Rope consists of strands of yarn or wire that have been twisted together. It ranges in size from 3/16 inch (4.8 millimeters) to more than 6 inches (152 millimeters) in diameter. Rope that is less than 3/16 inch thick is called twine or cord. Cordage is the general term for rope, twine, or cord made from yarn.

People have made and used ropes since prehistoric times. Today, ropes are used for lifting loads, for towing, and for many other purposes. There are three kinds of rope, depending on the material from which they are made: (1) natural-fiber rope, (2) synthetic-fiber rope, and (3) wire rope.

Natural-fiber rope

is made from fibers that come from plants. The natural fiber most widely used in rope is manila, a hard fiber taken from the leaf stems of the abacá plant. Abacá grows mainly in the Philippines, and most manila rope is manufactured there. Manila rope has great strength and good resistance to wind, rain, and sun. See Abacá .

Other natural fibers used in rope include sisal and henequen. Sisal comes from the leaves of the sisal plant, which grows mainly in Brazil and eastern Africa. It is a hard fiber that has about 80 percent of the strength of manila. Henequen is taken from the henequen plant, which grows chiefly in Mexico. Henequen is not as strong as sisal and is used primarily in twine and lower grades of rope. See Henequen ; Sisal .

In the past, much rope was also made from soft natural fibers, such as hemp and jute. Today, soft fibers are used mostly in twine and in the art of macrame. See Hemp ; Jute ; Macrame .

Synthetic-fiber rope

is stronger, lighter, and, in most cases, more flexible than natural-fiber rope. Synthetic fibers have greater resistance to chemical damage and do not rot, as do natural fibers.

The first synthetic-fiber rope was made from nylon during World War II (1939-1945) and used for parachute cords and glider towropes. Nylon rope is almost three times as strong as manila rope. The great elasticity of nylon rope makes it the best rope for towing and anchor lines. Rope made from polyester fibers is expensive, but it is the best rope for general use. It has almost the same strength as nylon rope but does not have as much stretch. Polyester rope resists damage from abrasion (scraping) and the sun’s ultraviolet rays better than any other synthetic-fiber rope. Polypropylene rope is about 50 percent stronger than manila rope. Special chemical compounds must be added to polypropylene to give it ultraviolet resistance.

Manufacturers make extremely strong rope from synthetic fibers called aramids. Rope made from aramid fibers can be used under hotter conditions than other synthetic fibers because it has a high melting point. It also resists stretching.

Manufacturers also produce ropes that combine the desirable features of two or more synthetic fibers. A common combination—polyester and polypropylene—provides a cheaper substitute for polyester.

Wire rope

consists of steel wires twisted together. It is stronger and wears better than most fiber rope, but it is much heavier and not as flexible as rope made from fibers. Wire rope, often called cable, is used in operating such equipment as elevators, oil well derricks, and shovels used in construction work.

How rope is made.

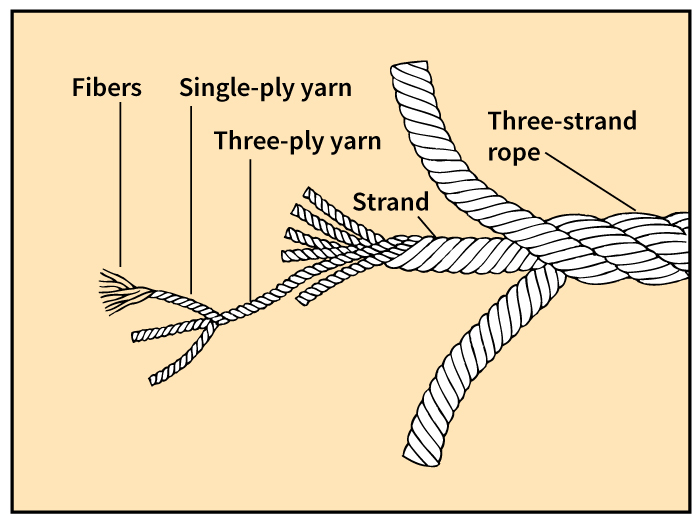

Ropes must be carefully designed to meet such usage requirements as abrasion resistance, chemical and ultraviolet resistance, strength, stretch, and weight. Rope manufacturers buy bales of natural fibers from fiber brokers. A machine called a card combs the fibers and lays them parallel, forming a continuous ribbon. The ribbon is drawn out until it is thin enough for spinning. A machine spins the ribbon into yarn, and strands are made by twisting together two or more yarns. Three or more strands are laid (twisted) together to form rope.

Manufacturers buy most synthetic fibers in filament form. A machine called a twister twists the long filament yarns into plied yarns, which are then made into rope in the same way as natural fiber yarn.

Most rope has three strands, but four- and eight-strand ropes are also popular. Another common type, called cable-laid rope, consists of three three-strand ropes closed (wrapped) together.

Manufacturers make wire rope by twisting a number of wires together to form strands and then closing the strands around a core. The strongest wire ropes have wire cores.