Offset is a printing process in which an image is first transferred from a printing plate to a rubber blanket covering a rotating cylinder. The impression is then transferred to paper by the pressure of other cylinders. The term offset describes the transfer, or offsetting, of the ink from a printing plate to rubber and then to paper.

All ordinary offset printing is done from the metal surfaces of lithographic plates (see Lithography ). The material to be printed is transferred onto the plates through a photographic process or directly from computer files. The plates are chemically treated so only the image areas of the print will take up the ink. Other types of plates can be used for offset printing. Some printing is done from ordinary type and cuts, some from thin plastic relief or letterpress plates, some from gelatin surfaces, and some from intaglio plates, metal sheets or cylinders that carry the ink in sunken lines.

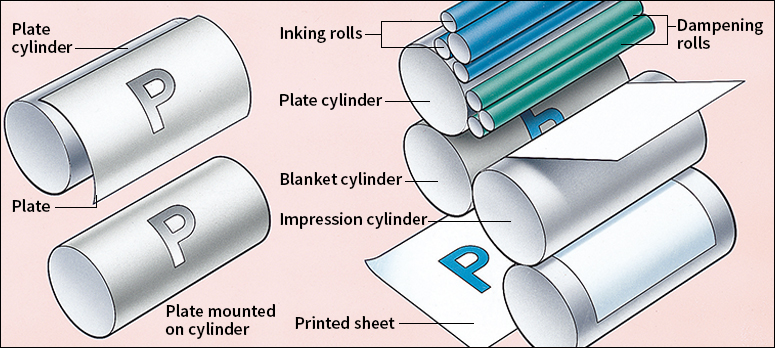

Offset lithography is usually done on a press having three cylinders. A lithographic plate is wrapped around the first cylinder. This plate is a sheet of aluminum or zinc about as thick as heavy paper. The plate prints on the second cylinder, which is covered by the rubber blanket. The impression on the rubber is then printed on the paper carried by the third cylinder. The third cylinder is equipped with steel fingers, called grippers, to hold the paper in position while it is squeezed against the rubber surface. Three-cylinder presses of this type can turn out tens of thousands of impressions an hour.

These cylinders are almost hidden while the press is in operation. They are covered by a great number of rollers which supply the lithographic plate with ink and water. The cylinders are also concealed by a mechanism for feeding and removing sheets or rolls of paper.

Offset has several advantages over other types of printing. The elastic rubber transfers the impression to a rough surface as easily as to a smooth one. This makes it possible to print on rough paper, as well as on tin, plastic, and other materials. Another advantage of offset is that the rubber on the cylinder fits easily to uneven surfaces. This reduces the time workers must spend preparing the presses for printing.

Offset was developed in the early 1900’s in the United States. It has been applied to almost every class of printing, from the cheapest to the most expensive. Offset has replaced the older forms of lithography in which the impression was made directly on the paper from stone or metal plates. An offset press can turn out bank notes, letterheads, magazines, mail-order catalogs, newspapers, posters, and stock certificates. The offset press is used to print many daily newspapers. Offset is combined with rotogravure, another printing process, to make colored illustrations that are clear and delicate. It is also used for facsimile reproduction of old books.

Offset is still being improved and applied to new purposes. The wearing qualities of the lithographic plates are being improved. Offset presses have been designed to print on a web (roll) of paper. In a process called perfecting, paper on this web press is passed between two rollers covered with rubber blankets, printing on both sides at the same time.