Grain elevator is a tall building equipped with machinery for loading, unloading, cleaning, mixing, and storing grain. These buildings are familiar sights in farm areas and in ports where grain is stored before shipment.

The term grain elevator is also used to mean the machine that lifts grain from a train or a ship to the storage bins. Some of these machines consist of systems of buckets that can unload the largest grain-carrying ships in a matter of hours.

Kinds of grain elevators.

There are two general types of grain elevators–country elevators and terminal elevators.

Country elevators

are found in nearly every town in grain-producing areas. These smaller elevators receive grain from farmers and generally store it for only short periods. The grain is cleaned in country elevators, and then graded before it is loaded in railroad cars and shipped to the large markets. Country elevators may be owned by independent business people, by farm cooperatives, or by grain elevator companies.

Terminal elevators

stand at large grain markets and shipping centers such as Chicago; Duluth, Minnesota; Kansas City, Missouri; Minneapolis, Minnesota; and New Orleans. Most terminal elevators are larger than country elevators. In these elevators, grain is stored for the use of millers or to await shipment on the Great Lakes or overseas. Nearly all terminal elevators hold over 1 million bushels (35,000 cubic meters) of grain. One elevator in Wichita, Kansas, can hold 301/2 million bushels (1.1 million cubic meters).

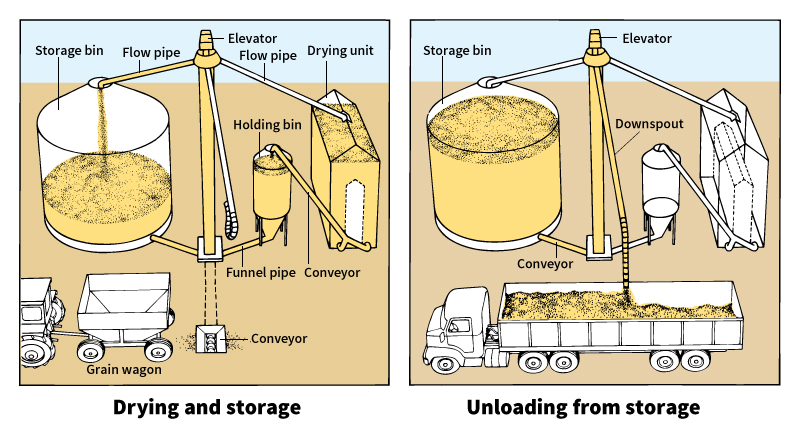

How grain elevators operate.

Grain elevators were once made of wood. Today, country elevators are often concrete or steel, and terminal elevators are concrete. Most grain elevators are over 100 feet (30 meters) high. Weighing and cleaning occur above the storage bins. This area is called the cupola or headhouse.

Railroad cars are unloaded at grain elevators by means of devices that tip a boxcar so that the grain runs out of the doors. Elevators for loading and unloading ships have marine legs on the dock side. To unload a vessel, the hatches are first removed, and the marine legs are lowered into the holds. Electrically operated buckets in the legs quickly raise the grain to the top of the cupola. From there, the grain goes through a scale hopper that weighs it, and then through a cleaner to the storage bins. A huge shipping port elevator can load vessels at the rate of 100,000 bushels (3,500 cubic meters) per hour.

See also Wheat (Transporting and storing wheat) .