Ignition is any system that sets fire to a mixture of fuel and air to create power in an engine. The two main kinds of ignition are spark and compression. Spark ignition systems are used in the gasoline engines found in most automobiles. Diesel engines use compression ignition. This article discusses spark ignition. For information about compression ignition, see Diesel engine .

In a gasoline engine, spark plugs ignite the fuel-air mixture. One plug is mounted in each of the engine’s cylinders. The plug has two terminals that project into the cylinder’s combustion chamber. The ignition system causes a high-voltage electric current to “jump” from one terminal to the other. This “jump” creates the spark. Most spark ignition systems create electric current by means of a 12-volt storage battery. Others use a device called a magneto (see Magneto ). Battery ignition is used in automobiles.

Parts of an ignition system.

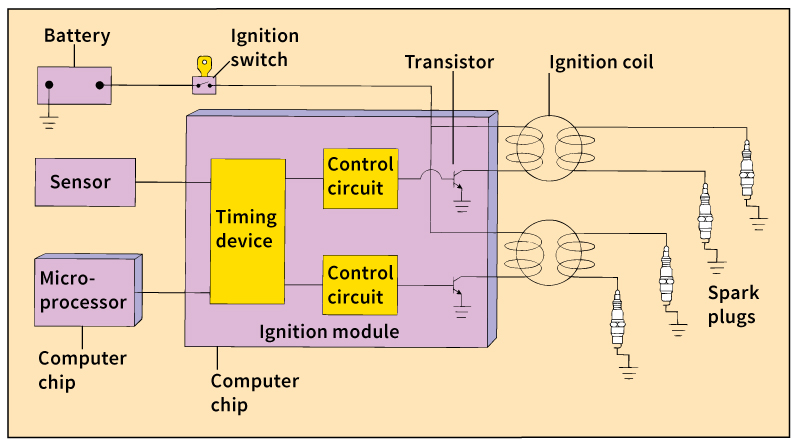

There are two main kinds of battery ignition systems: (1) direct-fire, or distributorless, and (2) conventional electronic. Both systems consist of an electric circuit that includes a battery; an ignition switch, which is operated by the ignition key; at least one ignition coil; at least one transistor (electronic switch); and the same number of spark plugs as there are engine cylinders. Both systems also have timing devices that cause a spark to be created just as the fuel-air mixture in a cylinder becomes tightly compressed and ready for burning.

An ignition coil is a kind of induction coil, a device that uses a low-voltage current to produce a high-voltage current (see Induction coil ). The ignition coil consists of an iron core called a magnetic core and two sets of wires called windings. The primary winding is wound around the magnetic core and connected to the battery. This winding has from 100 to 200 turns (loops) of wire. The wire is about as thick as a straight pin. The secondary winding, which is also wrapped around the core, connects to the spark plugs. This winding has from 15,000 to 20,000 turns of wire. The wire is about as thick as a human hair. The two windings are insulated so that current cannot flow from one winding to the other.

In systems in which two spark plugs are connected to the secondary winding, both plugs fire at the same time. In one cylinder, the fuel-air mixture is ready for burning. The other cylinder contains no fuel. This cylinder’s plug fires as the last of the exhaust fumes from the previous firing are being forced out of the cylinder. The firing in this cylinder uses little energy.

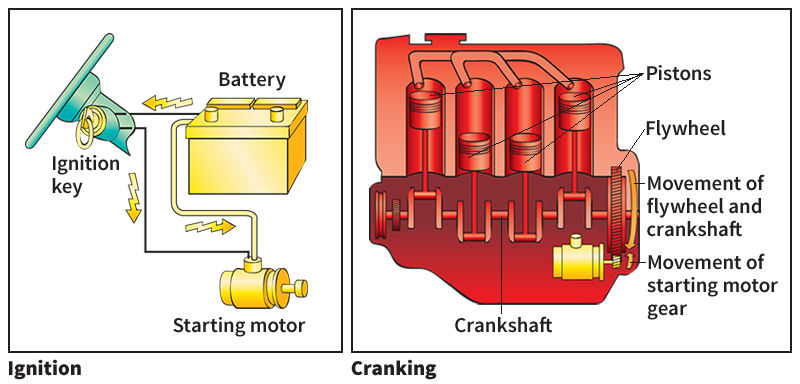

How an ignition system operates.

When the driver of the car turns the ignition key to start the car, the ignition switch closes. Low-voltage current flows from the battery to the primary winding. This current creates a magnetic field within and around the magnetic core. Next, a timing device causes the transistor to open the circuit that contains the primary winding. As a result, the current in this winding stops. The magnetic field therefore collapses, generating a high-voltage current in the secondary winding. This current creates a spark in the plug or plugs that are connected to this winding. The timing device then causes the transistor to close the primary circuit, and the process repeats.

The direct-fire ignition system

is used in most modern cars. For every two cylinders or, in some cases, for each cylinder, this system has one ignition coil, one transistor, and one electronic control circuit. In direct-fire systems, each spark plug is connected directly to the secondary winding. An ignition module contains the control circuits and transistors. The module is linked to a vehicle electronic control unit, also called an electronic control module. This unit contains a microprocessor, a tiny computer chip that controls many of the car’s systems. This chip sets the timing of the spark based on engine speed, load (resistance the engine must overcome), and other factors, and sends instructions to the ignition module. A sensor indicating the position of the crankshaft determines the exact time for firing a spark. The crankshaft is a mechanical part that transforms the up-and-down motion of pistons into the rotary motion of the drive train.

The conventional electronic ignition system

is found in most cars manufactured from the 1970’s to the mid-1980’s. It has a single ignition coil and transistor. A device called a distributor controls the firing of one plug at a time in a specific sequence. Inside the distributor, a small rotating arm called a rotor sends the high-voltage current through wires connected to the spark plug in the cylinder ready for combustion. Conventional electronic ignition systems are less reliable and more difficult to maintain than direct-fire ignition systems.

Development of ignition systems.

Before the 1970’s, ignition systems were largely mechanical. The distributor contained a rotating, many-sided wheel called a breaker cam that continually opened and closed electrodes called breaker points to interrupt the low-voltage current. In the mid-1970’s, an electronically controlled transistor replaced the points. Later, a magnetic pulse generator replaced the cam. In the early 1980’s, many ignition systems began to use a microprocessor instead of a mechanical device to regulate spark timing. Carmakers introduced direct-fire ignition systems in the mid-1980’s.

See also Gasoline engine (The ignition system) ; Induction coil .