Ice cream is a popular frozen dairy food. It consists mostly of milk products, sugar, and flavorings. Ice cream may be served by itself or with cake, pie, or other pastries. It also is used in making milk shakes, sodas, cake rolls, and sundaes. Manufacturers make ice cream in many flavors. About one-third of the ice cream sold in the United States is vanilla. Chocolate and Neapolitan (layers of different flavors) rank next in popularity.

The United States produces about 1.4 billion gallons (5.3 billion liters) of ice cream annually. Almost one-tenth of the nation’s milk supply is used to produce ice cream and other frozen desserts. These desserts include ice milk, sherbet, and frozen yogurt. About 7 quarts (6.6 liters) of milk are needed to make 4 quarts (3.8 liters) of ice cream.

Ice cream is served in many parts of the world, but Americans eat more of it than do the people of any other country. Americans eat an average of about 23 quarts (21.8 liters) of ice cream annually.

The composition of ice cream.

The milk products in ice cream make it rich in calcium, phosphorus, protein, and vitamin A. Ice cream is also high in calories because of the carbohydrates and fats it contains.

The Food and Drug Administration (FDA) and the individual U.S. states have established standards for the content of ice cream and related frozen desserts. For example, milk fat and other milk solids must make up at least 20 percent of the weight of ice cream. Ice milk consists of a minimum of 11 percent milk solids. Philadelphia style ice cream is primarily made with milk or cream and sugar. French style ice cream has the same ingredients, plus 1.4 percent egg yolk solids. Egg yolks are emulsifiers—that is, ingredients that help bind other ingredients together. Because of the egg yolks, French style ice cream typically tastes richer than does Philadelphia style ice cream.

Sherbet contains about twice as much sugar as does ice cream, plus a minimum of 2 percent milk solids. Frozen yogurt contains milk fat and other milk solids. Frozen yogurt producers ferment (ripen) these milk products by adding bacteria that change milk sugar into acid.

How ice cream is made.

Most of the ice cream consumed today comes from commercial manufacturing sources. But some people still enjoy making their own ice cream at home. The first step in making ice cream consists of combining the two chief ingredients—milk products and sugar—to form a mix.

Commercial production.

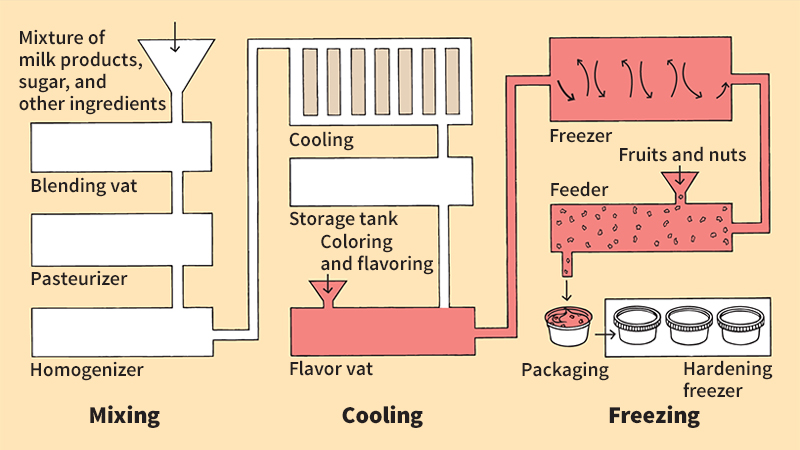

In an ice cream plant, the mix is blended in a huge vat and then pasteurized. Next, the mix is homogenized, a process that breaks down the fat particles. Homogenizing the mix helps give ice cream a smooth texture. The mix is then pumped through a cooler, where its temperature drops to about 35 °F (2 °C). Then it is put into a storage tank for three or four hours to “age.” Flavorings and colorings are added, and then the mix is frozen.

Most commercial freezers use liquid ammonia to maintain a temperature of about –22 °F (–30 °C). The mix freezes against the sides of the freezer, which has fanlike blades that rotate at a high speed. The blades scrape the frozen mix from the sides of the freezer and whip air bubbles into it. If air were not added, eating ice cream would be like chewing sweetened ice cubes. The air increases the volume of the mix. The difference in volume before and after air is added is called overrun. Ice cream packaged for home use has about 80 percent overrun. Sherbet has about 35 percent overrun.

There are two types of commercial freezers. Most manufacturers use a continuous freezer, which freezes the mix in less than a minute. The other type, called a batch freezer, freezes it in three to eight minutes.

Fruit, nuts, and candy may be added to ice cream before it is packaged. After packaging, the product is placed in a hardening room. Hardening takes at least 12 hours at temperatures ranging from –10 to –20 °F (–23 to –29 °C). Most of the water in the ice cream freezes during this period, so that the product becomes hard for storage.

Home production.

Homemade ice cream has less overrun and is not as smooth as commercial ice cream. Most home ice cream makers hold from 4 to 8 quarts (3.8 to 7.6 liters) of mix. Freezing temperatures are created by placing the mix in a freezing compartment surrounded by a gel or by salt and cracked ice, with a temperature of around 23 °F (–5 °C). The mix is stirred by blades driven by a hand crank or by electric power.

Another type of ice cream can be made in an ice cube tray of a refrigerator. The mix is poured into the tray. After partially freezing, it is scraped out and put into a cold mixing bowl. Then the mix is beaten with an electric mixer, returned to the tray, and put in the freezer compartment of the refrigerator for hardening.

History.

No one knows when ice cream was first made. In 1295, the Italian trader Marco Polo returned to Europe from China and may have brought recipes for water ices. During the 1600’s, Europeans used a combination of ice, snow, and a mineral called saltpeter to freeze mixtures of cream, fruit, and spices.

British colonists probably brought recipes for ice cream to America in the early 1700’s. Ice cream became a popular luxury food, but almost all of it was made at home until 1851. That year, Jacob Fussell, a Baltimore milk dealer, established the first ice cream plant. Ice cream became a national favorite during the early 1900’s after soda fountains introduced sodas, sundaes, and other new ways of serving it. Ice cream cones were first served at the 1904 World’s Fair in St. Louis. Ice cream bars appeared in 1921. Ice cream production increased greatly in the late 1940’s. During the first decade of the 2000’s, the United States produced about 1.4 billion gallons (5.3 billion liters) of ice cream yearly.