Gasoline engine is an engine that uses gasoline as a fuel. It is called a petrol engine in the United Kingdom and other countries that use the word petrol to refer to gasoline. Inside a gasoline engine, the combustion (burning) of fuel mixed with air produces hot gases that expand against parts of the engine and cause them to move. For this reason, gasoline engines are called internal-combustion engines. The motion inside the engine is transferred outside to turn wheels and propellers or to operate machines. In this way, a gasoline engine turns chemical energy into mechanical work. The rate at which a gasoline engine produces work is usually measured in horsepower or watts (see Horsepower ).

Gasoline engines are compact and light in weight for the power they produce. This makes them one of the most important types of engines for vehicles. Nearly all automobiles, lawn mowers, motorcycles, motor scooters, snowmobiles, and small tractors have gasoline engines. So do many trucks, buses, airplanes, and small boats. Gasoline engines may also serve as portable power plants—for example, to supply the power to run pumps and other machinery on farms.

Kinds of gasoline engines

There are two main types of gasoline engines, reciprocating engines and rotary engines. Reciprocating engines have pistons that move up and down or back and forth. A part called a crankshaft changes this reciprocating motion into rotary motion. A rotary engine, also known as a Wankel engine, uses devices called rotors instead of pistons. The rotors produce rotary motion directly. This article discusses reciprocating engines, the more common type. For information on rotary engines, see the World Book article on Rotary engine .

Reciprocating gasoline engines are classified in a number of ways. These include (1) by the number of piston strokes per cycle, (2) by the factor by which the fuel and air mixture is compressed, (3) by the way the engines are cooled, (4) by their valve arrangement, (5) by their cylinder arrangement, and (6) by the way they are supplied with air and fuel.

Loading the player...How a two-stroke cycle gasoline engine works

Cycle.

Most reciprocating gasoline engines operate on either a two-stroke or a four-stroke cycle. Cycle refers to the steps that must be repeated for each combustion of the fuel-air mixture in the cylinders. A stroke is a movement of a piston in one direction. A four-stroke engine has intake, compression, power, and exhaust strokes. A two-stroke engine combines the exhaust and intake steps near the end of the power stroke. Although two-stroke engines are less fuel-efficient and produce more pollution than four-stroke engines, they are generally simpler and cheaper to build. A two-stroke engine is used where low cost is important, as in a power lawn mower. In some applications, it delivers more power for a given weight and size than does a four-stroke engine. Each cylinder in a two-stroke engine produces a power stroke for every turn of the crankshaft. But in a four-stroke engine, a cylinder produces a power stroke on every other rotation.

Loading the player...How a four-stroke cycle gasoline engine works

High and low compression.

As a piston moves from the bottom to the top of a cylinder, it compresses the air and gasoline mixture. A number, called the compression ratio, tells how much the mixture is compressed. A high-compression engine may have a compression ratio of 10 to 1. Such an engine compresses the mixture to a tenth of its original volume. A low-compression engine may have a ratio of 8 to 1. High-compression engines produce more work per unit of air-fuel mixture than do low-compression engines. However, they also produce higher combustion temperatures. As these temperatures increase, so does the emission of the pollutant nitrogen oxide. High-compression engines require high-octane gasoline to run smoothly. Octane number is a measure of how smoothly fuel burns in an engine (see Octane number ).

Cooling.

The burning fuel-air mixture in a cylinder produces gas temperatures of about 4500 °F (2500 °C). Therefore, the metal parts of the engine must be cooled or they would melt. Most automotive gasoline engines are liquid cooled. A liquid, usually water, is circulated around the cylinders to cool the metal. The heated liquid is then pumped through a radiator. A fan driven by the engine or by an electric motor draws air through the radiator to cool the liquid.

Most aircraft gasoline engines in small planes are air cooled to reduce weight. Air is not as effective a coolant as liquids, so the outside of the cylinders has many fins. These fins conduct heat from the cylinder and provide a large surface area over which air can sweep.

Valve arrangement.

The two most common valve arrangements are (1) L-head and (2) I-head. An L-head, or underhead, valve engine has the intake and exhaust valves side by side in the cylinder block. The intake valve admits the air-fuel mixture into the cylinder, and the exhaust valve lets out the exhaust gases. An I-head, or overhead, valve engine has the valves side by side in the cylinder head, the cylinder block’s top cover. In some cars, each cylinder has four valves—two intake valves and two exhaust valves.

Cylinder arrangement.

Engines are also classified by the number and arrangement of cylinders. The most common types include in-line, V, radial, and horizontal opposed. Radial engines have an odd number of cylinders, such as three, five, seven, or nine. Most other engines have an even number of cylinders—4, 6, 8, or 12.

Air and fuel.

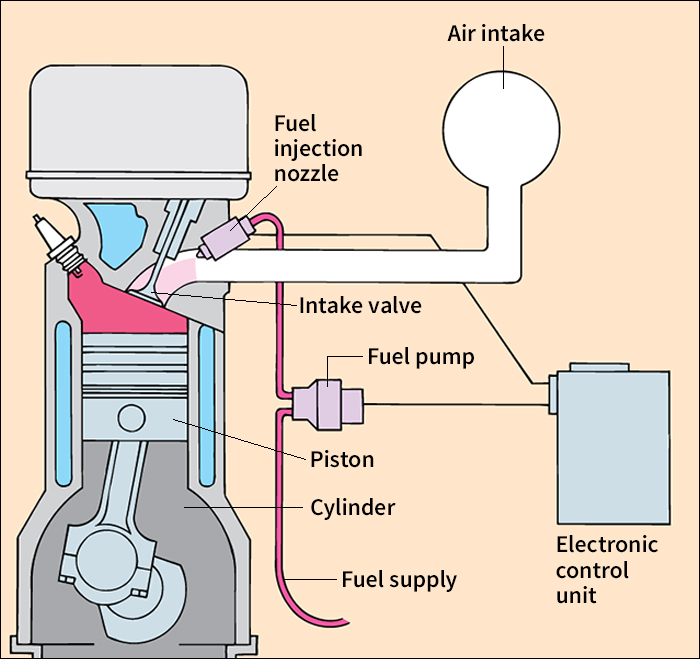

Fuel may be metered, or sent, to the cylinders by either an injection system or a carburetor. Therefore, reciprocating engines are also classified as either fuel-injected or carbureted engines (see Carburetor ; Fuel injection ). Combustion depends upon both air and fuel. The mass of air needed to burn 1 unit of gasoline weighs approximately 15 times as much as the gasoline. The power of an engine is limited by the amount of air that can reach the cylinder. To increase power, an engine may be supercharged or turbocharged. A supercharger is an engine-driven pump, and a turbocharger is an exhaust-driven pump. Both pumps force extra air into the cylinders, increasing the engine power.

Parts of a reciprocating gasoline engine

The cylinder block

is a rigid frame that holds the cylinders in proper alignment. If the engine is liquid cooled, the block is jacketed—that is, it has passages for the liquid around each cylinder. In automotive engines, the cylinder block and crankcase form a single unit. Most cylinder blocks are cast from iron, iron alloys, or aluminum.

The cylinders

are rigid tubes within which the pistons move up and down. The cylinders and pistons have highly polished surfaces that permit a close fit between piston and cylinder. The tight fit prevents gases from leaking past the piston. The cylinders in most automobile engines are part of the block. Some engines have a cylinder sleeve made of specially hardened steel or cast iron pressed into the cylinder block.

The cylinder head

is a casting bolted to the top of the cylinder block. The cylinder head, together with the upper end of the cylinder and the top of the piston, form the combustion chamber, in which the fuel-air mixture burns. A cylinder head and block may be one unit.

The crankcase

is a rigid frame that holds the crankshaft and the crankshaft bearings. In small engines, all or part of the crankcase may be a part of the cylinder block.

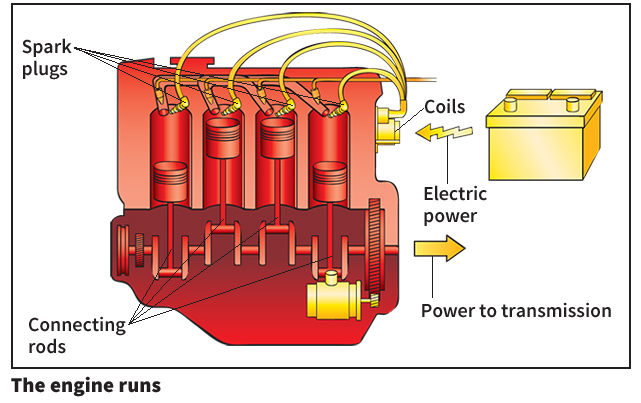

The pistons and connecting rods.

When the fuel-air mixture burns, the expanding gases exert a force on the piston. This force is then transmitted to the crankshaft through a connecting rod. The piston has two to six rings to prevent the gases from escaping past the piston and to keep lubricating oil from getting into the combustion chamber.

The crankshaft

changes the reciprocating motion of the pistons into rotary motion. The crankshaft has a number of cranks, or throws. These cranks are displaced at angles to each other. For example, in a six-cylinder, in-line, four-stroke engine, the cranks are displaced at 120° angles to each other. Thus, the engine delivers three equally spaced power strokes in each revolution of the crankshaft, resulting in smooth operation.

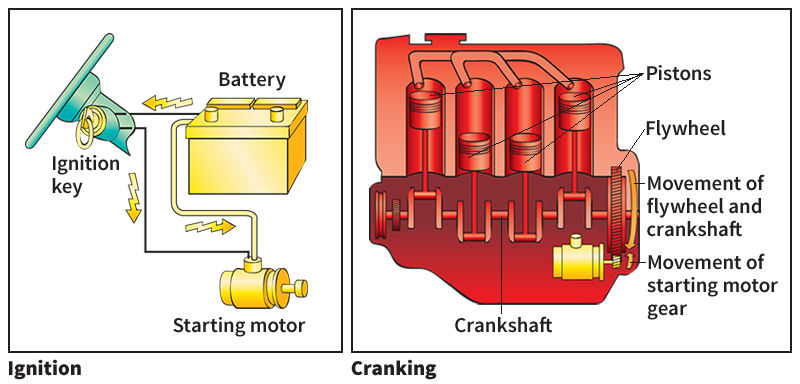

The flywheel

uses inertia, a moving object’s resistance to any change in its motion, to turn the crankshaft at a nearly constant speed. Energy absorbed by the flywheel during a piston’s power stroke is released during the other strokes (see Flywheel ).

The valves.

In a four-stroke engine, each cylinder has one or two intake valves to let the air-fuel mixture into the combustion chamber, and one or two exhaust valves to let the burned gases escape. These are called poppet valves, because they pop up and down as they open and close. The opening in the cylinder block or head uncovered by the valve is called the port. In many two-stroke engines, the movement of the piston takes the place of separate valves. As the piston moves, it covers and uncovers the ports.

The camshaft

runs the length of the engine and has one cam (lobe) at each intake and exhaust valve. The cams open and close the valves at the proper point in the engine cycle. In a four-stroke engine, the camshaft is geared to the crankshaft so that it runs at half the crankshaft’s speed. The camshaft may be in the head of an overhead valve engine, or in the crankcase.

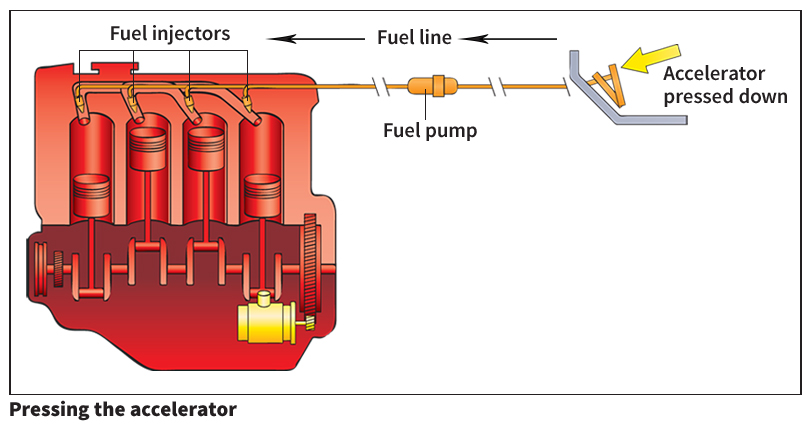

The fuel system

generally includes (1) a storage tank, (2) fuel lines, and (3) a fuel injection system. The storage tank holds gasoline. The fuel lines carry the gasoline to the fuel injection system, which injects the gasoline into air and distributes the fuel-air mixture to the cylinders. The fuel injection system also includes a fuel pump to push the fuel from the tank to the injector and a gasoline filter to clean dirt from the fuel. The air system includes an air cleaner to take dirt out of the air that is mixed with the gasoline. See Fuel injection .

Some engines, especially smaller or older ones, have a carburetor instead of a fuel injection system. This device mixes fuel with air. An intake manifold distributes the fuel-air mixture to the cylinders. See Carburetor .

The exhaust system

consists of one or more parts. It may include (1) an exhaust manifold to collect the burned gases from the cylinders, (2) an exhaust pipe to carry the burned gases, (3) a catalytic converter to remove exhaust pollutants, and (4) a muffler to silence the noise of the exhaust gases. See Muffler .

The ignition system

is the electrical circuit necessary to ignite (set fire to) the fuel-air mixture in the different cylinders at different times. In an automobile, a storage battery provides electric current, which is increased in voltage by an induction coil. In some cars, the high-voltage current is carried through a distributor, which delivers the electric power to each cylinder at about the same time that the piston reaches the top of the compression stroke. There, the electric current jumps a gap between the two terminals of a spark plug and sets fire to the fuel-air mixture. See Battery ; Ignition .

Most automobile engines manufactured since the mid-1980’s have an electronic ignition system. Such a system uses electronic parts, such as capacitors and transistors, to produce the ignition voltage and to control it. Electronic ignition systems may use a distributor to deliver the electric power to each cylinder, or the electric power may be delivered directly to the cylinders. Electronic systems require less maintenance than do older systems, and they provide better performance.

In an airplane engine, the high-voltage electric current may be generated by a magneto and carried to the spark plugs. A magneto does not require a battery to operate. See Magneto .

The lubrication system

provides oil as a film between the moving parts of the engine to prevent wear from friction and to keep the engine cool. The two common types of four-stroke engine lubrication systems are the wet sump and the dry sump. In a wet-sump engine, the oil supply is contained within the engine, in the bottom of the crankcase. In a dry-sump engine, the oil supply is held in a separate oil tank.

Some two-stroke engines, such as those used on lawn mowers, motorcycles, and boats, have no separate lubrication system. Users of these engines mix a small amount of lubricating oil with the gasoline. Larger heavy-duty two-stroke engines have lubrication systems similar to those on four-stroke engines.

Development of the gasoline engine

Early internal-combustion engines used gases instead of gasoline as fuel. William Cecil, an English clergyman, invented what is believed to be the earliest working gas engine in 1820. That year, Cecil read a paper to the Cambridge Philosophical Society describing an engine driven by the explosion of a mixture of hydrogen and air. He also demonstrated a working model of the engine.

Another English inventor, William Barnett, in 1838 patented a gas engine that compressed the fuel mixture. Barnett’s engine had a single up-and-down cylinder with combustion occurring first at the top, then at the bottom, of the piston.

In France, Jean Joseph Étienne Lenoir patented the first practical internal-combustion engine in 1860. It used coke oven gas for fuel. This single-cylinder engine had a storage-battery ignition system. By 1865, about 500 of these engines were used to power such equipment as printing presses, lathes, and water pumps. Lenoir also installed his engines in a motor vehicle and a boat.

In 1862, another Frenchman, Alphonse Beau de Rochas, worked out on paper the idea of the four-stroke engine. But he did not build one. Four years later, Nikolaus August Otto and Eugen Langen of Germany built a successful four-stroke gas engine. In 1876, they obtained patents in the United States on both two- and four-stroke gas engines.

The first successful four-stroke engine to burn gasoline was designed in 1885 by Gottlieb Daimler, a German engineer. In the same year, Karl Benz, another German, also developed a successful gasoline engine. These engines were fundamentally the same as gasoline engines built today. For later development of the gasoline engine, see Automobile .

Air pollution controls

Gasoline engines produce certain air pollutants. Most industrialized countries have set legal limits on the amount of pollutants automobiles and other road vehicles may produce. In the United States, the Clean Air Act, along with its amendments, establishes these limits. The amendments include emission regulations for off-road vehicles and small engines as well as for road vehicles. The Environmental Protection Agency (EPA) enforces the act and its amendments.

Since the 1970’s, automakers have made a number of modifications in engine design to reduce harmful emissions. Most cars made since that time have catalytic converters. Automobiles with electronic engine control have a device called an oxygen sensor in the exhaust system. This sensor signals the electronic engine control to adjust the fuel-air mixture for the most effective operation of the catalytic converter. See Automobile (The exhaust system) .

The amount of carbon dioxide emitted from engines may also be harmful. Carbon dioxide is a greenhouse gas, a gas that traps heat in the atmosphere. Because carbon dioxide is a desired product of successful combustion, the only way to reduce its emission is to reduce fuel consumption.