Glass is one of the most useful materials in the world. Few manufactured substances add as much to modern living as does glass. Yet few products are made of such inexpensive raw materials. Glass is made chiefly from silica sand (silica, also called silicon dioxide), soda ash (sodium carbonate), and limestone (calcium carbonate).

Glass has countless uses. Food is preserved in glass jars. People drink from glass containers called glasses. Windows in homes, schools, and office buildings are glass. Motor vehicles have glass windshields and windows. People with vision problems wear eyeglasses. Scientists use glass test tubes, and microscopes and telescopes with glass lenses. Glass optical fibers carry data all over the world at the speed of light over the Internet, the worldwide network of computers.

Besides being useful, glass is also ornamental. Ever since people learned how to make glass, they have used it as an art material.

Glass can take many different forms. It can be spun finer than a spider web. Or it can be molded into a disk for a telescope lens or mirror weighing many tons. Glass can be stronger than steel, or more fragile than paper. Most glass is transparent, but glass can also be colored to any desired shade.

Most countries of the world have glass industries. For many years, Germany was the major world source for optical glass, laboratory glassware, and glass Christmas tree ornaments. Today, glass manufacturers in many countries produce such objects on a large scale. Beautiful art glassware is made in many countries, including the Czech Republic, France, Ireland, Italy, and Sweden.

Major glass companies spend millions of dollars each year on research to discover ways to make better glass and to develop new uses for glass. Many of the revolutionary developments in glass during the 1900’s have come from the laboratories of glass manufacturers.

Kinds of glass

When people speak of glass, they ordinarily mean a transparent, shiny substance that breaks rather easily. They may think of the glass in windows and the glass used in eyeglasses as being the same material. Actually, they are not. There are many kinds of glass. Several important kinds of glass are discussed in this article.

Flat glass

is used chiefly in windows. It is also used in mirrors, room dividers, and some kinds of furniture. All flat glass is made in the form of flat sheets. But some of it, such as that used in automobile windshields, is reheated and sagged (curved) over molds.

Glass containers

are used for packaging food, beverages, medicines, chemicals, and cosmetics. Glass jars and bottles are made in a wide variety of shapes, sizes, and colors. Many are for common uses, such as soft-drink bottles or jars for home canning. Others are made from special glass formulas to make sure there will be no contamination or deterioration of blood plasma, serums, and chemicals stored in them. See Bottle.

Optical glass

is used in eyeglasses, microscopes, telescopes, camera lenses, and many instruments for factories and laboratories. The raw materials must be pure so that the glass can be made almost flawless. The care required for producing optical glass makes it expensive compared with other kinds of glass. See Glasses; Lens; Microscope; Telescope.

Fiberglass

consists of fine but solid rods of glass, each of which may be less than one-twentieth the width of a human hair. These tiny glass fibers can be loosely packed together in a woollike mass that can serve as heat insulation. They also can be used like wool or cotton fibers to make glass yarn, tape, cloth, and mats. Fiberglass has many other uses. It is used for electrical insulation, chemical filtration, and firefighters’ suits. Combined with plastics, fiberglass can be used for airplane wings and bodies, automobile bodies, and boat hulls. Fiberglass is a popular curtain material because it is fire-resistant and washable. See Fiberglass.

Specialty glasses

are all other types of glass besides flat glass, glass containers, optical glass, and fiberglass. Below are descriptions of 22 important specialty glasses.

Laminated safety glass

is a “sandwich” made by combining alternate layers of flat glass and plastics. The outside layer of glass may break when struck by an object, but the plastic layer is elastic and so it stretches. The plastic holds the broken pieces of glass together and keeps them from flying in all directions. Laminated glass is used where broken glass might cause serious injuries, as in automobile windshields.

Bullet-resisting glass

is thick, multilayer laminated glass. This glass can stop even heavy-caliber bullets at close range. Bullet-resisting glass is heavy enough to absorb the energy of the bullet, and the several plastic layers hold the shattered fragments together. Such glass is used in bank teller windows and in windshields for military tanks, aircraft, and special automobiles.

Tempered safety glass,

unlike laminated glass, is a single piece that has been given a special heat treatment. It looks, feels, and weighs the same as ordinary glass. But it can be several times stronger. Tempered glass is used widely for all-glass doors in stores, side and rear windows of automobiles, and basketball backboards, and for other special purposes. It is hard to break even when hit with a hammer. When it does break, the whole piece of glass collapses into small, dull-edged fragments.

Colored structural glass

is a heavy plate glass, available in many colors. It is used in buildings as an exterior facing, and for interior walls, partitions, and tabletops.

Opal glass

has small particles in the body of the glass that disperse the light passing through it, making the glass appear milky. The ingredients necessary to produce opal glass include fluorides (chemical compounds containing fluorine). This glass is widely used in lighting fixtures and for tableware.

Foam glass,

when it is cut, looks like a black honeycomb. It is filled with many tiny cells of gas. Each cell is surrounded and sealed off from the others by thin walls of glass. Foam glass is so light that it floats on water. It is widely used as a heat insulator in buildings, on steam pipes, and on chemical equipment. Foam glass can be cut into various shapes with a saw.

Glass building blocks

are made from two hollow half-sections sealed together at a high temperature. Glass building blocks are good insulators against heat or cold because of the dead-air space inside. The blocks are laid like bricks to make walls and other structures.

Heat-resistant glass

is high in silica and usually contains boric oxide. It expands little when heated, so it can withstand great temperature changes without cracking. This quality is necessary in cookware and other household equipment, and in many types of industrial gear.

Laboratory glassware

includes beakers, flasks, test tubes, and special chemical apparatus. It is made from heat-resistant glass to withstand severe heat shock (rapid change in temperature). This glass is also much more resistant to chemical attack than ordinary glass.

Glass for electrical uses.

Glass has properties that make it useful in electrical applications: ability to resist heat, resistance to the flow of electric current, and ability to seal tightly to metals without cracking. Because of these properties, glass is used in electric light bulbs and for picture tubes in television sets.

Glass optical fibers

are glass fibers used to transmit information as pulses of light. Thin, extremely pure optical fibers are used to carry telephone and television signals and digital (numeric) data over long distances. Glass optical fibers are also used in control board displays and in medical instruments. See Fiber optics.

Glass tubing

is used to make fluorescent lights, neon signs, glass piping, and chemical apparatus. Glass tubing is made from many kinds of glass and in many sizes.

Glass-ceramics

are strong materials made by heating glass to rearrange some of its atoms into regular patterns. These partially crystalline materials can withstand high temperatures, sudden changes in temperature, and chemical attacks better than ordinary glass can. They are used in a variety of products, including heat-resistant cookware, turbine engines, electronic equipment, and nose cones of guided missiles. Glass-ceramics have such trade names as Pyroceram, Cervit, and Hercuvit.

Radiation-absorbing and radiation-transmitting glass

can transmit, modify, or block heat, light, X rays, and other types of radiant energy. For example, ultraviolet glass absorbs the ultraviolet rays of the sun but transmits visible light. Other glass transmits heat rays freely but passes little visible light. Polarized glass cuts out the glare of brilliant light. One-way glass is specially coated so that a person can look through a window without being seen from the other side. See Polarized light.

Laser glass

is an optical glass containing small amounts of substances that enable the glass to generate laser beams efficiently. Such glass is used as the active medium in solid-state lasers, a type of laser that sends light out through crystals or glass (see Laser (Solid-state lasers)). One substance commonly used in laser glass is the element neodymium. Researchers are using glass lasers in an attempt to harness nuclear fusion (the joining of atomic nuclei) as a source of commercially useful amounts of energy. In their experiments, powerful glass lasers heat hydrogen atoms until hydrogen nuclei fuse, releasing large amounts of energy.

“Invisible glass”

is used principally for coated camera lenses and eyeglasses. The coating is a chemical film that decreases the normal loss of light by reflection. This allows more light to pass through the glass.

Photochromic glass

darkens when exposed to ultraviolet rays and clears up when the rays are removed. Photochromic glass is used for windows, sunglasses, and instrument controls.

Photosensitive glass

can be exposed to ultraviolet light and to heat so that any pattern or photograph can be reproduced within the body of the glass itself. Because the photographic print then becomes an actual part of the glass, it will last as long as the glass itself.

Photochemical glass

is a special composition of photosensitive glass that can be cut by acid. Any design can be reproduced on the glass from a photographic film. Then when the glass is dipped in acid, the exposed areas are eaten away, leaving the design in the glass in three dimensions. By this means, lacelike glass patterns can be made.

Heavy metal fluoride glass

is an extremely transparent glass being developed for use in optical fibers that transmit infrared rays. Infrared rays are much like light waves but are invisible to the human eye. In optical fibers, infrared light transmits better over distance than visible light does.

Chalcogenide glass

is made up of elements from the chalcogen group, including selenium, sulfur, and tellurium. The glass is transparent to infrared light and is useful as a semiconductor in some electronic devices. Chalcogenide glass fibers are a component of devices used to perform laser surgery.

Sol-Gel glass

can be used as a protective coating on certain solar collectors or as an insulating material. It is also used to make short, thick tubes that are drawn into optical fibers. To make Sol-Gel glass, workers dissolve the ingredients in a liquid. They then heat the liquid. The liquid evaporates, leaving behind small particles of glass. Heating these particles fuses (joins) them to form a solid piece of glass. The temperatures involved in Sol-Gel processes are often lower than those needed to make ordinary glass.

Composition of glass

Glass can be generally divided into two groups: oxide glass and non-oxide glass. The ingredients of oxide glasses include oxides (chemical compounds that include oxygen). Non-oxide glasses are made from compounds that contain no oxides, and which often instead contain sulfides or metals. Oxide glasses are much more widely used commercially. The common types of glass discussed below are all oxide glasses.

Soda-lime glass

is the kind of glass used for flat glass, most containers and electric light bulbs, and many other industrial and art objects. More than 90 percent of all glass is soda-lime glass. It has been made of almost the same materials for hundreds of years. The composition is about 72 percent silica (from sand), about 13 percent sodium oxide (from soda ash), about 11 percent calcium oxide (from limestone), and about 4 percent minor ingredients. Soda-lime glass is inexpensive, easy to melt and shape, and reasonably strong.

All glass container manufacturers use the same basic soda-lime composition, making the containers easy to recycle. Manufacturers sort the glass by color and then later reuse it in the production of new containers.

Soda-lead glass,

commonly called crystal or lead glass, is made by substituting lead oxide for calcium oxide and often for part of the silica used in soda-lime glass. Soda-lead glass is easy to melt. It is much more expensive than soda-lime glass. Soda-lead glass has such beautiful optical properties that it is widely used for the finest tableware and art objects. In addition, lead oxide improves the electrical properties of glass.

Borosilicate glass

is heat-shock resistant and better known by such trade names as Pyrex and Kimax. It contains about 80 percent silica, 4 percent sodium oxide, 2 percent alumina, and 13 percent boric oxide. Such glass is about three times as heat-shock resistant as soda-lime glass and is excellent for chemical and electrical uses. This glass makes possible such products as ovenware and beakers, test tubes, and other laboratory equipment.

Fused silica glass

glass is a highly heat-shock resistant glass that consists entirely of silica. It can be heated to extremely high temperatures and then plunged into ice-cold water without cracking. Fused silica is expensive because exceptionally high temperatures must be maintained during production. It is used in laboratory glassware and optical fibers.

96 percent silica glass

resists heat almost as well as fused silica, but it is less expensive to produce. It consists of a special borosilicate composition that has been made porous by chemical treatment. The pores shrink when the glass is heated, leaving a smooth, transparent surface. The glass is sold under the trade name Vycor.

Colored glass

gets its coloring from certain oxides that are added to the glass. For example, 1 part of nickel oxide in 50,000 produces a tint that may range from yellow to purple, depending on the base glass. One part of cobalt oxide in 10,000 gives an intense blue. Red glasses are made with gold, copper, or selenium oxides. Other colors can be produced in glass with other chemicals.

How glass is made

No other kind of factory looks like a glass plant. Huge bins called silos hold the raw materials for glassmaking. These materials are powders that look much alike but can produce greatly different results. Giant roof ventilators and huge stacks release the terrific heat required to melt these powders to a white-hot liquid. At the hot end of the plant are the furnaces.

Mixing.

The principal raw materials come to the glass plant in railroad cars and are stored in large silos. The materials are carefully weighed and mechanically mixed in the proper proportions. The mix of ingredients is called the batch. The manufacturer then adds cullet to the batch. Cullet is either recycled glass or waste glass from a previous melt of the same kind of glass. Adding cullet to the batch uses materials that otherwise would be wasted. It also reduces the amount of heat needed to melt the new batch of raw materials. Sometimes, glassmakers produce a new batch entirely from cullet. After mixing, the batch goes to the furnaces in batch cars, in hoppers, or on conveyor belts.

Melting.

The mixture melts at 2600 to 2900 °F (1425 to 1600 °C), depending on its composition. In early times, the batch was melted in refractory pots (small clay pots) that were generally heated by wood fires. Special refractory pots today hold up to 3,000 pounds (1,400 kilograms) of glass. They are heated by gas or oil, and a single furnace may contain 6 to 12 pots. Small quantities of optical glass, art glass, and specialty glass still are made in refractory pots.

Larger quantities of glass are made in furnaces that are called day tanks because the process that goes on in them takes about 24 hours. The day tank is filled with raw materials, the glass is melted, and all the glass is used before the furnace is filled again. Day tanks can hold 1 to 4 tons (0.9 to 3.6 metric tons) of glass.

Most glass is melted in large furnaces called continuous tanks. The largest continuous tanks can melt 400 to 600 tons (360 to 540 metric tons) a day for production of flat glass. From 50 to 300 tons (45 to 270 metric tons) of container glass can be melted daily. Smaller continuous tanks are used to produce most other glass products. The operation is continuous. Raw materials are fed into the loading end as rapidly as molten glass is removed from the working end. Loading, melting, and working go on from when the fires are first lighted until they are extinguished at the end of a period called a campaign. A campaign may last as long as 10 years. The length of a campaign is almost always determined by the time it takes the refractory brick walls of the furnace to wear out from the constant heat and friction of the glass.

How glass is shaped and finished

There are four main methods of shaping glass: blowing, pressing, drawing, and casting. After the shaping process, annealing is used to increase the strength of the glass. Tempering and other finishing techniques may also be used to further strengthen the glass. At the cold end of the plant, finished glass products are inspected and boxed for sale. The glass may also be decorated before packaging. See the section How glass is decorated later in this article.

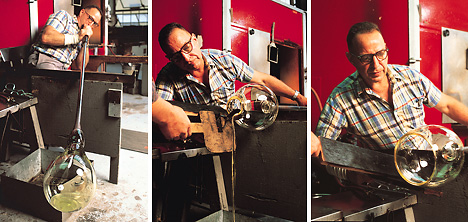

Blowing.

Offhand glass blowing (blowing glass without the use of molds) is an art about 2,000 years old. A hollow iron blowpipe, 4 to 5 feet (1.2 to 1.5 meters) long, is dipped in molten glass, some of which sticks to the pear-shaped end of the pipe. A worker blows gently into the pipe until the glass bulges out and forms a hollow bulb. The bulb can be squeezed, stretched, twirled, and cut. From time to time, the worker reheats the glass to keep it soft. When the red-hot glass has been given its final shape, it is removed from the pipe. Glass can also be blown into iron molds—by hand or by machine.

Pressing

is accomplished by dropping a hot gob of glass into a mold, then pressing it with a plunger until it spreads and fills the inside of the mold. To be pressed, an article must be of such a shape that the plunger can be withdrawn. Baking dishes, glass blocks, and lenses are often pressed. As with blowing, pressing can be done by hand or by machine, and with single or multiple molds. Press-and-blow machines use a combination of the pressing and the blowing methods to form the article. Such machines can produce hundreds of glass containers per hour.

Drawing

is the method used for shaping flat glass, glass rod, glass tubing, and fiberglass. Almost all flat glass produced today is float glass. It is shaped by drawing a wide sheet of molten glass into a furnace containing a bath of molten tin. This furnace is called a float bath because the glass “floats” in an even layer on the perfectly smooth surface of the molten tin. Heating in the float bath is carefully controlled to melt out any roughness in the glass. Because glass turns solid at a higher temperature than tin, it can be moved from the molten tin for further cooling. When flat glass is shaped in a float bath, both sides come out with a brilliant finish that requires no grinding or polishing.

Glass rod is made by drawing a stream of molten glass out of the furnace. Tubing is made by drawing the molten glass around a rotating cylinder or cone called a mandrel. Air blowing through the mandrel causes the glass to form a continuous tube. Fiberglass is made by drawing the molten glass through tiny holes in the bottom of the furnace.

Casting

involves filling molds with molten glass. The glass may be poured either from ladles or directly from the furnace, or drained from the bottom of the furnace. Casting is used in the production of architectural glass pieces, art glass, laser glass, and telescope mirrors.

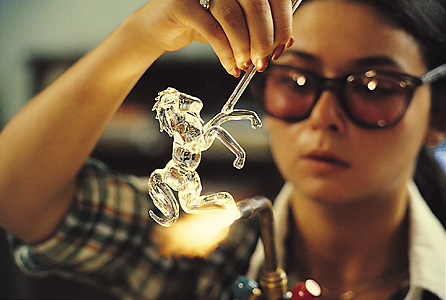

Lampworking

is a method of reshaping solid glass into new forms by reheating it. Lampworkers reheat various kinds and sizes of glass tubing and rod over a blowtorch fired by gas and oxygen. Then they can bend, twist, stretch, and seal the softened glass into a variety of objects. In this way, lampworkers make miniature animals, vases, sailing ships, beads, scientific equipment, and parts for incandescent lamps and various kinds of industrial equipment. Lampworkers produce many small parts for the electrical, chemical, and medical industries on high-speed automatic machines by reworking the softened glass.

Annealing

is a process that removes the stresses and strains remaining in glass after shaping. Most glassware is annealed just after it has been formed. If it is not annealed, glass may shatter from tension caused by uneven cooling. Annealing is done by reheating the glass and gradually cooling it according to a planned time-and-temperature schedule. See Annealing.

Tempering

is a process in which a glass article that is already formed is reheated until almost soft. Then, under carefully controlled conditions, it is chilled suddenly by blasts of cold air or by plunging it in oil or certain chemicals in a liquid state. This tempering treatment makes the glass much stronger than ordinary glass. Glass articles can also be tempered with chemicals.

Inspection.

In almost every glass plant, engineers take frequent samples directly from the furnace and test them for quality and desired properties. Samples of finished glass products also are tested for size, proper annealing, and other qualities.

How glass is decorated

Several preliminary finishing operations are often necessary before glass articles can be decorated. Excess glass must be removed from blown items. In hand operations, the glass is cut off while it is still soft. Sometimes the glass piece is revolved in front of an intensely hot gas flame. The sudden expansion of the hot, narrow band of glass revolving opposite the flame makes it break off from the cooler glass next to it. In other cases, the item may be supported upside down while even hotter flames are applied until the glass melts and separates. The weight of the extra glass makes it drop into a cullet bin, from which it is returned to the furnace to be used again. The extra glass also can be cut off by scoring (cutting) the glass piece with a diamond or steel wheel, and then snapping off the excess glass with sudden pressure. If the severed (cut) edges of the glass article are not smooth enough, they may be polished with fine abrasives, or by flames in a fire-polishing machine.

Etching.

Hydrofluoric acid and some of its compounds readily dissolve glass. Glass articles dipped in, or sprayed with, these chemicals are said to be etched. The finish of an etched-glass surface depends on the glass composition, concentration of fluorides, and time. The surface may be rough, frosted, and almost opaque; or it may have a translucent, soft, satiny-smooth appearance. The interiors of electric light bulbs are frosted with this satiny finish. Pitchers, water tumblers, and art glass often are etched with intricate designs. They are first painted with a resist (acid-resistant chemical) to protect the parts of the glass outside the desired pattern. Then acid eats away the unpainted surface of the glass, leaving the pattern. A brilliant acid polish can be made by combining hydrofluoric and sulfuric acid.

Sandblasting

gives glass a translucent surface, which is usually rougher than that obtained by etching. Compressed air blows coarse, rough-grained sand against the glass, often through a rubber stencil, to form a design. The labels on glass laboratory equipment are often sandblasted. Lighting devices, ovenware, and plate and window glass are frequently decorated or made translucent by sandblasting.

Cutting

involves wearing away considerable quantities of the original glass by holding it against revolving sandstone or carborundum wheels. The worker follows a design previously marked on the article. The cuts may be quite deep. The original luster is restored to the cut surfaces by etching or by polishing with fine abrasives.

Copper-wheel engraving

can be used to create delicate, detailed, and flowing designs, faithfully reproduced in three dimensions. Many masterpieces in glass are engraved. The process involves the careful cutting of glass with dozens of abrasive-fed copper wheels.

Fired decorations.

Colored enamels and lusters can be applied to glass by hand painting, by decalomania (the process of transferring decals), or by the silk-screen printing process. When these decorations are heated to the proper temperature, they fuse to the glass and thus become part of the article. Tumblers, jugs, pitchers, lighting devices, novelties, and many other glass products are decorated in this way. See Decal; Enamel; Screen printing.

History of glass

Early times.

Before people learned to make glass, they had found two forms of natural glass. When lightning strikes sand, the heat sometimes fuses the sand into long, slender glass tubes called fulgurites, which are commonly called petrified lightning. The terrific heat of a volcanic eruption also sometimes fuses rocks and sand into a glass called obsidian. In early times, people shaped obsidian into knives, arrowheads, jewelry, and money. See Obsidian.

We do not know exactly when, where, or how people first learned to make glass. It is generally believed that the first manufactured glass was in the form of a glaze on ceramic vessels, about 3000 B.C. The first glass vessels were produced about 1500 B.C. in Egypt and Mesopotamia. The glass industry was extremely successful for the next 300 years, and then declined. It was revived in Mesopotamia in the 700’s B.C. and in Egypt in the 500’s B.C. For the next 500 years, Egypt, Syria, and the other countries along the eastern shore of the Mediterranean Sea were glassmaking centers.

Early glassmaking was slow and costly, and it required hard work. Glass blowing and glass pressing were unknown, furnaces were small, the clay pots were of poor quality, and the heat was hardly sufficient for melting. But glassmakers eventually learned how to make colored glass jewelry, cosmetics cases, and tiny jugs and jars. People who could afford them—the priests and the ruling classes—considered glass objects as valuable as jewels. Soon merchants learned that wines, honey, and oils could be carried and preserved far better in glass than in wood or clay containers.

The blowpipe was invented about 30 B.C., probably along the eastern Mediterranean coast. This invention made glass production easier, faster, and cheaper. As a result, glass became available to the common people for the first time. Glass manufacture became important in all countries under Roman rule. In fact, the first four centuries of the Christian Era may justly be called the First Golden Age of Glass. The glassmakers of this time knew how to make a transparent glass, and they did offhand glass blowing, painting, and gilding (application of gold leaf). They knew how to build up layers of glass of different colors and then cut out designs in high relief. The celebrated Portland vase, which was probably made in Rome about the beginning of the Christian Era, is an excellent example of this art. This vase is considered one of the most valuable glass art objects in the world.

The Middle Ages.

Little is known about the glass industry between the decline of the Roman Empire and the 1200’s. Glass manufacture had developed in Venice by the time of the Crusades (A.D. 1096-1500’s), and by the 1290’s an elaborate guild system of glassworkers had been set up. Equipment was transferred to the Venetian island of Murano, and the Second Golden Age of Glass began. Venetian glass blowers created some of the most delicate and graceful glass the world has ever seen. They perfected Cristallo glass, a nearly colorless, transparent glass, which could be blown to extreme thinness in almost any shape. From Cristallo, they made intricate lacework patterns in goblets, jars, bowls, cups, and vases. In the 1100’s and 1200’s, the art of making stained-glass windows reached its height throughout Europe.

By the late 1400’s and early 1500’s, glassmaking had become important in Germany and other northern European countries. Manufacturers there chiefly produced containers and drinking vessels. Northern forms were heavier, sturdier, and less clear than Venice’s Cristallo. During the late 1500’s, many Venetians went to northern Europe, hoping to earn a better living. They established factories there and made glass in the Venetian fashion. A new type of glass that worked well for copper-wheel engraving was perfected in Bohemia (now part of the Czech Republic) and Germany in the mid-1600’s, and a flourishing industry developed.

Glassmaking became important in England during the 1500’s. By 1575, English glassmakers were producing Venetian-style glass. In 1674, an English glassmaker named George Ravenscroft patented a new type of glass in which he had changed the usual ingredients. This glass, called lead glass, contains a large amount of lead oxide. Lead glass, which is especially suitable for optical instruments, caused English glassmaking to prosper.

Early American glass.

The first factory in what is now the United States was a glass plant built at Jamestown, Virginia, in 1608. The venture failed within a year because of a famine that took the lives of many colonists. The Jamestown colonists tried glassmaking again in 1621, but an Indian attack in 1622 and the scarcity of workers ended this attempt in 1624. The industry was reestablished in America in 1739, when Caspar Wistar built a glassmaking plant in what is now Salem County, New Jersey. This plant operated until 1780.

Wistar is one of the great names of early American glass. The second great American glassmaker was Henry William Stiegel, also known by his nickname, “Baron” Stiegel. Stiegel made clear and colored glass, engraved and enameled glass, and the first lead glass produced in North America. A third important American glassmaker was John F. Amelung, who became best known for his elegant engraved glass.

Another important early American glass, Sandwich glass, was made by the Boston and Sandwich Glass Company, founded by Deming Jarves in 1825. It was long believed to be the first company in America to produce pressed glass. But the first was actually the Bakewell, Page, and Bakewell Company of Pittsburgh, Pennsylvania, which began to make pressed glass earlier in 1825. These two companies and many others soon made large quantities of inexpensive glass, both pressed and blown. Every effort was made to produce a “poor man’s cut glass.” In lacy Sandwich, for example, glassmakers decorated molds with elaborate designs to give the objects a complex, lacelike effect.

In the early 1800’s, the type of glass in greatest demand was window glass. At that time, window glass was called crown glass. Glassmakers made it by blowing a bubble of glass, then spinning it until it was flat. This process left a sheet of glass with a bump called a crown in the center. By 1825, the cylinder process had replaced the crown method. In this process, molten glass was blown into the shape of a cylinder. After the cylinder cooled, it was sliced down one side. When reheated, it opened up to form a large sheet of thin, clear window glass. In the 1850’s, plate glass was developed for mirrors and other products requiring a high quality of flat glass. This glass was made by casting a large quantity of molten glass onto a round or square plate. After the glass was cooled, it was polished on both sides.

Bottles and flasks were first used chiefly for whiskey, but the patent-medicine industry soon used large numbers of bottles. The screw-top Mason jar for home canning appeared in 1858. By 1880, commercial food packers began to use glass containers. Glass tableware was used in steadily increasing quantities. The discovery of petroleum and the increased use of the kerosene lamp in the early 1860’s led to a demand for millions of glass lamp chimneys. All these developments helped to expand the market for glass.

Modern glassmaking.

Changes in the fuel used by the glass industry affected the location of glass factories. In the early days when wood was used as fuel, glassworks were built near forests. By 1880, coal had become the most widely used fuel for glassmaking, and glassmaking operations were near large coal deposits. After 1880, natural gas became accepted as the perfect fuel for melting glass. Today, most glass manufacturing plants are near the major sales markets. Pipelines carry petroleum and natural gas to the glass plants.

After 1890, the development, manufacture, and use of glass increased rapidly. The science and engineering of glass as a material are now so much better understood that glass can be tailored to meet an exact need. Any one of thousands of compositions may be used. Machinery has been developed for precise, continuous manufacture of sheet glass, tubing, containers, bulbs, and a host of other products.

New methods of cutting, welding, sealing, and tempering, as well as better glass at lower cost, have led to new uses of glass. Glass is now used to make pipelines, cookware, building blocks, and heat insulation.

Ordinary glass turns brown when exposed to nuclear radiation, so glass companies developed a special nonbrowning glass for use in observation windows in nuclear power plants. More than 10 tons (9 metric tons) of this glass are used in windows in one nuclear power plant. In 1953, automobile manufacturers introduced fiberglass-plastic bodies. Today, such materials are used in architectural panels to sheathe the walls of buildings. They are also used to make boat hulls and such products as missile radomes (housings for radar antennas). Other types of glass have been developed that turn dark when exposed to light and clear up when the light source is removed. These photochromic glasses are used in eyeglasses that change from clear glasses to sunglasses when worn in sunlight.

During the late 1960’s, glass manufacturers established collection centers where people could return empty bottles, jars, and other types of glass containers. The used containers are recycled—that is, broken up and then melted with silica sand, limestone, and soda ash to make glass for new containers. Glass can be recycled easily because it does not deteriorate with use or age. In addition to the collection centers, some communities have set up systems to sort glass and other reusable materials from regular waste pickups.

In the 1970’s, optical fibers were developed for use as “light pipes” in laser communication systems. These pipes maintain the brightness and intensity of light being transmitted over long distances. Types of glass that can store radioactive wastes safely for thousands of years were also developed during the 1970’s.

The late 1900’s brought important new specialty glasses. Among the new specialty glasses were transparent glass ceramics, which are used to make cookware, and chalcogenide glass, an infrared-transmitting glass that can be used to make lenses for night vision goggles.