Polystyrene is a glasslike, lightweight plastics material used in a variety of goods. Products made of polystyrene include food packaging, insulation, housewares, and automobile parts.

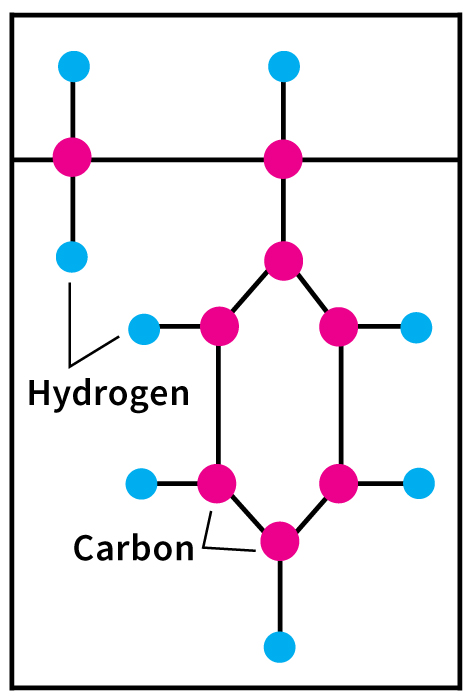

Polystyrene is a synthetic polymer. A polymer is a long, chainlike molecule. The “links” are repeating patterns of simple groups of atoms called monomers. Polystyrene is made from styrene monomers, each consisting of eight carbon atoms and eight hydrogen atoms. Polystyrene is a thermoplastic—that is, it softens and melts at high temperatures (see Plastics (Types of plastics) ).

Polystyrene is fairly strong, easy to work, and inexpensive. A common way to make polystyrene is to heat styrene monomer to about 360 °F (180 °C). Manufacturers produce polystyrene plastics by adding fillers, colorings, and plasticizers (chemicals that help soften the material) to the polymer.

A number of methods are used to make products of the plastic. Extrusion (pushing melted plastic through an opening) makes a film used in wall coverings. A combination of extrusion and thermoforming (using a vacuum to draw hot plastic sheets into a mold) produces food containers and refrigerator parts. Injection molding (forcing melted plastic into a mold) creates auto parts and panels for cabinets. Blow molding (forcing air and plastic into a mold) produces polystyrene foam, a lightweight material containing tiny bubbles of air. This material is used in ice chests, disposable cups, packaging material, and building insulation.

Polystyrene plastics are difficult to break down into their basic ingredients for recycling. Instead, recyclers grind them into powders that are used as fillers.

Dow Chemical Company became the first producer of polystyrene in 1930. In the mid-1950’s, the company introduced polystyrene foam under the registered trade name Styrofoam.