Electric light is a device that uses electric energy to produce visible light. Appliances called fixtures or luminaires hold electric light sources. These appliances are sometimes called lamps. But the word lamp may also refer to the light source itself.

This article deals with the various types of electric light. For much more information on the ways electric lights are used, see the World Book article on Lighting.

There are three main types of electric lights. They are (1) incandescent lamps, (2) gaseous-discharge lamps, and (3) solid-state lights.

Incandescent lamps

The incandescent lamp is the oldest form of electric light. In an incandescent lamp, electric current passes through a wire called a filament, heating it. At high temperatures, the filament glows brightly, much as does a hot metal poker. This effect is called incandescence. The filament is usually made of tungsten, a metal that can withstand high temperatures without melting. A bulb, usually made of glass, surrounds the filament. The bulb typically holds a mixture of nonreactive gases that helps the filament to last longer. A metal base holds the parts in place and connects the light to an electric circuit.

Incandescent lamps come in many shapes and sizes. They are used in home and office lighting, as car headlights, and as flashlight bulbs. Incandescent lamps are inexpensive. But they are relatively inefficient because they turn most of the electric energy into heat, rather than light. Incandescent lamps also do not last long. The heat causes some metal in the filament to evaporate. Eventually, a gap forms, and the filament can no longer conduct current.

Halogen lamps are a particular kind of incandescent lamp. A halogen lamp typically has a quartz bulb that holds a small amount of a chemical element from the halogen family, usually bromine or iodine. During operation, the halogen in the bulb combines with evaporated tungsten and forms a gas. When this gas touches the hot filament, it breaks down, redepositing the evaporated tungsten. This process makes the filament last longer. A halogen lamp may last several times longer than a standard incandescent bulb. Halogen lamps also provide more light using less electric power.

Gaseous-discharge lamps

A gaseous-discharge lamp produces light by passing electrical current through a gas. The gas is sealed inside a bulb of glass or another ceramic material. Gaseous-discharge lamps require a strong current to start working, but then must limit the current’s strength during operation. Typically, a device called a ballast regulates the lamp’s current.

The current causes the gas to give off electromagnetic radiation. Visible light is a form of electromagnetic radiation. But some gaseous-discharge lamps give off invisible radiation, which must be changed into visible light. Gaseous-discharge lamps can be divided into two basic kinds: low-pressure lamps and high-pressure lamps.

Low-pressure gaseous discharge lamps

hold the gas at a relatively low pressure. They include fluorescent lamps, a widespread form of indoor lighting. Fluorescent lamps contain a small amount of mercury gas. When current passes through the gas, the mercury atoms ionize (become charged) and give off electromagnetic radiation. Most of this radiation is in the form of ultraviolet light. Such light is beyond the violet end of the visible spectrum and thus cannot be seen by humans.

The inside of a fluorescent lamp bulb is coated with a material called a phosphor. The ultraviolet light strikes the phosphor, which in turn gives off visible light. Fluorescent lamps can produce different colors of light using different phosphor coatings.

Linear fluorescent lamps are long tubes designed to fit into special fixtures. Beginning in the 1940’s, such lamps began replacing incandescent lamps in many buildings. The new lamps were more expensive and required new fixtures, but they cost less to operate and lasted longer. Compact fluorescent lamps (CFL’s) are coiled into traditional light bulb shapes and can fit in the same fixtures that hold incandescent lamps.

The mercury inside a fluorescent lamp is toxic. Thus, the lamps should be handled carefully to avoid breakage. They should also be disposed of in a recycling center. Despite their mercury content, fluorescent lamps actually contribute less mercury pollution to the environment than do incandescent lamps overall. This fact is true because fluorescent lamps use far less electric power, which results in much mercury pollution when generated by coal-burning power plants.

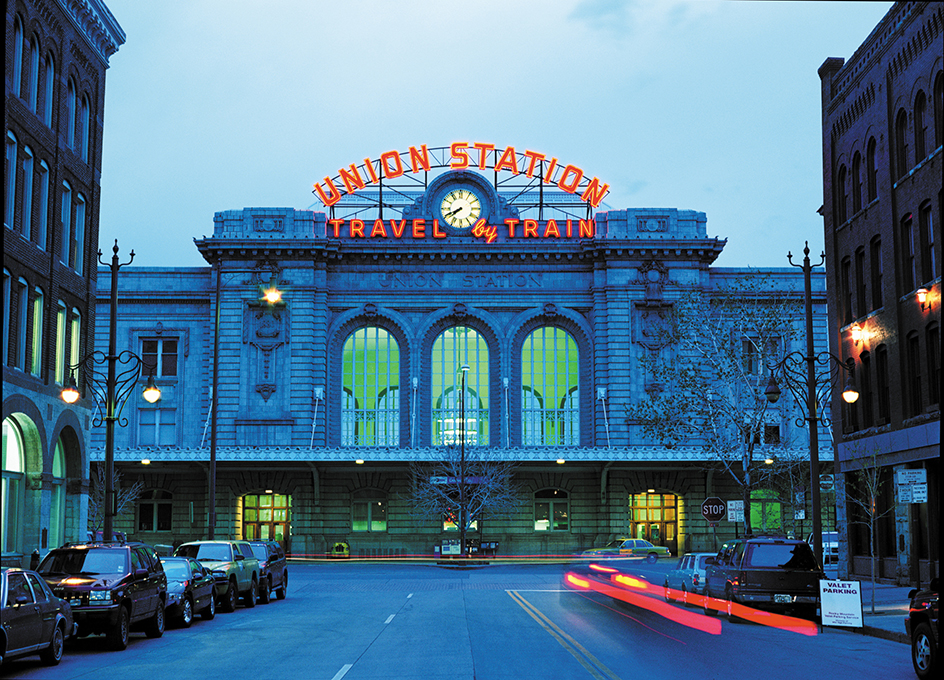

Neon lights are another kind of low-pressure discharge lamp. They contain neon, a harmless gas that produces red-orange light when current runs through it. Neon can be combined with other gases or placed in colored tubes to produce different colors of light.

High-pressure discharge lamps

hold a gas inside the bulb at a much higher pressure than do fluorescent and neon lights. The two most common high-pressure discharge lamps are high-pressure sodium lamps and metal halide lamps. These types of lamps are also called high-intensity discharge (HID) lamps because they produce a great deal of light. They are usually too bright for use inside homes and offices. Instead, they are used primarily for such outdoor applications as street lights or in large warehouses or athletic facilities.

Like fluorescent lamps, HID lamps contain mercury. But additional active chemical compounds are often added to the gas. Under high pressure, HID lamps produce a broad spectrum of light, so they usually do not require phosphors. A device called an arc tube, housed within an outer glass bulb, contains the gas and maintains high pressure in these lamps. Arc tubes are made of various materials that minimize corrosion by chemical compounds. With some exceptions, HID lamps usually take several minutes to build up enough pressure to achieve full brightness. After they have been turned off, HID lamps must cool down before they can restart, which can take several minutes.

High-pressure sodium (HPS) lamps

are extremely efficient. They can last over 20,000 hours and are relatively inexpensive and highly reliable. They typically produce an orange-colored light, however, largely limiting their use to street lighting. They are also commonly used to supplement daylight in greenhouses.

Metal halide (MH) lamps

produce white light. But MH lamps are slightly less efficient than HPS lamps. Over time, the color of an MH lamp often shifts from white to shades of pink or green. For this reason, MH lamps are often replaced before they fail completely. MH lamps are used in outdoor settings. Some are used for automobile headlights, but a special ballast is required to ensure rapid starting.

Solid-state lights

Solid-state lights, much like computer chips, make use of semiconductors. A semiconductor is a material that conducts electric current better than does an insulator, such as plastic, but not as well as does a conductor, such as many metals. The electrical properties of semiconductors enable manufacturers to precisely control the way current flows through them. Most solid-state lights are light-emitting diodes.

Light-emitting diodes (LED’s)

are highly efficient and last an extremely long time. LED’s can be used in a variety of applications, from small colored lights on automobile dashboards to bright street lamps.

LED’s use semiconducting diodes. In a semiconducting diode, electric current flows in one direction between two slightly different materials. The two materials share a special kind of border called a p-n junction. Applying a voltage causes electrons to move from the “n” side of the junction to the “p” side. The p side contains structures that have spaces, or holes, where electrons normally go. The electrons fill the holes, releasing energy in the form of light. For more information, see Electronics.

Different LED materials produce different colors of light. A variety of compounds have been used in LED’s, but they often contain two main types of alloys (mixtures of metals and other materials). Aluminum-gallium-indium phosphide alloys are used for red, orange, and yellow LED’s. Such alloys are abbreviated AlGaInP or AlInGaP. Indium-gallium-nitride (InGaN) alloys are used in green and blue LED’s. Slight changes in the composition of these alloys changes the color of light given off.

White LED light is typically produced by one of two methods. The first method simply combines red, green, and blue LED’s into a single white light source. However, each type of LED responds differently to changes in environment and temperature. Likewise, each type degrades at a different rate. Thus, special control mechanisms are required to maintain a constant white color. The second, and most common, method for producing white light involves combining a blue LED with a phosphor. Much as in a fluorescent lamp, the phosphor absorbs some of the blue light and gives off other colors. The combination of blue light from the LED and the phosphor’s light results in white light.

Organic light-emitting diodes (OLED’s)

work in a way similar to traditional LED’s. But OLED’s consist of thin films containing the element carbon. OLED’s are much more expensive to produce than are LED’s, limiting their use to thin cell phone and television screens.

Measuring efficiency

Electric lights vary widely in luminous efficacy—_that is, how much light they can produce using a given amount of electric power. Luminous efficacy is measured in _lumens per watt. The lumen is a measure of the “amount” of light. The watt is a measure of electric power.

A modern incandescent bulb has a relatively low luminous efficacy, about 10 to 20 lumens per watt. CFL bulbs produce about 40 to 70 lumens per watt, and linear fluorescent bulbs produce about 50 to 100. Household LED’s produce about 50 to 100 lumens per watt.

High-pressure sodium lamps can have an extremely high luminous efficacy—50 to 140 lumens per watt. Metal halide lamps have slightly lower maximum efficacies, about 50 to 110 lumens per watt.

History

Basic electric lights were invented in the early 1800’s. The carbon arc lamp produced light from a current that leapt across a gap between two carbon electrodes (conductors), forming an arc of intense heat and light. It required a high voltage, lasted a short time, and was too bright for most purposes. In the middle to late 1800’s, improved carbon arc lamps were used in outdoor theaters and public squares. But the lamps remained too impractical for indoor use.

Practical indoor incandescent lamps were introduced commercially in the 1880’s. The basic design of incandescent lamps remains the same, but the parts have been continually refined. In the 1900’s, incandescent lamps became widespread in homes, offices, schools, and other buildings.

Loading the player...Thomas Alva Edison

The first mass-produced fluorescent lamp was introduced in 1938. Like incandescent lamps, fluorescent lamps have been continually improved. Today, linear fluorescent lamps serve as the main source of illumination in offices, schools, and factories. Compact fluorescent lamps, introduced commercially in the early 1980’s, are often used in homes. But they have not completely replaced incandescent lamps.

HID light sources, particularly HPS and MH lamps, were developed in the 1960’s and 1970’s. They became the primary light sources for such outdoor public spaces as roads and parking lots.

The first practical LED’s were introduced in the 1960’s. They were red lights used in signals and digital displays. Over the next few decades, researchers developed LED’s that produced other colors. In the 1990’s, engineers developed practical versions of green and blue LED’s, enabling the production of white light. In the 2010’s, LED’s began to widely replace other light sources.