materials for more than 5,000 years. In addition, dyers have made use of mordants for several thousand years.

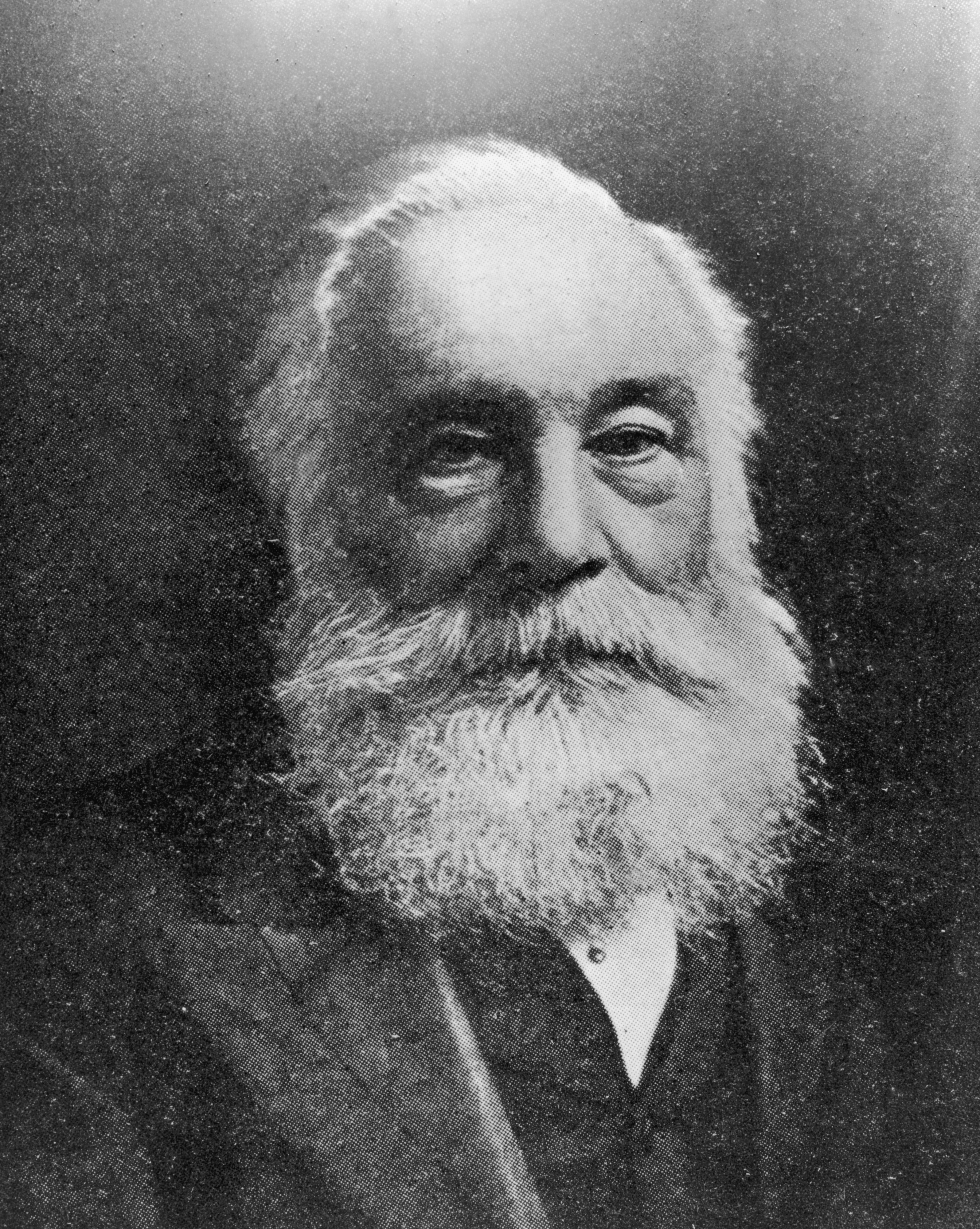

In 1856, William H. Perkin, an English chemist, made the first synthetic dye. This dye, called mauve, is pale purple. Perkin produced it accidentally when he tried to make quinine from a coal-tar product called aniline.

Before World War I (1914-1918), Germany made most of the world’s dyes. During the war, the Germans cut off their supply of dyes. As a result, dye industries in other industrialized countries grew rapidly. Since the 1940’s, chemists have invented many synthetic textile fibers—and have developed thousands of synthetic dyes to combine with them.