Factory is a building or group of buildings in which products are manufactured. Factories range in size from home garages to groups of buildings covering whole city blocks. Inside, workers and machines turn raw materials into parts and then assemble parts into finished products. Factories, also called plants, employ about one-fourth of the world’s labor force.

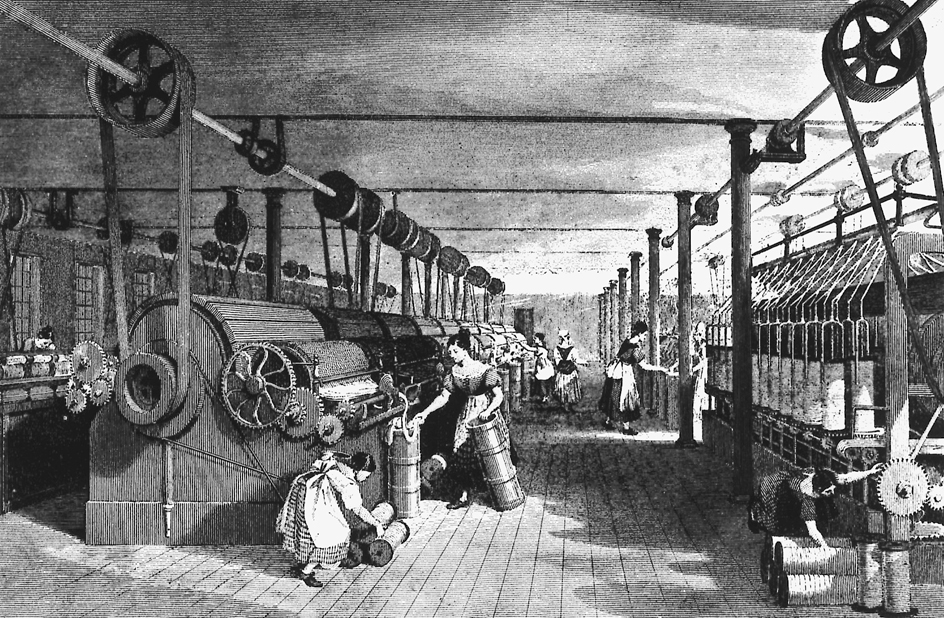

Before the development of factories, workers made most manufactured products in homes or small workshops. The development of power-driven machines in the 1700’s and 1800’s made the modern factory system possible in many countries (see Industrial Revolution).

Kinds of factories.

Factories use the principle of division of labor—that is, they divide the work into a number of separate operations. There are four main manufacturing methods used in factories: (1) repetitive, (2) process, (3) fixed-position, and (4) cellular.

A factory uses repetitive manufacturing to make many units of the same product. Automobile makers use a repetitive approach called the assembly-line method, in which the auto frame moves on a conveyor through the factory. As the frame moves, parts arrive on other conveyors and get attached to the frame.

Process manufacturing is used for a wide variety of products, such as specialized tools or complex mechanical parts that are made to order. Machines are grouped by the types of operations they perform. Each job moves through the factory visiting only the machine groups needed. Skilled operators must set up the machines for each job. Factories that do process manufacturing are often called job shops.

A factory uses fixed-position manufacturing to make only a small number of units of the same product. In aircraft factories, the product cannot be moved because of its size. Instead, workers and equipment must come to the product. Completing one unit may take months.

Cellular manufacturing combines repetitive and process methods. Machines are set up in a linear or U-shaped cell to make a family of similar products. The factory may have many cells, each making a different product family. Cells may be set up to make a certain number of units of a product. Once that number is finished, the cells are changed to make another product.

Location and design.

Manufacturers try to build their factories in areas where land and employees are available at low cost. The chosen locations also must have good access to highways, railroads, or ports to allow for receiving materials and shipping finished products. Many plants have a one-story structure, which permits materials to move easily through them.

Manufacturers often use computers to link factories to customers and suppliers. As customers use products, the factory plans which products to produce and automatically orders the needed materials from suppliers. In many factories, computers control the operations of machines and the flow of work through the plant. The computers enable a few technicians to survey and operate the entire factory efficiently. Such factories may use robots and computer-controlled machine tools to perform complex, tiring, or dangerous tasks.