Electric generator is a machine that changes mechanical energy—the energy of motion—into electrical energy. Generators produce almost all the electric power used by people. They furnish electric power that runs machines in factories, provides lighting, and operates home appliances. Generators were once called dynamos, a shortened form of the term dynamoelectric.

A generator may be small enough to hold in one hand, such as a generator used to power a hand crank flashlight. Or a generator may be bigger than a house and supply electric power for as many as 1 million homes.

The size of generators is usually measured in kilowatts or megawatts. One kilowatt equals 1,000 watts. One megawatt equals 1,000,000 watts. A giant generator can produce hundreds of megawatts of electric power. See Kilowatt.

There are two main types of generators. Direct-current (DC) generators produce electric current that always flows in the same direction. Alternating-current (AC) generators, or alternators, produce electric current that changes direction many times every second. Both kinds of generators work on the same scientific principles. But they differ in the ways they are built and used.

How a generator works

Basic principles.

A generator does not create energy. It changes mechanical energy into electrical energy. Every generator must be driven by a turbine, a diesel engine, or some other machine that produces mechanical energy. For example, the generator in an automobile is driven by the same engine that runs the car.

Engineers often use the term prime mover for the mechanical device that drives a generator. For a generator to produce more electrical energy, this device must supply more mechanical energy. If the prime mover is a wind turbine, for example, stronger winds must flow through the turbine to produce more electric power.

Generators produce electric power by means of a principle discovered independently by two physicists in the early 1830’s—Michael Faraday of England and Joseph Henry of the United States. They found they could produce electric current in a coil of copper wire by moving the coil near a magnet or by moving a magnet near the coil. This process is called electromagnetic induction. The voltage, or electromotive force, of the electric current produced is called an induced voltage or induced electromotive force. If the wire is part of a closed circuit of wires, the induced voltage causes an electric current to flow through the circuit. See Electric circuit; Electromotive force.

A simple generator

may consist of a U-shaped magnet and a single loop of wire. The area around a magnet where its force can be felt is called a magnetic field. To help describe a magnetic field, we think of lines of force going out from the north pole of a magnet and returning into the magnet at its south pole. The stronger the magnet, the greater the number of lines of force. If you rotate the loop of wire between the poles of the magnet, the two sides of the loop “cut” the lines of force. This induces (generates) electric current in the loop.

In the first half of the turn, one side of the loop of wire cuts up through the lines of force. The other side cuts down. This makes the current flow in one direction through the loop. Halfway through the turn, the loop moves parallel to the lines of force. No lines of force are cut and no electric current is generated. In the second half of the turn, the side of the loop that was cutting upward cuts downward through the lines of force. The other side of the loop cuts upward. This makes the electric current induced in the loop flow in a direction opposite to the first half of the turn. At the bottom of the turn, the loop again moves parallel to the lines of force and no electric current is generated. For every complete turn, the voltage and current that are generated travel in one direction half the time, and in the opposite direction the other half of the time. Twice during each turn no current flows. The voltage and current are known as an alternating voltage and an alternating current. The voltage that a generator produces can be increased by increasing (1) the strength of the magnetic field (number of lines of force), (2) the speed at which the loop rotates, or (3) the number of loops of wire that cut the magnetic field.

One complete revolution of the loop through the lines of force is called a cycle. The number of such cycles in a second is called the frequency of the voltage or current and is measured in units called hertz. One hertz equals one cycle per second. The electric current in North America has a frequency of 60 hertz. In most of the rest of the world, the frequency is 50 hertz.

Electromagnetism.

A loop of wire rotated between the poles of a magnet produces another important electromagnetic effect in addition to generating electric current. When the loop of wire carries current, the current produces a magnetic field around the wire. This magnetic field works against the magnetic field of the magnet. It makes the loop harder to turn. The more electric current induced in the loop, the stronger its magnetic field, and the more difficult it is to turn. That is why the prime mover that turns a generator must furnish increased amounts of mechanical energy to increase the output of current by the generator. This same magnetic force in the loop causes the rotation in electric motors. Under proper circumstances, generators can act as motors, and motors as generators. See Electric motor.

Parts of a generator.

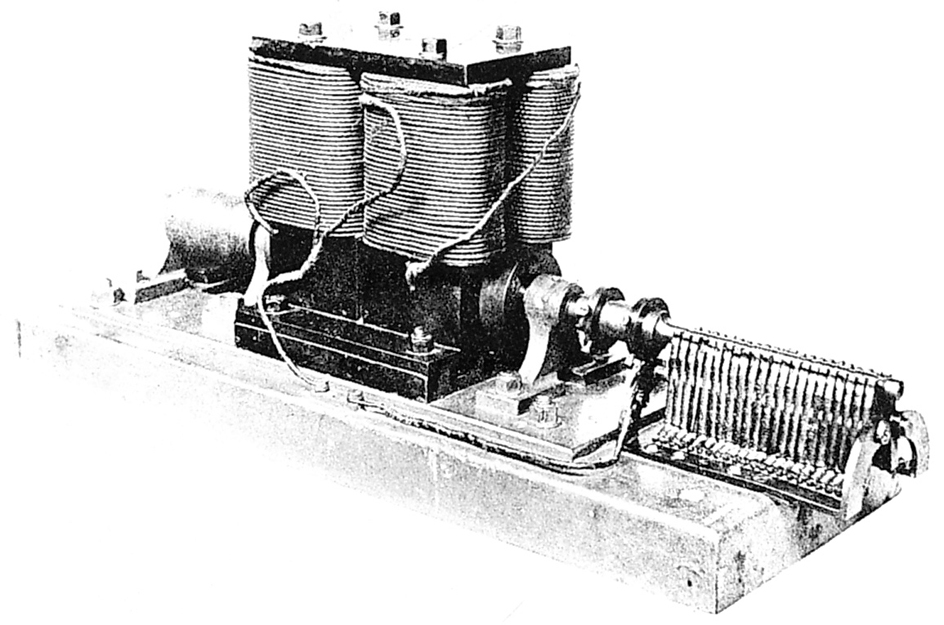

A generator has two main parts: an armature and a field structure. The armature contains coils of wire in which the current is induced. It acts like the loop of wire in the simple generator. The field structure acts like the simple generator’s magnet. It sets up the magnetic lines of force. Electromagnets create the lines of force in most generators (see Electromagnet). Some small generators have permanent magnets. These generators are called permanent-magnet generators. The coils for the armature and field structure are usually insulated copper wire wound around iron cores. The iron cores strengthen the magnetic fields.

Electric current can be generated either by making the armature cut the lines of force, or by making the lines of force cut past the armature. Because of this, either the armature or the field structure can be the rotating part of a generator. The rotating part is called the rotor, and the stationary part is known as the stator.

Losses and efficiency of generators.

Not all of the mechanical energy used to drive generators is converted to electrical energy. Some of it is converted to heat as a result of friction in the bearings supporting the generator rotor, the resistance of the copper coils to the current, and the action of the magnetic lines of force in the iron cores. Thus, generators must be cooled by blowing air through them, or by running a cooling liquid or gas past the coils, iron cores, and bearings. A generator’s efficiency refers to its effectiveness in converting mechanical energy to electrical energy. An efficiency of 90 percent means that 90 percent of the input mechanical energy is converted to electrical energy. The remaining 10 percent is converted to heat and must be carried away by the cooling system. Large generators that use conventional electromagnets as a source of magnetic field can have efficiencies as high as 97 percent. Some generators use superconducting coils as their source of magnetic field. At low temperatures, superconducting coils offer no resistance to the flow of electric current. As a result, these types of generators reach efficiencies of over 99 percent.

Alternating-current generators

The simple generator we have been describing produces alternating current in a loop of wire. To be an alternating-current generator, it needs some way to send the current it produces to the device that will use it. This is done with the help of collector rings, or slip rings, and fixed pieces of carbon called brushes. Each end of the loop of wire is connected to a ring. The rings rotate with the loop of wire. A brush rests against each ring. Each brush is connected to a wire leading to the device that will use the electric power. The current produced in the loop of wire flows in and out of the generator through the rings and brushes to the device.

How AC generators work.

Practical AC generators differ in several ways from the simple AC generator. They are usually equipped with a small auxiliary generator called an exciter. The exciter supplies direct current for the electromagnets used to create the magnetic field in the AC generator. The armature of an AC generator consists of copper wire wound in hundreds of coils around slots cut in an iron core. The electromagnets consist of copper bar wound around iron cores.

In most AC generators, the armature is the stator and the field structure is the rotor. This means that the electromagnets that make up the field structure rotate so the magnetic field sweeps past the armature coils. In these generators, the slip rings are used to carry the direct current from the exciter generator to the electromagnets in the field structure. Outside wires connected to the armature coils take the alternating current induced in the armature directly from the armature. Engineers have found that it is easier to conduct the relatively weak current from the exciter through the slip rings and to take the heavy current produced in the armature directly from the armature. This kind of AC generator is also called a synchronous generator because it generates a voltage that has a frequency proportional to, or synchronized with, the speed of the rotor.

The field structure in an AC generator may have only one electromagnet, but it often has two, three, four, or more. This means that the magnetic field produced by the field structure will have two, four, six, eight, or more poles—two for each electromagnet. The generator produces one complete cycle of current each time a pair of poles passes an armature coil, instead of one cycle for each complete revolution of the field structure. Depending on the number of electromagnets, these generators can produce one, two, three, four, or more cycles for each revolution of the field structure or of the armature. A two-pole AC generator must rotate at 3,600 revolutions per minute to generate a 60-hertz current.

Kinds of AC generators.

In some AC generators, called single-phase generators, the armature has as many sets of coils as the field structure has poles. But most AC generators have three sets of armature coils for each pole. These generators produce three electric currents at one time and are called three-phase generators. They generate more power for the amount of materials used than do single-phase generators. They also lead to better transmission and use of power.

Uses of AC generators.

The main generators in nearly all electric-power plants are AC generators. This is because a relatively simple electromagnetic device called a transformer makes it easy to increase or decrease the voltage of alternating current (see Transformer). Engineers build AC generators that produce current with only a certain voltage. For many large generators, this voltage is 18,000 or 22,000 volts. By means of a step-up transformer, the voltage can be increased as high as 500,000 or 765,000 volts to force the current over long distances. In the area where the current is finally used, a series of step-down transformers lowers the voltage to a usable level. Most household appliances, for example, operate on 120 volts. Some office buildings and factories use voltages ranging from 480 to over 4,000.

Nikola Tesla, a Serbian engineer who came to the United States in 1884, developed the first successful polyphase AC generators, or generators with more than one phase. He also developed electric motors to use alternating current, and transformer systems for changing the voltage of alternating current. Tesla’s inventions made it economically possible to generate current far from the places where the current is used.

Direct-current generators

To change the simple generator into a direct-current generator, two things must be done: (1) the current must be conducted from the rotating loop of wire, and (2) the current must be made to move in only one direction. A device called a commutator performs both tasks.

How DC generators work.

The commutator rotates with the loop of wire just as the slip rings do with the rotor of an AC generator. Each half of the commutator ring is called a commutator segment and is insulated from the other half. Each end of the rotating loop of wire is connected to a commutator segment. Two carbon brushes connected to the outside circuit rest against the rotating commutator. One brush conducts the current out of the generator, and the other brush feeds it in. The commutator is designed so that, no matter how the current in the loop alternates, the commutator segment containing the outward-going current is always against the “out” brush at the proper time. The armature in a large DC generator has many coils of wire and commutator segments. Because of the commutator, engineers have found it necessary to have the armature serve as the rotor and the field structure as the stator.

Kinds of DC generators.

In some DC generators, the direct current needed for the electromagnets that make up the field structure comes from an outside source, just as it does in most AC generators. These DC generators are called separately excited generators. Many other DC generators use part of the direct current they produce to operate their own electromagnets. These generators are called self-excited generators. A self-excited DC generator depends on residual magnetism—that is, a small amount of magnetism that remains in the electromagnets after the generator is shut off. Without this residual magnetism, it would be impossible to start a self-excited generator once it had stopped.

The direct current needed for a self-excited generator’s electromagnets can be drawn from its armature by means of three different connections. These are (1) shunt, (2) series, and (3) compound, a combination of shunt and series connections.

The type of generator used for a certain task depends on the amount of voltage control required. For example, a DC generator used to charge a battery needs only simple voltage control. It might be a shunt generator. A DC generator that supplies electric power for a passenger elevator needs more complicated voltage control. It would be a separately excited generator.

Uses of DC generators.

Many DC generators are driven by AC motors in combinations called motor-generator sets. This is one way of changing alternating current to direct current. Factories that do electroplating and those that produce aluminum, chlorine, and some other industrial materials need large amounts of direct current and use DC generators. So do locomotives and ships driven by diesel-electric motors. Because commutators are complex and costly, many DC generators are being replaced by AC generators combined with electronic rectifiers. Rectifiers are devices that let current flow in one direction only. They permit use of simpler, more rugged AC generators, even when DC is required.