Pottery is a type of decorative or useful ware made of baked clay. It ranges from valuable works of art created by professional potters to dinnerware, vases, and other simple household items. The word pottery also means a factory that makes pottery.

A piece of pottery may be mass-produced. Or it may be the only one of its kind. Since ancient times, potters have shaped and fired (baked) clay to make pottery. Some pottery in museums is thousands of years old and still in good condition.

Pottery belongs to a large group of items called ceramic products. Such products are made from materials known as ceramics. Ceramic products, in addition to pottery, include bricks, cement, and sewer pipes. For more information on the ceramics industry, see the World Book article on Ceramics.

Types of pottery

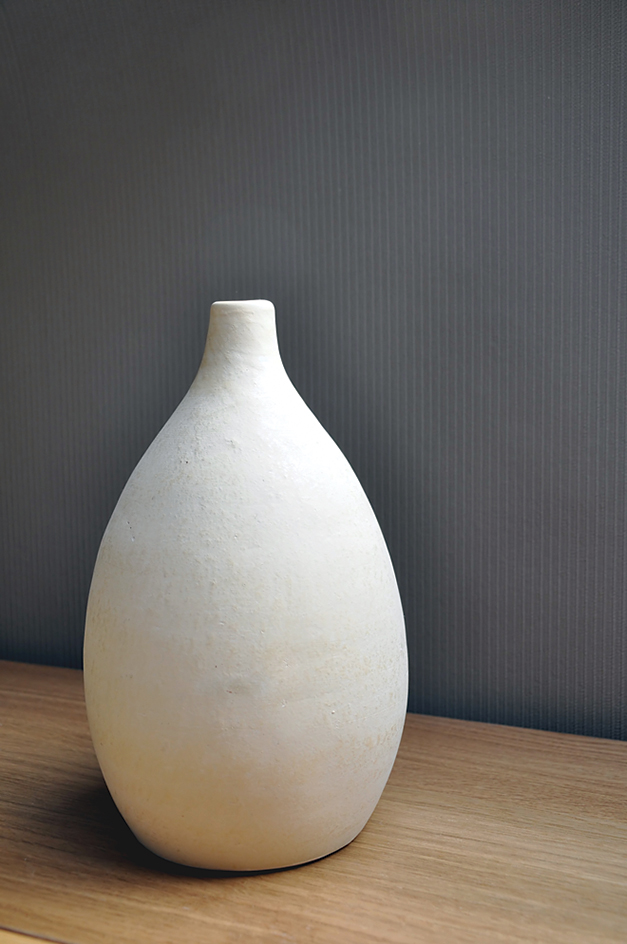

The three major types of pottery are earthenware, stoneware, and porcelain. Pottery is classified according to the mixture of clays that it contains and the temperature at which the mixture is fired. The firing temperature affects both appearance and strength.

Earthenware

is made largely from a mixture of earthenware clays. Such clays are found in soil in all parts of the world. Many people prefer earthenware because of the colorful glaze (glassy coating) which is applied to it. This pottery, like most bright, colorful glazes, is baked at a low temperature. Other types of pottery are less colorful because they are fired at a high temperature. The heat harms most colorful glazes. Earthenware breaks and chips more easily than other types of pottery.

Stoneware

is made mostly from a mixture of stoneware clays. These clays are found in the soil of scattered areas of the United States. Potters fire such clays at high temperatures. The heat causes the surface of stoneware to become glossy. For this reason, many potters do not glaze it. Stoneware is stronger and heavier than earthenware. Like earthenware and some kinds of porcelain, it is opaque—that is, light cannot shine through it.

Porcelain

is the purest and the most delicate type of pottery. There are two types of porcelain. Hard-paste porcelain is fired at high temperatures. Soft-paste porcelain, which includes chinaware, is fired at lower temperatures.

Potters make hard-paste porcelain from a mixture of petuntse (a type of feldspar found only in China) and kaolin. Kaolin is a fine white clay. Most porcelain fires to a delicate shade of white. Light can shine through a thin piece of porcelain. Soft-paste porcelain is made from kaolin and a mixture of substances that may include flint. See Kaolin.

How pottery is made

There are four basic steps in making pottery—preparing the clay, shaping the clay, decorating and glazing, and firing.

Preparing the clay.

Potters prepare clay by pressing and squeezing it with their hands or by mechanical methods. This treatment makes clay soft and smooth. It eliminates air bubbles that could cause the clay to crack during the firing process.

Shaping the clay

can be done by various methods. Some of these methods involve hand building. In hand building, potters use only their hands to shape the clay. The easiest hand-building method consists of pinching the clay into the desired form. Many beginning potters use this process to make small bowls called pinch pots. Another method of hand building, called solid forming, consists of shaping a sculpture out of a lump of clay.

The most common ways of shaping clay include the coil method, the slab method, the mold method, and the wheel method. The first two methods involve hand building. The second two require equipment. A potter may use a combination of these methods. For example, the potter might form the body of a teapot on a potter’s wheel. He or she might use a hand-building method to make the handle and spout.

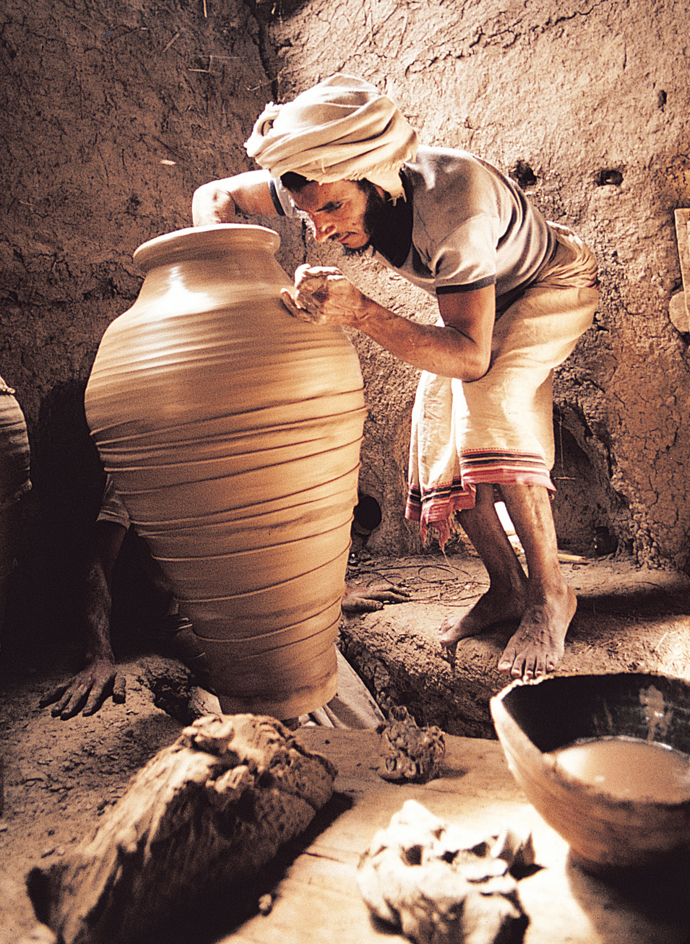

The coil method

is one of the oldest and simplest ways of making pottery. After preparing the clay, the potter shapes part of it into a flat piece that will be the base of the ware. The remaining clay is rolled into long strips. Using the base piece as a foundation, the potter coils the strips of clay on top of one another.

The coils must be attached together to make the pottery strong. The potter attaches each coil layer to the next with a creamy substance called slip. Slip serves as a cement. It is made by adding water to clay. Potters always smooth the inside surface of a piece of coil pottery. They may also smooth the outside surface, depending on the design of the piece.

The slab method

forms pottery from flat pieces of clay. The potter shapes the clay into flat slabs by pounding it with the fists or by flattening it with a rolling pin. Using one slab as the base, the potter places other slabs at right angles to it to form the sides of a piece of pottery. The slabs are then attached together with slip. Slabs may be difficult to work with, especially if they are large. For this reason, the potter may let the slabs harden slightly before fastening them together.

The mold method

is used to produce identical pieces of pottery. One technique of mold shaping, called slip casting, is used to turn out a large number of pieces of hollow pottery. In slip casting, the potter pours slip into a mold and lets part of it dry. The slip nearest the sides of the mold thickens quickly. After a few minutes, the slip in the middle of the mold is poured out, leaving the thicker slip attached to the sides. The thick slip dries into a finished piece of pottery.

Mold shaping can also be done by jiggering and pressing. Jiggering involves a preformed edge or blade. The edge or blade presses down on a piece of clay on a mold to a preset thickness while turning on a wheel. In pressing, the potter puts the clay between two pieces of plaster that form a mold. The clay is squeezed into the desired shape by pressing the pieces together.

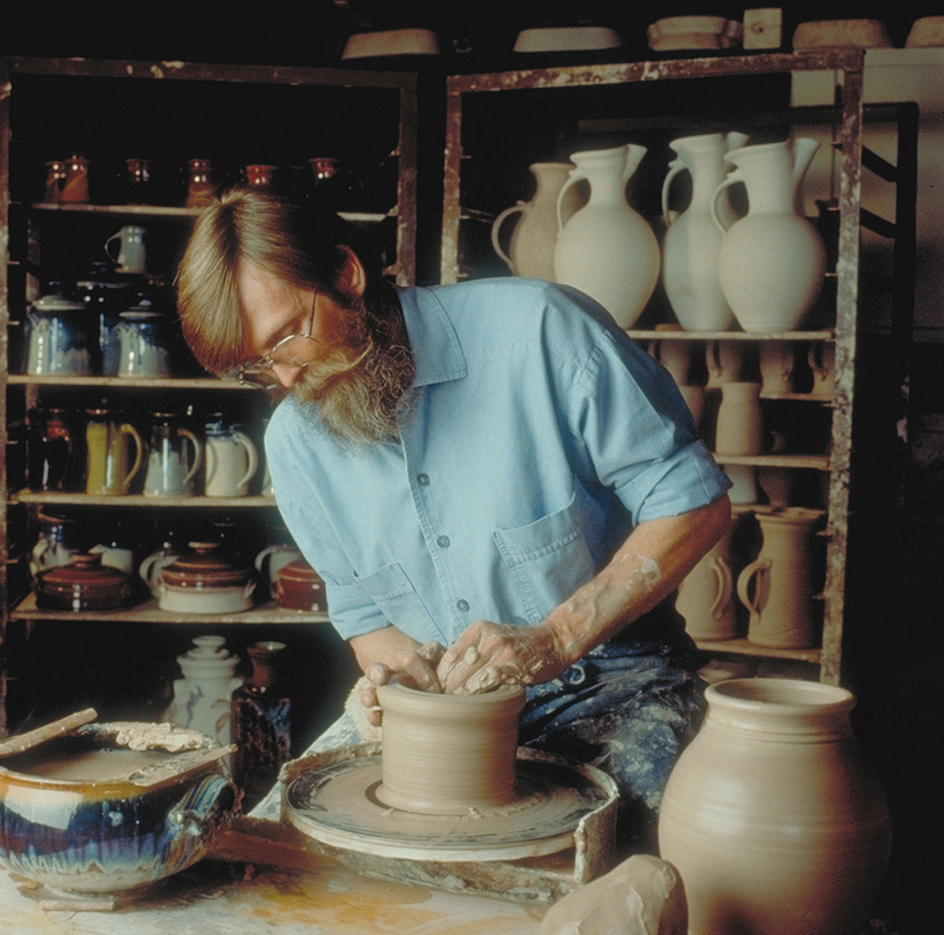

The wheel method

involves the use of a potter’s wheel. This device consists of a round, flat, metal surface that turns while the potter shapes clay on it. Most wheels are electrically powered. They turn when the potter presses a foot pedal.

As the wheel turns, the potter pushes the thumbs or other fingers into the center of the spinning clay. This action forms the clay into a pot that has low, thick sides. The potter shapes the sides into the desired form by pressing one hand on the inside and one hand on the outside of the spinning pot.

Decorating and glazing.

Potters can put simple decorations on their ware by pressing their fingers into the soft clay or by scratching lines into it. Elaborate designs can be drawn on pottery by using colored substances that will not be damaged by heat during firing. Such substances include enamel, glaze, and slip.

One type of pottery decoration is called sgraffito. In this method, the potter puts a thin layer of colored substance on a piece of pottery of a different color. The potter then uses a sharp tool to scratch through the colored outer layer. The scratching allows the color of the clay body to form a design in the actual surface of the pottery beneath. Potters can make attractive decorations by filling in the sgraffito grooves with substances of various colors.

Glazing is used not only to decorate, but also to smoothen and waterproof pottery. Potters have developed many types and colors of glaze. They apply it in several ways. Methods of application include brushing, pouring, or spraying the glaze onto pottery. After a piece of pottery is glazed, the potter fires it. Some types of pottery must be fired before being glazed. After glazing, they are fired again to bake the glaze. A few kinds of pottery are usually not glazed. They include a stoneware called jasper and an earthenware called terra cotta (see Terra cotta).

Firing

makes pottery hard and strong. It also makes glaze stick to clay. It hardens the glaze as well. Pottery is fired in an oven called a kiln.

History

Early pottery

consisted of figurines and simple household utensils. People in East Asia were making pottery as early as 18,000 B.C. In the Middle East and areas around the Mediterranean Sea, pottery making began by about 8000 B.C. The Egyptians, about 3000 B.C., became the first people to glaze pottery.

By about 1600 B.C., people on the island of Crete were producing beautiful pottery. They decorated it with curved designs and pictures of animals. Cretan methods of making and decorating pottery influenced Greek ware. The ancient Greeks made graceful pottery. They decorated it with vivid designs.

Peoples in other parts of the world also developed pottery skills. In North and South America, many Indian tribes developed the art of making pottery. Tribes that created especially beautiful pottery included the Inca, the Maya, and the Pueblo. Between about A.D. 600 and 950, artists in the African kingdoms of Ife and Benin used sculptured pottery figures as models for large, metal statues.

In China, potters had started to use the pottery wheel before 3000 B.C. Chinese potters learned to make porcelain, probably during the Han dynasty (206 B.C.-A.D. 220). Potters of the Song dynasty (A.D. 960-1279) experimented with many pottery shapes and glazes. They created some of the loveliest pottery in history.

About 1200, the Chinese began to export pottery to the countries of the Near East. The potters of these nations combined Chinese styles with their own. They developed new forms and designs. One of the new forms resulted in a type of colorfully glazed pottery called majolica (see Majolica).

Pottery of the 1700’s and 1800’s

featured developments in Europe and the New World. The nations of the Middle East began to export much of their pottery, including majolica, to Europe. European pottery-making centers, especially in Italy, copied the Middle Eastern pottery. The European centers introduced new styles of their own as well. These styles included delft and faïence (see Delft; Faïence).

In 1708, Johann Friedrich Böttger, a German chemist, became the first European to discover how to make porcelain. The Chinese had refused to share the secret of porcelain making. After European industrialists established factories to make porcelain, they also kept the method of porcelain making a secret. Many European wares greatly influenced pottery making. These respected wares included Meissen, Sevres, Wedgwood, and Worcester.

When Europeans settled in the New World, they brought their own styles of pottery making. Later, pottery in the United States followed European styles until 1880. That year, Maria Longworth Nichols, , a potter in Cincinnati, founded the Rookwood Pottery to produce art pottery. Nichols is better known by her married name of Mrs. Bellamy Storer. This plant produced pottery that reflected local ideas and tastes. Most of the Rookwood pottery had colorful glazes and many types of decoration.

Modern styles of pottery

developed during the 1900’s. These styles resulted from the desire of potters to create individual, personal ware. Today, most studio potters use methods of shaping and decorating that were used before the 1800’s. Developments in pottery design that take place in one part of the world quickly reach and influence potters in other regions.

Since the early 1900’s, people in many parts of the world have developed an interest in pottery making as a hobby. Amateur potters can go to specialized schools and pottery studios to learn the craft. Exhibitions encourage amateur and professional potters to show their wares and to exchange ideas.